Hardenable siloxane resin composition for light emitting diode element

A technology of curable siloxane and resin composition, applied in electrical components, semiconductor devices, circuits, etc., can solve problems such as cracking, hardening, and easy deterioration, and achieve excellent thermal shock resistance due to temperature difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

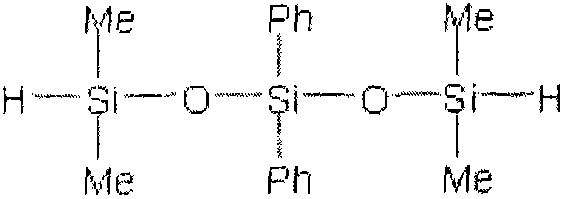

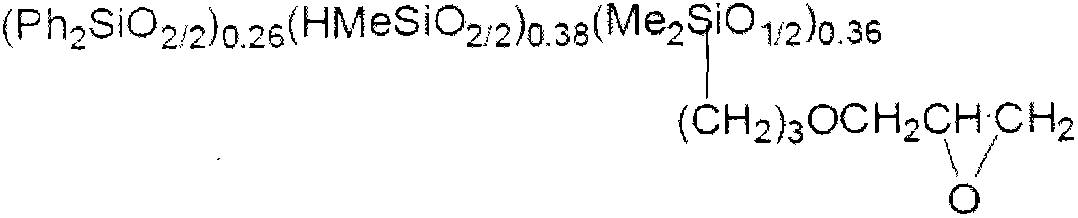

Method used

Image

Examples

Embodiment 1

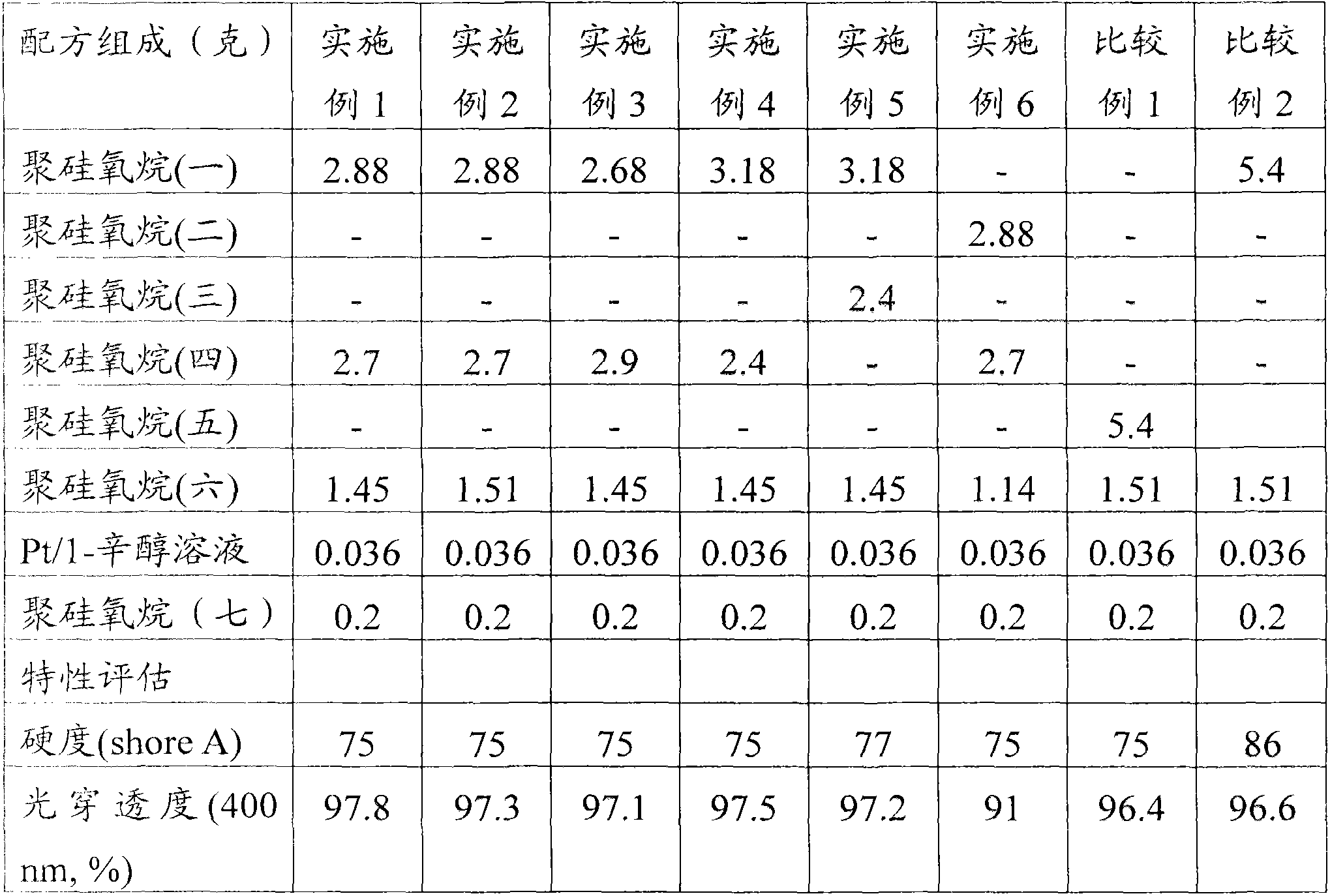

[0118] Take 2.88 grams of polysiloxane (1) and 2.7 grams of polysiloxane (4), and mix them uniformly at 90°C to form a mixture; after that, lower the temperature to room temperature, and then add 1.45 grams of polysiloxane ( Six), to obtain a reaction mixture; add 0.036 gram of Pt / 1-octanol solution (concentration is 5000ppm) in this reaction mixture as the catalyst of addition reaction, and add 0.2 gram of polysiloxane (7), through fully After mixing, vacuum defoaming is carried out to obtain the encapsulant formula.

Embodiment 2 to 6

[0120] The composition weight (grams) of the formula shown in Table 1, respectively take alkenyl-containing high cross-linking degree network polysiloxane and alkenyl-containing low cross-linking network polysiloxane, mix at 90 ° C Uniformly, to form a mixture; After that, the temperature is lowered to room temperature, and polysiloxane (6) is added to obtain a reaction mixture; 0.036 gram of Pt / 1-octanol solution (concentration of 5000ppm) and 0.2 gram of polysiloxane (7), and vacuum defoaming after thorough mixing, to prepare the encapsulation formulations of Examples 2 to 6.

[0121] The encapsulation glue formulations prepared in the above-mentioned Examples 1 to 6 were made into sheet test samples, and the hardness, light penetration, red ink test, reflow test, high temperature and high temperature were carried out on each sample according to the above-mentioned characteristic evaluation method Table 1 shows the evaluation results of the hot and cold cycle test (0°C / 260°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com