Method for preparing natural mutton flavour by utilizing sheep bone

A sheep bone and mutton technology, applied in food preparation, application, food science and other directions, can solve the problems of inability to effectively extract other nutrients and not suitable for industrialized production, and achieve the effect of full taste, vivid flavor and rich nutrition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

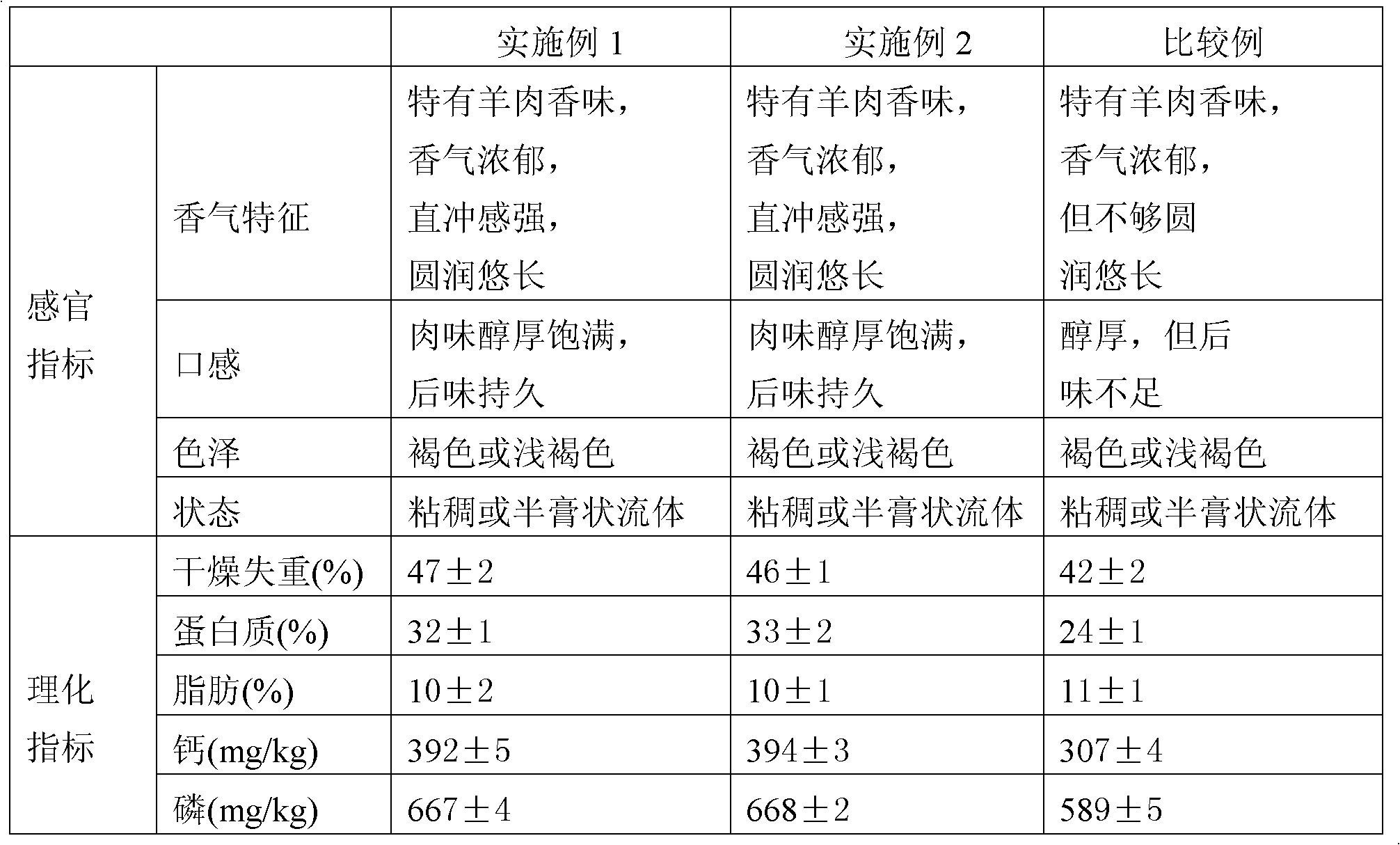

Examples

Embodiment 1

[0028] The cleaned sheep bones are decapitated, and the bones are put into a bone crusher to be crushed into bone grains with a diameter less than 0.5cm.

[0029] Weigh 300g of bone grains and put them in a 2L stainless steel reaction tank, wash them with clean water for 2-3 times and drain the blood, add 300g of clean water, seal them, put them in an autoclave, set the temperature at 130°C and time for 3 hours, after cooking is completed Filter out the bone residue with gauze, and separate the bone oil and bone broth with a separatory funnel. The separated bone broth also contains a small amount of fat, which is removed by a centrifuge (model BECKMAN COULTER Avanti J-E, centrifugal force 4400×g);

[0030] After adjusting the pH of bone broth to 7.1 with 1mol / L citric acid solution, detect the concentration of protein in bone broth, calculate the protein content in bone broth according to the volume of bone broth and the concentration of protein in bone broth, add flavor protea...

Embodiment 2

[0033] Remove the flesh from the washed sheep bones, put the bones into a bone grinder and crush them into bone particles with a diameter of less than 0.5cm, weigh 300g of bone particles in a 2L stainless steel reaction tank, wash them with clean water for 2-3 times and drain the blood. Add 450g of water, seal it, put it in an autoclave, keep the temperature at 125°C for 4 hours, filter out the bone residue with gauze after cooking, and separate the bone oil and bone broth with a separatory funnel. The separated bone broth also contains a small amount Fat is removed with a centrifuge (model is BECKMAN COULTER Avanti J-E, centrifugal force 4400×g);

[0034] Regulate the bone broth pH to 7.1 with 1mol / L citric acid solution, detect the concentration of protein in the bone broth, calculate the protein content in the bone broth according to the volume of the bone broth and the concentration of protein in the bone broth, add flavor protease (574LAPU / g activity unit) 30LAPU / g (that ...

Embodiment 3

[0037]Remove the flesh from the washed sheep bones, put the bones into a bone grinder and crush them into bone particles with a diameter of less than 0.5cm, weigh 300g of bone particles in a 2L stainless steel reaction tank, wash them with clean water for 2-3 times and drain the blood. Add 300g, seal, put clean water into the autoclave, keep the temperature at 130°C for 3 hours, filter out the bone residue with gauze after cooking, separate the bone oil and bone broth with a separatory funnel, and the separated bone broth also contains a small amount Fat is removed with a centrifuge (model is BECKMAN COULTER Avanti J-E, centrifugal force 4400×g);

[0038] Regulate the bone broth pH to 7.1 with 1mol / L citric acid solution, detect the concentration of protein in the bone broth, calculate the protein content in the bone broth according to the volume of the bone broth and the concentration of protein in the bone broth, add flavor protease (574LAPU / g activity unit) 35LAPU / g (that i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com