Surface treatment agent and zinc-plating material

A technology of surface treatment agent and raw material, applied in the direction of metal material coating process, etc., can solve the problems of decreased corrosion resistance of the film layer, non-compliance with environmental protection requirements, etc., and achieve the effect of excellent corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

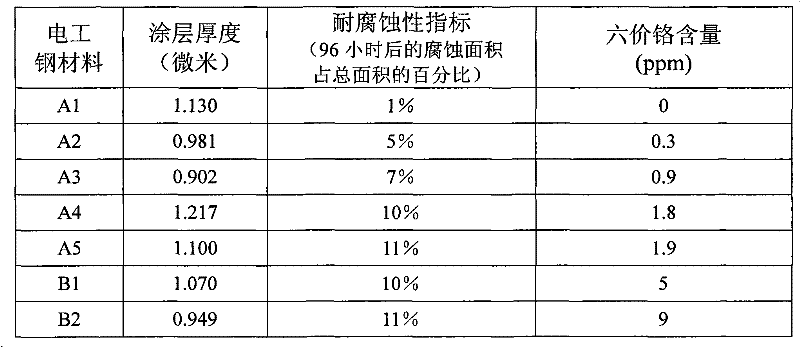

Embodiment 1

[0045] This embodiment is used to illustrate the surface treatment agent and galvanized material provided by the present invention.

[0046] With 50 grams of styrene-acrylic emulsion (purchased from Guangzhou Chaolong Chemical Technology Co., Ltd., the brand is xy-108b styrene-acrylic emulsion, solid content is 48% by weight, viscosity is 500-1000mPa·s), 40 grams of fluorocarbon emulsion (purchased From Beijing Shouchuang Nano Technology Co., Ltd., the brand is SKFT-I water-based fluorocarbon emulsion, solid content is 45% by weight, viscosity is 500-1000mPa s), 2 grams of trivalent chromium hydroxide, 120 grams of aluminum dihydrogen phosphate and 5 grams of boric acid were added to 500ml of water to dissolve, then added water to 1L, and mixed uniformly at 25°C to obtain surface treatment agent A1.

[0047] Apply 0.2 grams of the above-mentioned surface treatment agent A1 to the surface of a galvanized steel sheet (Panzhihua Steel and Vanadium Co., Ltd. of Panzhihua Iron and ...

Embodiment 2

[0049] This embodiment is used to illustrate the surface treatment agent and galvanized material provided by the present invention.

[0050] With 60 grams of styrene-acrylic emulsion (purchased from Guangzhou Chaolong Chemical Technology Co., Ltd., the brand is xy-108b styrene-acrylic emulsion, solid content is 48% by weight, viscosity is 500-1000mPa·s), 20 grams of fluorocarbon emulsion (purchased From Beijing Shouchuang Nano Technology Co., Ltd., the brand is SKFT-I water-based fluorocarbon emulsion, the solid content is 45% by weight, the viscosity is 500-1000mPa s), 1 gram of trivalent chromium hydroxide, 100 grams of aluminum dihydrogen phosphate and 3 grams of boric acid were added to 500ml of water to dissolve, then added water to 1L, and mixed uniformly at 25°C to obtain surface treatment agent A2.

[0051] Apply 1 gram of the above-mentioned surface treatment agent A2 to the surface of a galvanized steel sheet (Panzhihua Steel Vanadium Co., Ltd. of Panzhihua Iron and ...

Embodiment 3

[0053] This embodiment is used to illustrate the surface treatment agent and galvanized material provided by the present invention.

[0054] With 20 grams of styrene-acrylic emulsion (purchased from Guangzhou Chaolong Chemical Technology Co., Ltd., the brand is xy-108b styrene-acrylic emulsion, solid content is 48% by weight, viscosity is 500-1000mPa·s), 60 grams of fluorocarbon emulsion (purchased From Beijing Shouchuang Nano Technology Co., Ltd., the brand is SKFT-I water-based fluorocarbon emulsion, solid content is 45% by weight, viscosity is 500-1000mPa s), 3 grams of trivalent chromium hydroxide, 80 grams of aluminum dihydrogen phosphate Add 1 gram of boric acid to 500ml of water to dissolve, add water to 1L, and mix well at 25°C to obtain surface treatment agent A3.

[0055] Apply 1.5 grams of the above-mentioned surface treatment agent A3 to the surface of a galvanized steel sheet (Panzhihua Steel and Vanadium Co., Ltd. of Panzhihua Iron and Steel Group Co., Ltd., mode...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com