Manufacturing method for semiconductor device

A manufacturing method and semiconductor technology, applied in the direction of semiconductor/solid-state device manufacturing, electrical components, circuits, etc., to achieve the effect of improving HCI effect, low cost, and improving interface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

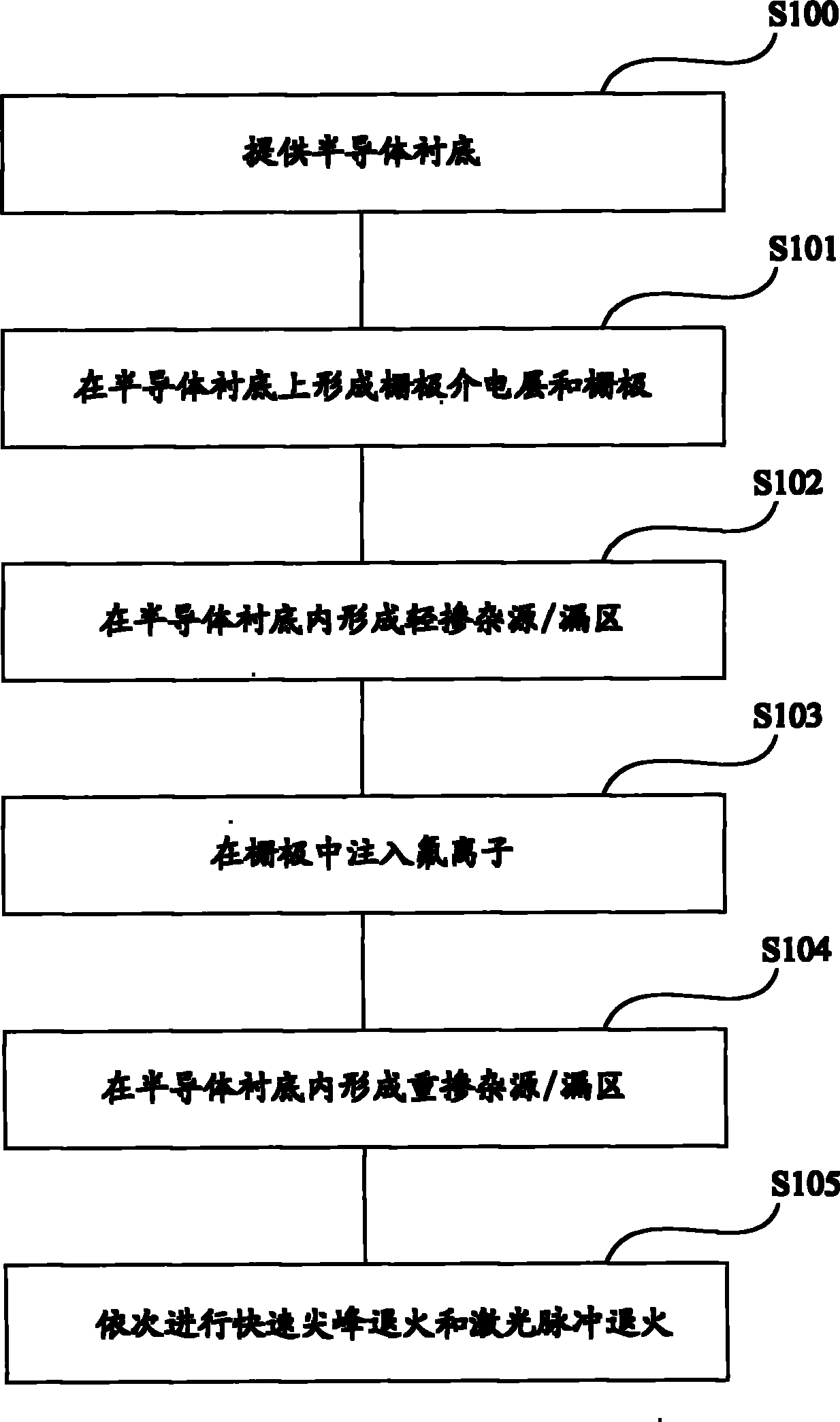

[0032] Such as figure 1 As shown, the manufacturing method of the semiconductor device in this embodiment includes the following steps:

[0033] S100, providing a semiconductor substrate;

