Optical fiber sensing technology-based operating rod

An optical fiber sensing technology and joystick technology, which is applied in the field of joysticks based on optical fiber sensing technology, can solve problems such as limitations, and achieve the effects of low cost, good use effect, and easy processing and production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

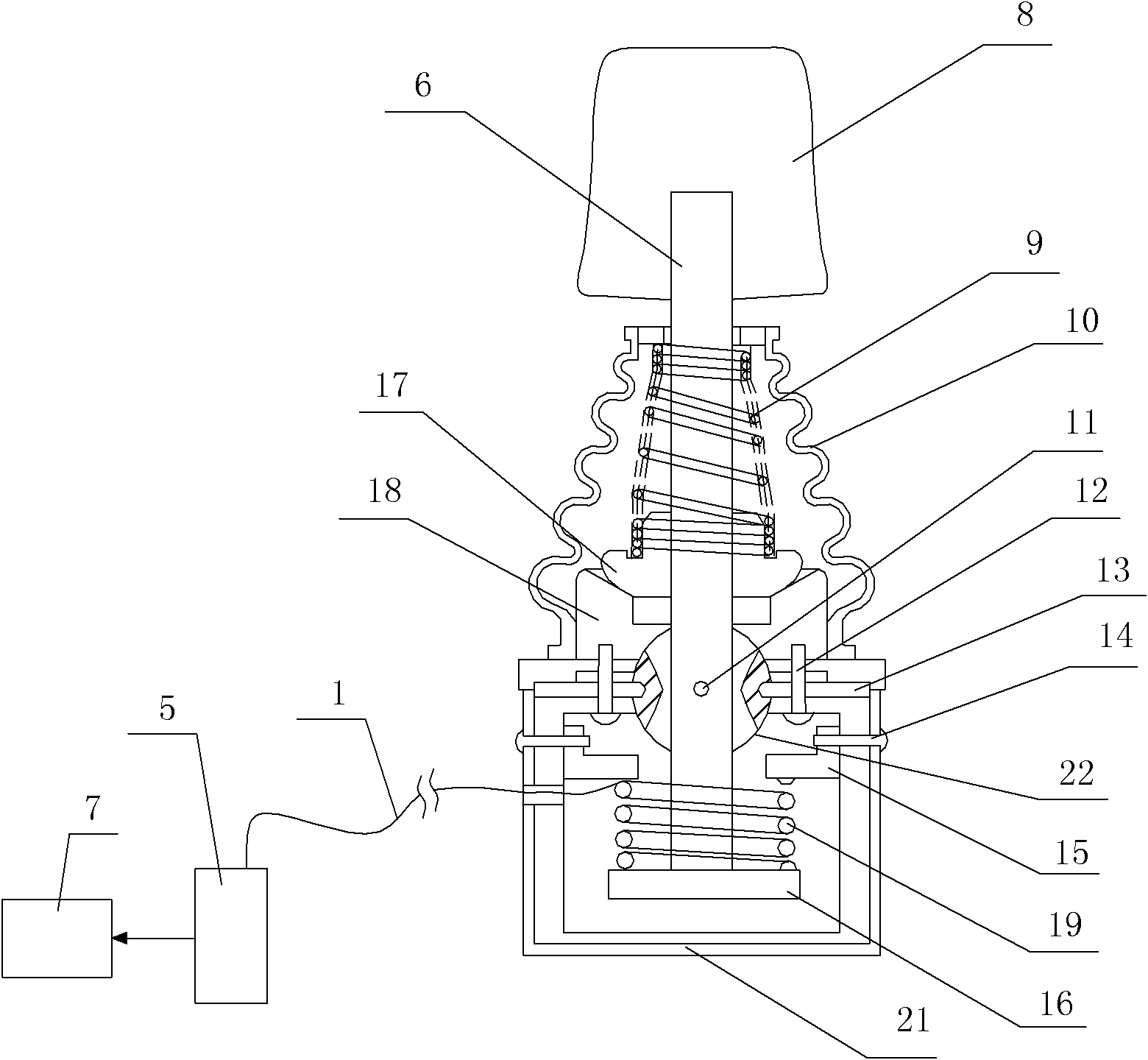

[0040] Such as figure 1 , figure 2 , image 3 and Figure 4 The shown joystick based on optical fiber sensing technology includes a joystick body 6, a base 18, a rotating shaft 22, a spring one 9 and a spring base 17, and the spring one 9 is sleeved on the joystick body 6, so The joystick body 6 is provided with a handle 8, and the spring base 17 is arranged under the spring one 9 to carry the spring one 9. The preferred method is that the spring one 9 is covered with a dust cover 10; The seat 18 is located below the spring base 17, the rotating shaft 22 is arranged on the base 18, and the rotating shaft 22 is arranged on the described base 18 through the first positioning pin 11 and the second positioning pin 13, preferably The method is that the first locating pin 11 and the second locating pin 13 are fixed on the base 18 by screws 12, the rotating shaft 22 is provided with an opening communicating up and down, and the joystick body 6 can extend out from the opening of t...

