Bidirectional stretching polylactic acid / montmorillonoid, and preparation method and application thereof

A biaxially stretched, montmorillonite technology, used in transportation and packaging, sustainable manufacturing/processing, flexible coverings, etc., can solve problems such as short shelf life of barrier properties, and achieve excellent performance, good degradability and reproducibility. The effect of improving stretchability and barrier properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

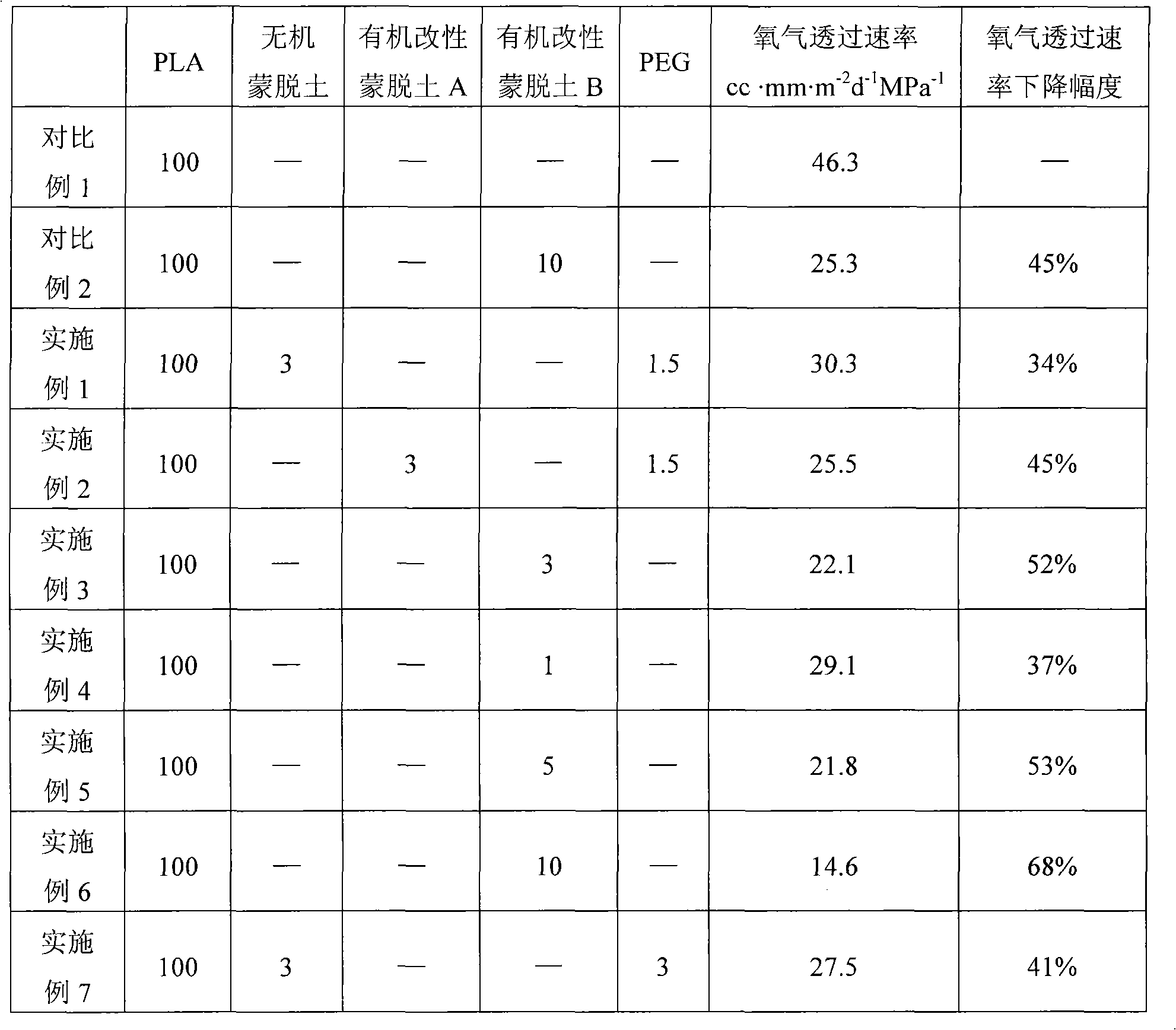

[0035]100 parts of polylactic acid, plus 3 parts of inorganic montmorillonite, were dried in a vacuum oven for 8 hours, and then put into high-speed stirring for 2 minutes together with 1.5 parts of polyethylene glycol (PEG). Put it into the extruder to granulate, set the temperature of each section from the barrel to the head at 180-190-190-190-190-195°C, and the screw speed at 350rpm. After granulation, the granules were dried in a vacuum oven at 80° C. for 10 hours. A tape casting machine is used for casting. The temperature of each section of the casting machine barrel from the hopper to the die head is 175-170-170-180-180° C., and the screw speed is 8.5 rpm. The sheet obtained by casting was cut into square pieces of 9.3×9.3 cm, and stretched in a bidirectional stretching machine to prepare a BOPLA film. The temperature of the stretching furnace was 75°C, and longitudinal stretching was performed first, with a stretching ratio of 3.5. Then carry out transverse stretching...

Embodiment 2

[0037] Other conditions are the same as in Example 1, but replace the inorganic montmorillonite with 3 parts of organically modified montmorillonite A. The oxygen permeability test results are shown in Table 1.

Embodiment 3

[0039] Other conditions are the same as in Example 1, but 3 parts of organically modified montmorillonite B is used instead of inorganic montmorillonite, and no compatibilizer is added. The oxygen permeability test results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com