Selenium-rich feed for cultivating selenium-rich fish and preparation method and application thereof

A selenium-enriched and feed technology, applied in the application, animal feed, animal feed and other directions, can solve the problems of high toxicity risk, detection of selenium content in fish, not involving selenium-enriched fish breeding methods and selenium-enriched feed, etc., to improve selenium Lack of status, highlighting substantive features, and achieving the effect of transformation and enrichment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

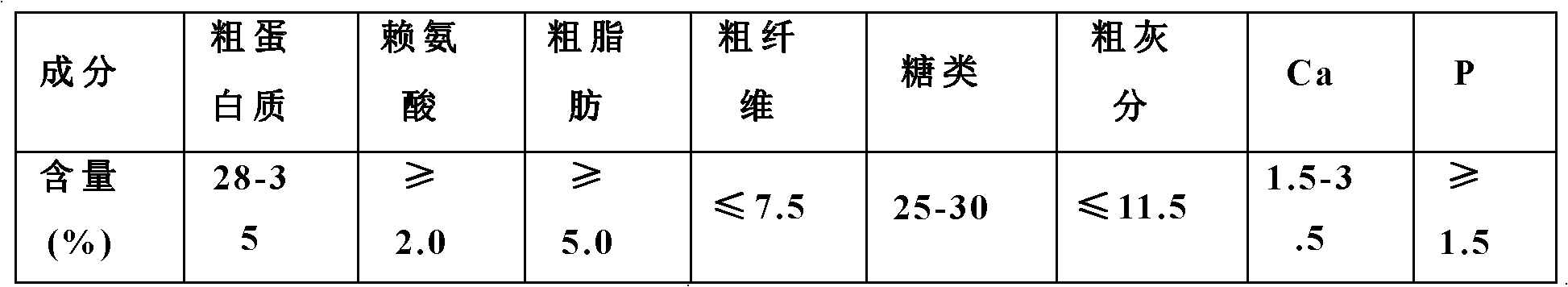

[0068] In a freshwater fish breeding base, selenium-enriched fish feed was started to be fed 90 days after the fry were released. The fish feed consists of the following:

[0069] (1) Select the above-mentioned selenium-enriched corn flour, selenium-enriched broccoli powder, selenium-enriched soybean meal, imported fish meal, chicken meal, cuttlefish viscera powder, rapeseed meal, and 57% soybean meal after cleaning impurities and removing iron, respectively pulverized and passed through the diameter It is a 2 mm sieve and has been ultrafinely pulverized (the particle size is guaranteed to pass through a 100 mesh sieve);

[0070] (2) Take 5 parts of the crushed selenium-enriched corn flour, 5 parts of selenium-enriched broccoli powder, 5 parts of selenium-enriched soybean meal, 25 parts of imported fish meal, 16 parts of chicken meal, 2 parts of squid viscera powder, and 12 parts of rapeseed meal , 11 parts of 57% soybean meal;

[0071] (3) Take 3 parts of the above-mentione...