Embodiment 2

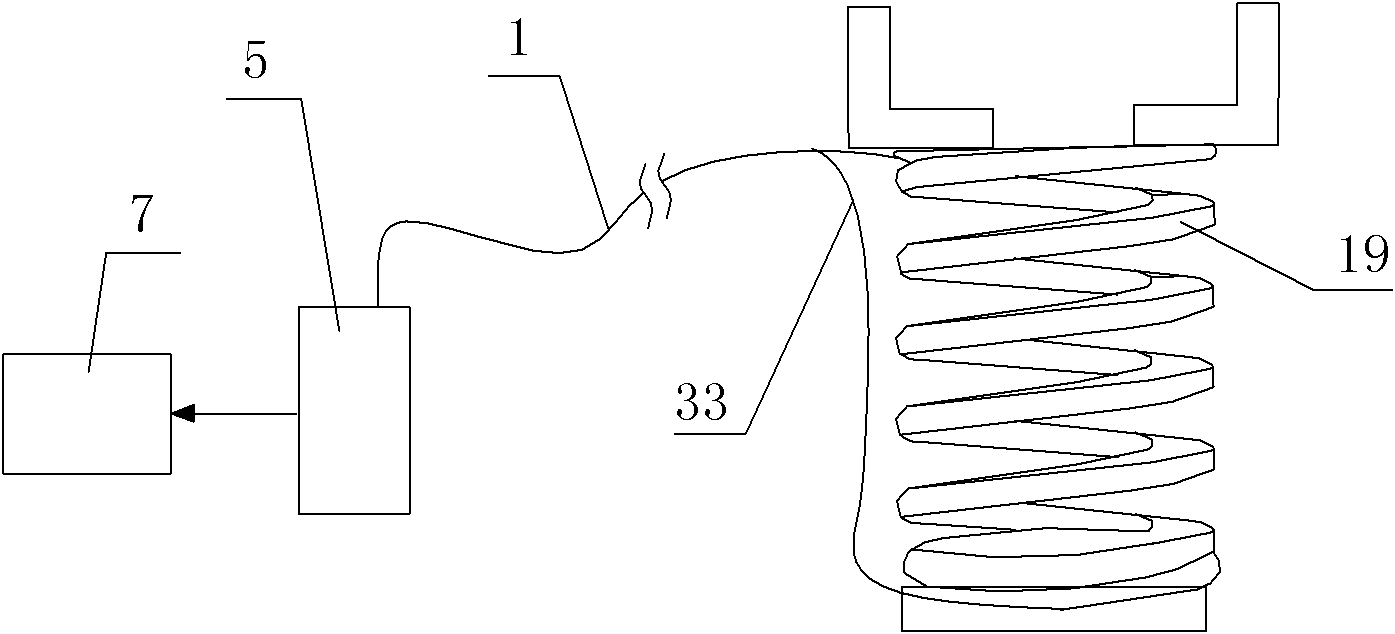

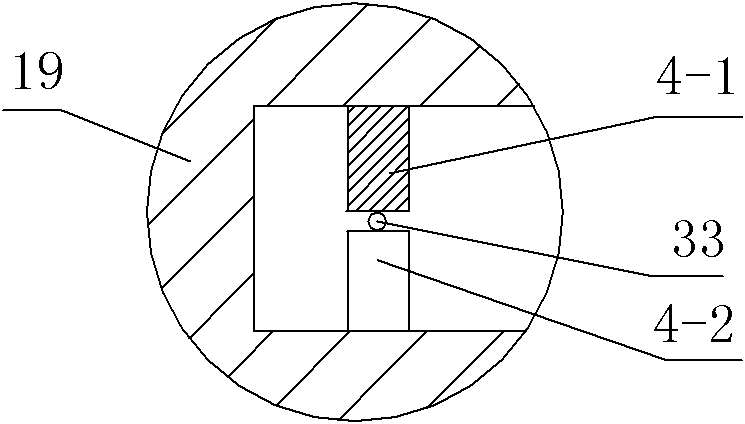

[0046] Such as Figure 5 , Figure 6 As shown, in this embodiment, the difference from Embodiment 1 is that the curved support is a spring 2 38, and the first A-side deformed tooth 4-1 and the first B-side deformed tooth 4-2 are correspondingly arranged on the spring 2 38, between two adjacent coils of spring wire, and the first A-side deformed teeth 4-1 and the first B-side deformed teeth 4-2 are alternately arranged. The preferred method is that the second A side deformation teeth 4-3 and the second B side deformation teeth 4-4 are also arranged on the spring two 38, and the second A side deformation teeth 4-3 and the second B side deformation teeth 4-4 4 are arranged alternately, and the second signal optical fiber 35 is clamped between the deformation teeth on both sides of the second A and B sides. The second A side deformation teeth 4-3 and the second B side deformation teeth 4-4 are along the spring Every 360 degrees of the curved support formed by two 38 is a cycle, ...

Embodiment 3

[0048] Such as Figure 7 , Figure 8 As shown, in this embodiment, the difference from Embodiment 1 is that the curved support is a bellows 40, and the first A-side deformation teeth 4-1 and the first B-side deformation teeth 4-2 are correspondingly arranged on the bellows On the two opposite sides of the recess on the pipe wall 42 of 40, the first A-side deforming teeth 4-1 and the first B-side deforming teeth 4-2 are alternately arranged. The preferred method is that the second A-side deformation teeth 4-3 and the second B-side deformation teeth 4-4 are also arranged on the pipe wall 42, and the second A-side deformation teeth 4-3 and the second B-side deformation teeth 4- 4 are arranged alternately, and the second signal optical fiber 35 is clamped between the deformation teeth on both sides of the second A and B sides, and the second deformation teeth 4-3 on the A side and the second deformation teeth 4-4 on the B side are along the Every 360 degrees of the tube 40 is a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com