Amphoteric reaction-type surfactant and preparation method thereof

A surfactant, amphoteric reaction technology, used in the preparation of carboxylic acid amides, chemical instruments and methods, preparation of organic compounds, etc., can solve the problems of poor freeze-thaw stability of latex, reduced film water resistance, slow film formation rate, etc. , to achieve the effect of excellent emulsifying performance, reducing material loss and not easy to homopolymerize

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

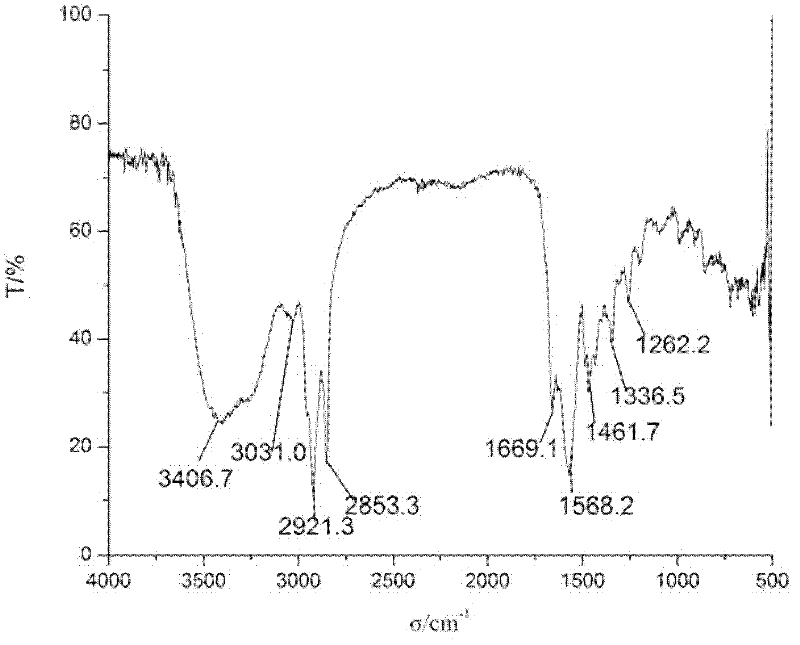

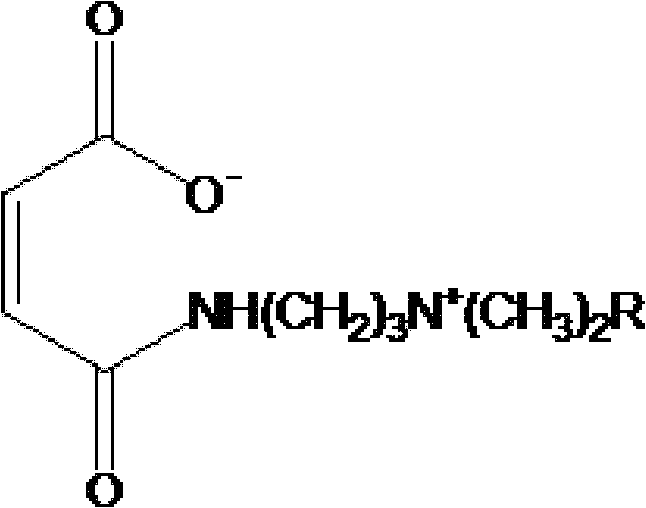

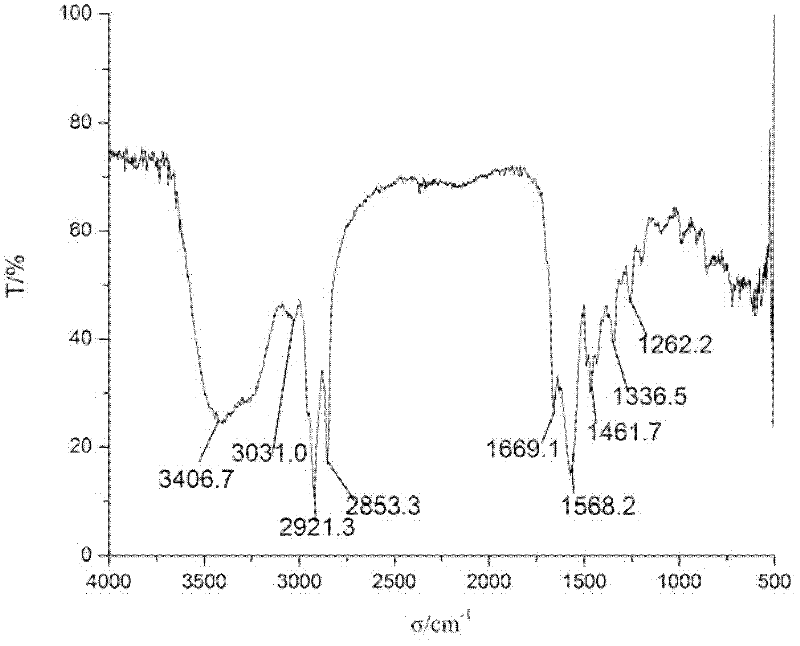

Image

Examples

Embodiment 1

[0024] (1) Preparation of intermediate: Take 10.2g (0.10mol) of N,N-dimethyl-1,3-propanediamine, dissolve it in 50mL of benzene, and transfer it to the dropping funnel. Take molar ratio n (N, N-dimethyl-1,3-propanediamine): n (maleic anhydride) is 1: 1 maleic anhydride, dissolved in 100mL of benzene, and then transferred to In a 250mL three-necked flask, install a stirrer, a thermometer, a dropping funnel, and heat in a water bath. The dropping temperature is 30°C, and the dropping time is 1h. , stand still, filter after cooling, wash the filter cake several times with ethyl acetate, and wash the product several times with ethyl acetate, after filtration, dry it under vacuum at 40°C overnight, calculate the yield, and the yield can reach 87.2%. Take an appropriate amount of product and measure the neutralization value to determine the amount of alkali required for neutralization in the next step.

[0025] (2) Preparation of amphoteric reactive surfactant: get 10.0g (0.05mol) ...

Embodiment 2