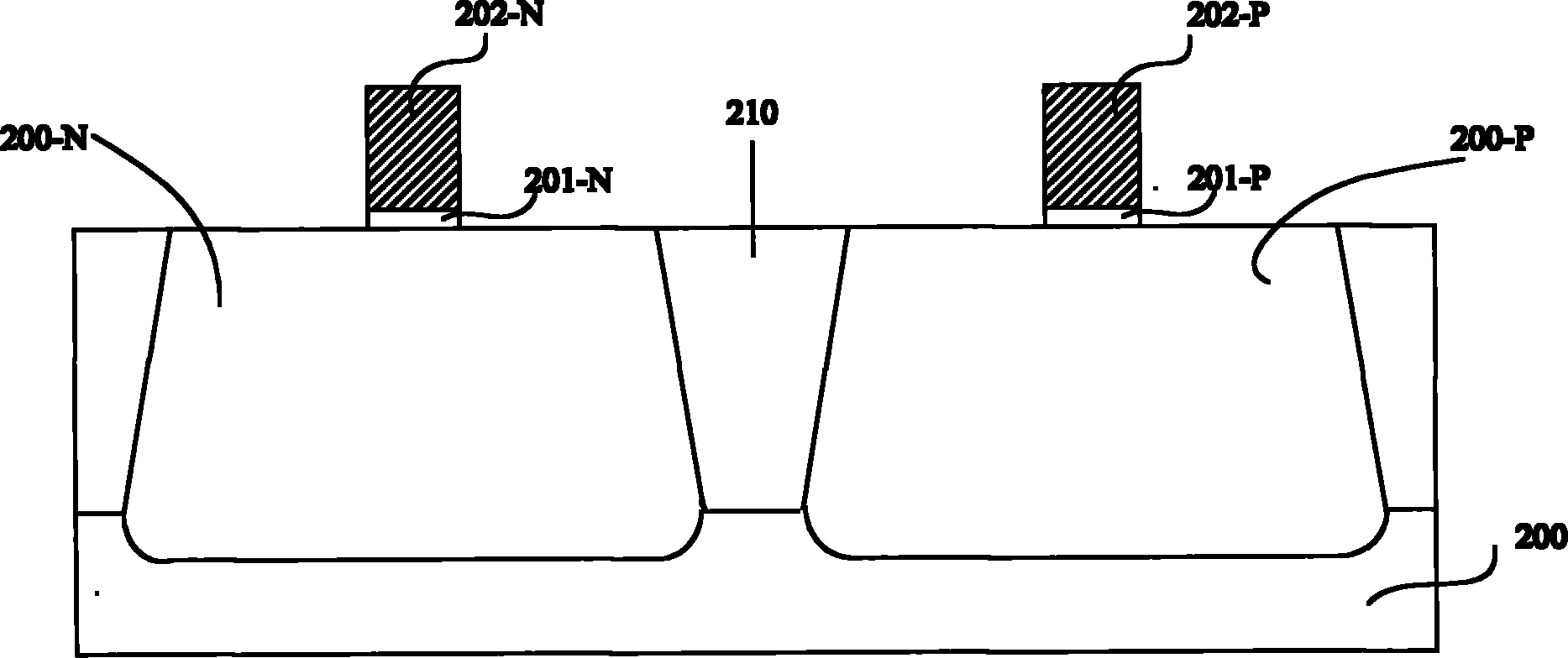

[0034] S101, forming a gate dielectric layer and a gate on the gate dielectric layer on the semiconductor substrate;

[0035] S102, performing lightly doped ion implantation in the semiconductor substrate on both sides of the gate to form lightly doped source / drain regions;

[0036] S103, implanting fluorine ions into the gate;

[0037] S104, performing heavily doped ion implantation in the semiconductor substrate on both sides of the gate to form heavily doped source / drain regions;

[0038] S105, performing rapid spike annealing and laser pulse annealing in sequence.