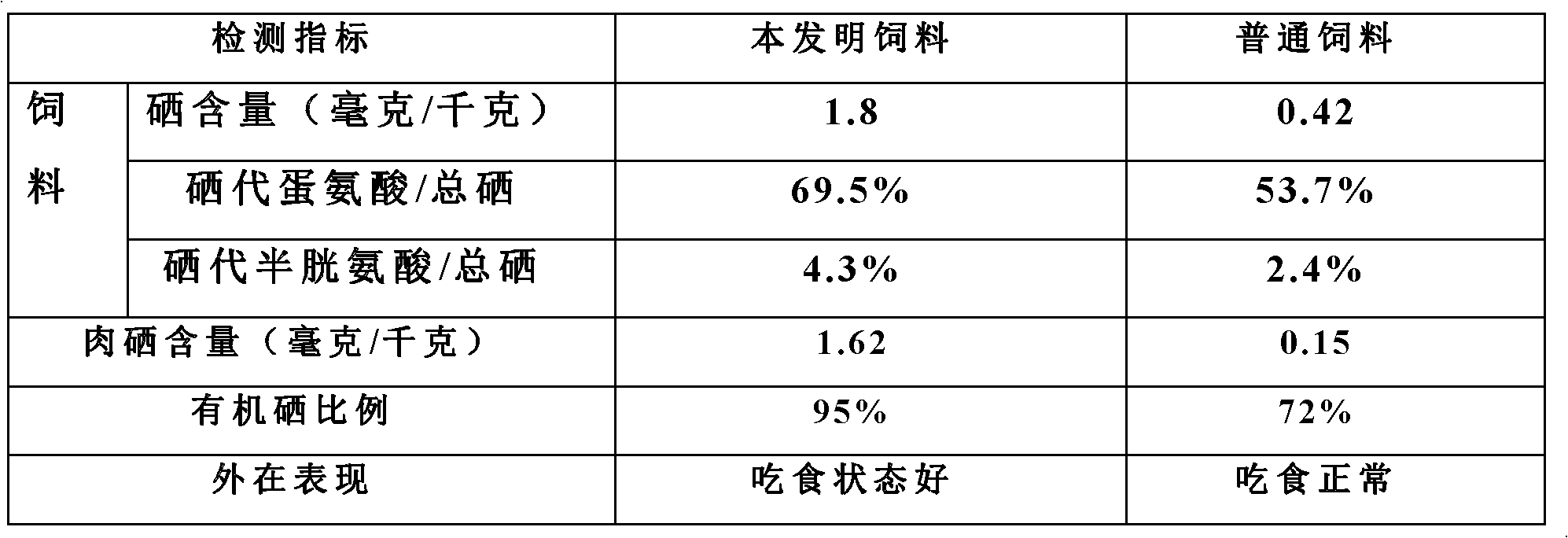

Embodiment 2

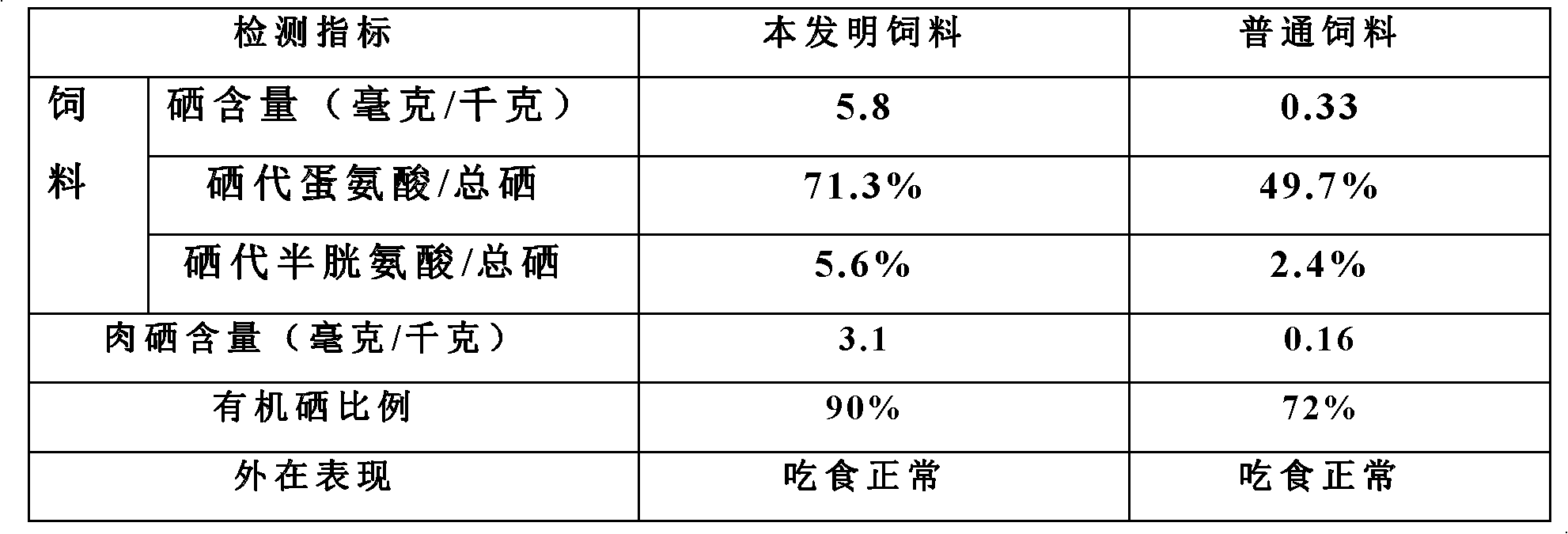

[0079] The raw materials and processing method are the same as in Example 1, and the weight ratio of each component is: 6 parts of selenium-enriched corn flour, 8 parts of selenium-enriched broccoli powder, 7 parts of selenium-enriched soybean meal, 24 parts of imported fish meal, and 17 parts of chicken meal , 2 parts of squid offal powder, 9 parts of rapeseed meal, 9 parts of 57% soybean meal, 3 parts of molasses yeast, 4 parts of full-fat soybean powder, 3 parts of soybean lecithin, 0.3 part of multidimensional compound, 0.7 part of compound mineral salt, dihydrogen phosphate 3 parts of calcium, 0.6 part of choline chloride, 1.4 parts of allicin, 2 parts of refined fish oil, the feed preparation method is the same as embodiment 1, the selenium content in the feed is 5.8 mg / kg, and the ratio of selenomethionine to total selenium is 71.3%. Selenocysteine accounts for 5.6% of the total selenium.

[0080] Feeding the feed of the present invention and common feed to the fish m...

Embodiment 3

[0085] The raw materials and processing method are the same as in Example 1, and the weight ratio of each component is: 9 parts of selenium-enriched corn flour, 10 parts of selenium-enriched broccoli powder, 8 parts of selenium-enriched soybean meal, 23 parts of imported fish meal, and 15 parts of chicken meal , 2 parts of squid offal powder, 8 parts of rapeseed meal, 8 parts of 57% soybean meal, 3 parts of molasses yeast, 4 parts of full-fat soybean powder, 3 parts of soybean lecithin, 0.3 part of multidimensional compound, 0.7 part of compound mineral salt, dihydrogen phosphate 3 parts of calcium, 0.6 part of choline chloride, 1.4 parts of allicin, 2 parts of refined fish oil, the feed preparation method is the same as embodiment 1, the selenium content in the feed is 9.7 mg / kg, and selenomethionine accounts for 72.6% of the total selenium ratio, Selenocysteine accounts for 6.3% of the total selenium.

[0086] Feeding the feed of the present invention and common feed to th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com