[0031] (1) Preparation of intermediates: take maleic anhydride and N,N-dimethyl-1,3-propanediamine in a molar ratio of 1.1:1 and dissolve them in toluene, wherein N,N-dimethyl-1 , 3-Propylenediamine is fed by dropwise addition, the dropwise addition temperature is about 25°C, and the dropwise addition time is 0.5h. , cooling and filtering to obtain a filter cake, wash the gained filter cake with ethyl acetate, filter and dry to obtain the product white powder, intermediate N-(3-dimethylaminopropyl) maleamic acid.

[0032] (2) Preparation of amphoteric reactive surfactant: take water to dissolve the intermediate N-(3-dimethylaminopropyl)maleamic acid, the mass ratio of water to the intermediate is 1.2:1, in the dissolved solution Add dropwise mass concentration of 15% sodium hydroxide or potassium hydroxide solution to adjust the pH value to 9; then add 1-bromodecane, the added 1-bromodecane: intermediate molar ratio is 1.0~1.1: 1, Then add isopropanol, so that the volume ratio ...

Embodiment 3

[0035] (1) Preparation of intermediate: take maleic anhydride and N,N-dimethyl-1,3-propanediamine in a molar ratio of 1.2:1 and dissolve them in xylene, wherein, N,N-dimethyl- 1,3-Propylenediamine is fed by dropwise addition, the dropwise addition temperature is about 35°C, and the dropwise addition time is 1.5h. After the dropwise addition is completed, the temperature is raised to 55°C, and the reaction is continued for 2 to 3h. After the reaction is completed, After standing, cooling and filtering, the filter cake was obtained, and the obtained filter cake was washed with ethyl acetate, filtered and dried to obtain the product white powder, intermediate N-(3-dimethylaminopropyl)maleamic acid;

[0036] (2) Preparation of amphoteric reactive surfactant: take water to dissolve the intermediate N-(3-dimethylaminopropyl)maleamic acid, the mass ratio of water to the intermediate is 1.5:1, in the dissolved solution Add dropwise mass concentration of 30% sodium hydroxide or potassi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com