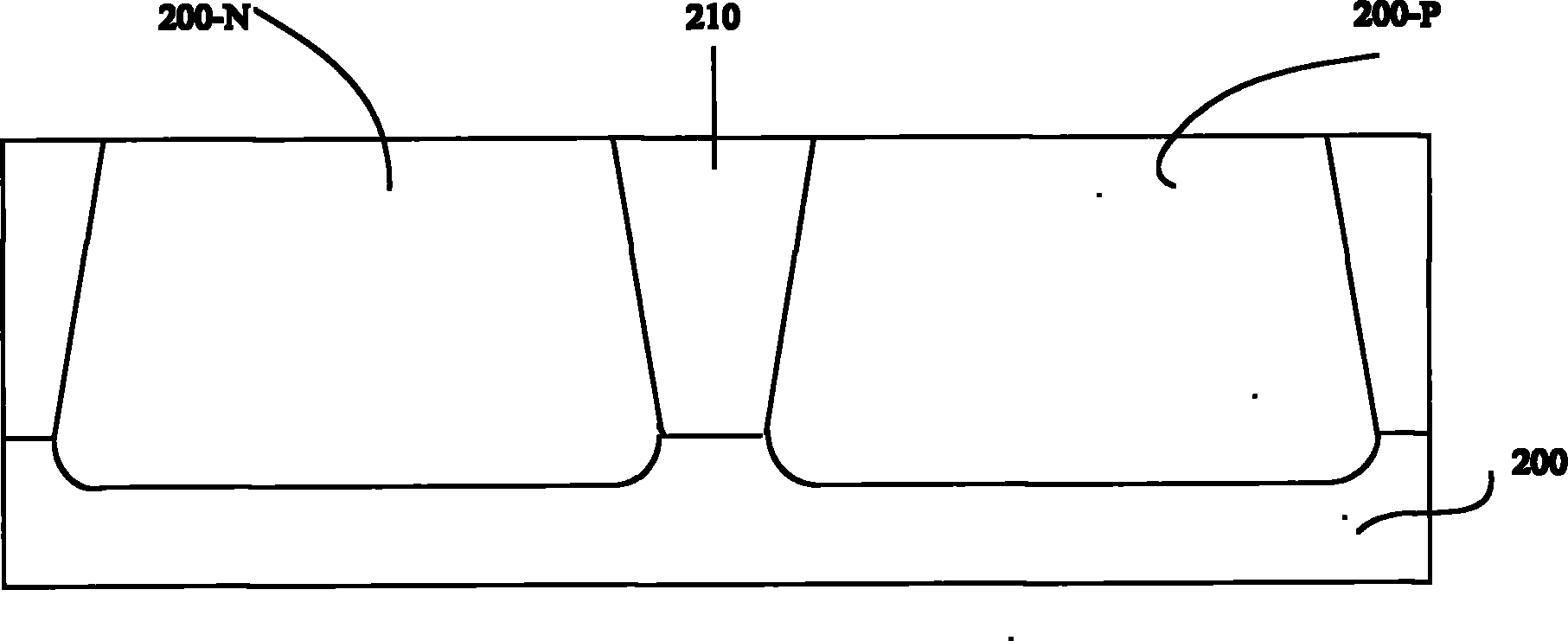

[0039] refer to figure 2 , first execute step S100 to provide a semiconductor substrate 200 . Wherein, the semiconductor substrate 200 includes: an N-type doped well 200 -N, a P-type doped well 200 -P and an isolation...

Embodiment 2

[0060] Such as Figure 10 As shown, the manufacturing method of the semiconductor device in this embodiment includes the following steps:

[0061]S300, providing a semiconductor substrate;

[0062] S301, forming a gate dielectric layer and a gate on the gate dielectric layer on the semiconductor substrate;

[0063] S302, performing lightly doped ion implantation in the semiconductor substrate on both sides of the gate to form lightly doped source / drain regions;

[0064] S303, performing heavily doped ion implantation in the semiconductor substrate on both sides of the gate to form heavily doped source / drain regions;

[0065] S304, implanting fluorine ions into the gate;

[0066] S305, performing rapid spike annealing and laser pulse annealing in sequence.

[0067] The difference between this embodiment and Embodiment 1 lies in the steps of "implanting heavily doped ions into the semiconductor substrate on both sides of the gate to form heavily doped source / drain regions" a...

Embodiment 3

[0070] Such as Figure 11 As shown, the manufacturing method of the semiconductor device in this embodiment includes the following steps:

[0071] S400, providing a semiconductor substrate;

[0072] S401, forming a gate dielectric layer and a gate on the gate dielectric layer on the semiconductor substrate;

[0073] S402, implanting fluorine ions into the gate;

[0074] S403, performing lightly doped ion implantation in the semiconductor substrate on both sides of the gate to form lightly doped source / drain regions;

[0075] S404, performing heavily doped ion implantation in the semiconductor substrate on both sides of the gate to form heavily doped source / drain regions;

[0076] S405, performing rapid spike annealing and laser pulse annealing in sequence.

[0077] The difference between this embodiment and Embodiment 1 is only in the steps of "implanting lightly doped ions into the semiconductor substrate on both sides of the gate to form lightly doped source / drain region...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com