Adhesive composition, optical member, surface protective film, and adhesive sheet

A surface protection film, optical element technology, applied in the direction of optical elements, non-polymer adhesive additives, adhesive types, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0157] The present invention will be illustrated with reference to the following Examples and Comparative Examples. However, it is to be understood that the present invention is not limited to the illustrated embodiments and may be implemented in various ways.

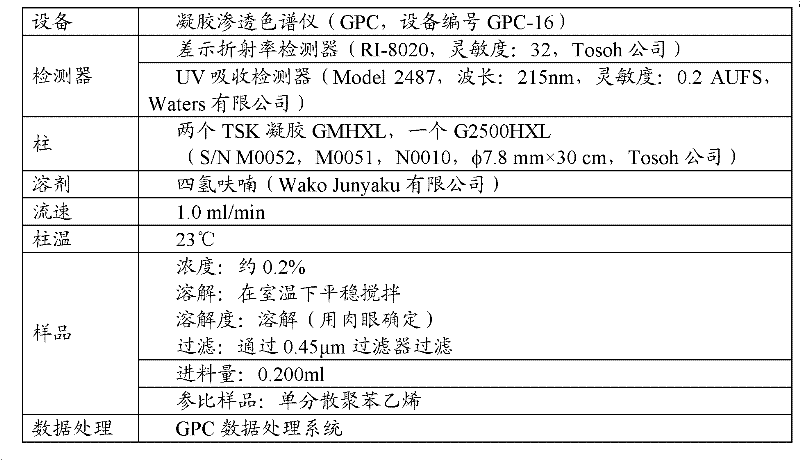

[0158] In the following examples, the solid content and viscosity of the polymer solution, the viscosity of the adhesive composition, and the weight average molecular weight of the polymer (A) were determined by the following methods.

[0159]

[0160] Accurately weigh approximately 1 g of polymer solution on a precisely weighed glass plate. The solution was dried at 105° C. for 1 hour and cooled to room temperature, after which the total weight of the glass plate and residual solids content was accurately weighed. The weight of the glass plate was defined as X, the total weight of the glass plate and polymer solution before drying was defined as Y, and the total weight of the glass plate and the remaining solid con...

preparation example 1

[0170] Put 99 parts by weight of n-butyl acrylate (Nihon Shokubai Co., Ltd.), 1 part by weight of 2-hydroxyethyl acrylate (Nihon Shokubai Co., Ltd.) and 120 parts by weight of ethyl acetate into a reflux condenser and stir in a flask and heated to 65 °C under a nitrogen atmosphere. 0.04 parts by weight of azobisisobutyronitrile (AIBN) was added, followed by polymerization for 6 hours while maintaining the mixture at 65°C. After the polymerization was completed, the mixture was diluted with 280 parts by weight of ethyl acetate to obtain a solution of polymer (A-1). The solution of polymer (A-1) had a solid content of 20% and a viscosity of 4500 mPa·s. In addition, polymer (A-1) had a weight average molecular weight of 1,600,000 g / mol.

preparation example 2 to 19

[0172] Solutions of polymers (A-2) to (A-19) were prepared in the same manner as in Preparation Example 1, except that the respective monomers were mixed according to the composition listed in Table 1. Subsequently, the solid content and viscosity of the solutions of the polymers (A-2) to (A-19), and the weight average molecular weights of the polymers (A-2) to (A-19) were measured, and the results are shown in Table 2. In Table 2, "BA", "MA", "HEA", "4HBA", "HEAA" and "AA" refer to butyl acrylate, methyl acrylate, 2-hydroxyethyl acrylate, 4- -Hydroxybutyl ester, N-2-hydroxyethylacrylamide and acrylic acid.

[0173] Table 2

[0174]

[0175] *M: Mega

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Weight average molecular weight | aaaaa | aaaaa |

| Weight average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com