Carbon-loaded pyridine-nitrogen-modified cobalt-phthalocyanine catalyst, and preparation method and application thereof

A technology of carbon-supported pyridine nitrogen and catalysts, which is applied in the direction of physical/chemical process catalysts, chemical instruments and methods, organic compounds/hydrides/coordination complex catalysts, etc. Complicated methods and other problems, to achieve the effect of improving electrode activity, low cost, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

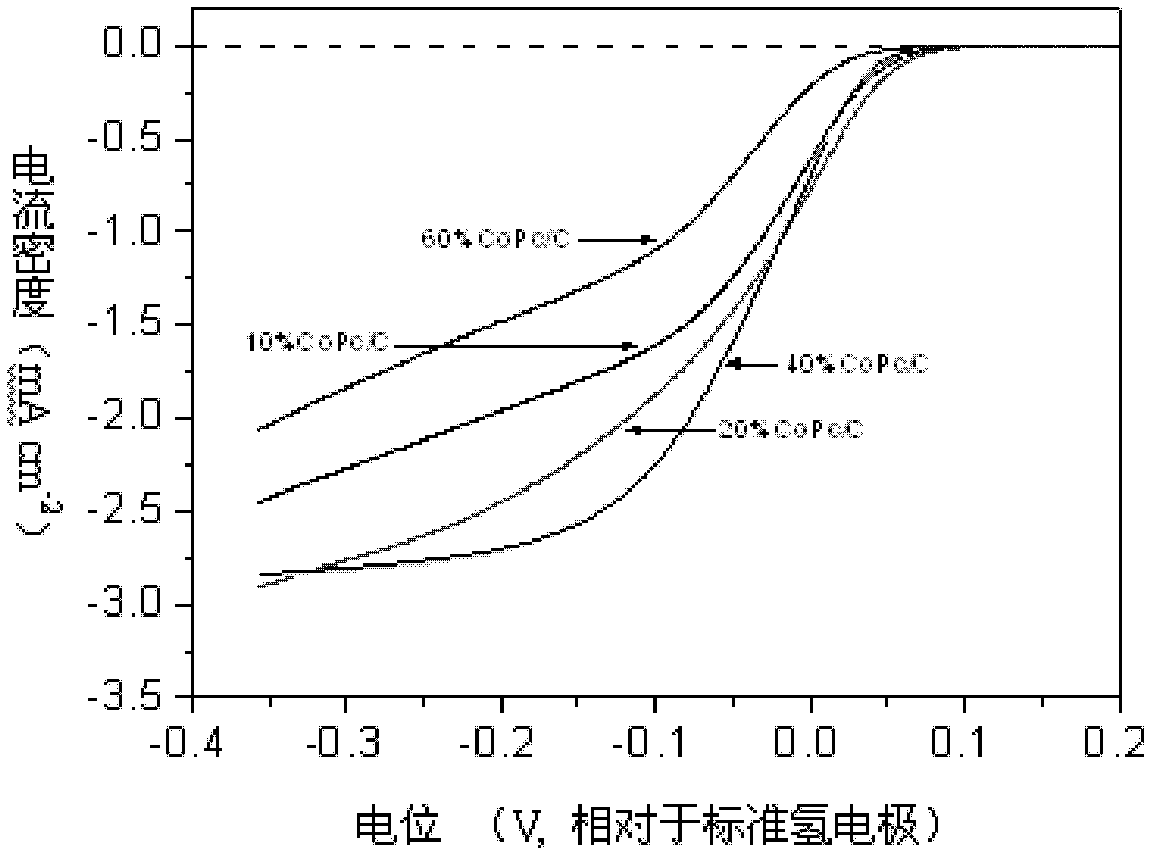

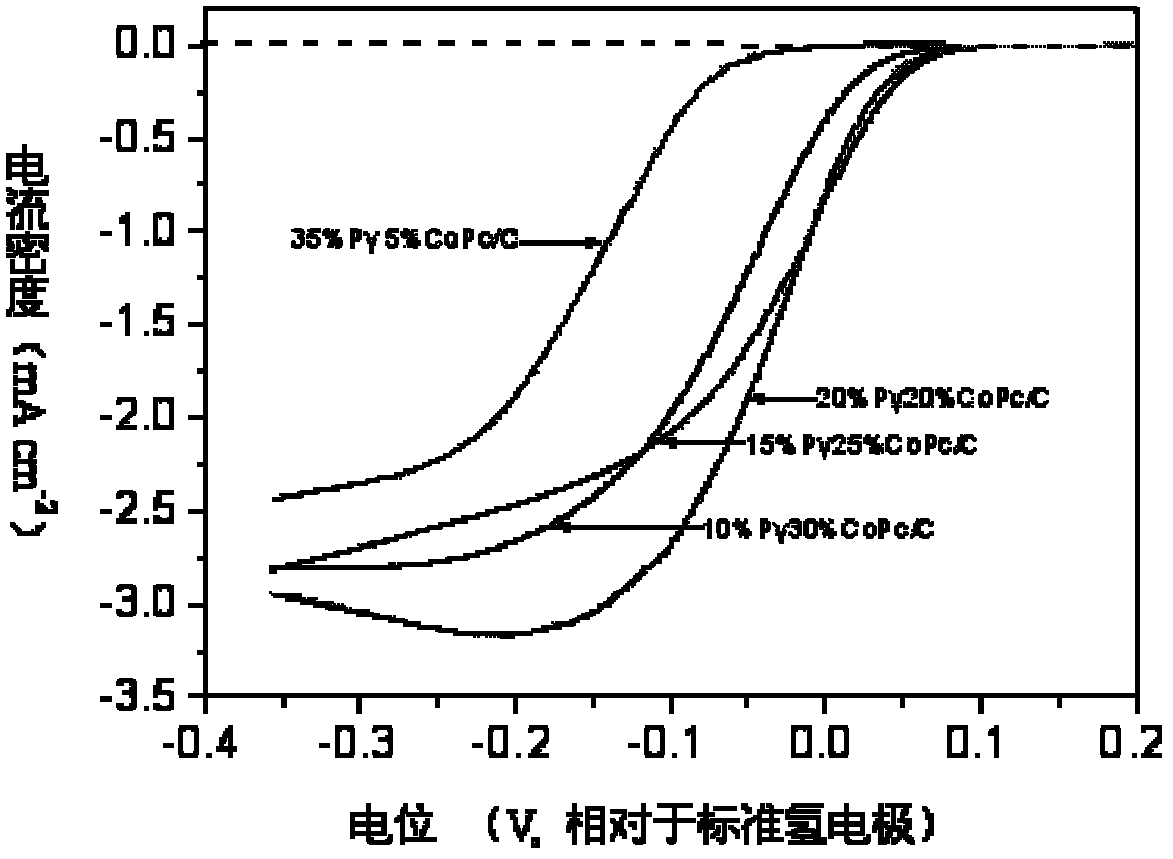

[0028] Preparation of 10%Py30%CoPc / C catalyst: Weigh 0.0300g cobalt phthalocyanine, 0.0100g pyridine and 0.0600g Vulcan XC-72R carbon powder and place them in an agate mortar. Then add 10ml of methanol of analytical grade and grind thoroughly until the methanol is completely volatilized. The agate mortar and the mixture contained therein were put into a vacuum oven at 40° C. for 1 h to be vacuum-dried to obtain the desired CoPc-Py / C catalyst, and the mass ratio of CoPc to Py was 3:1.

Embodiment 2

[0030] Preparation of 15%Py25%CoPc / C catalyst: Weigh 0.0250g cobalt phthalocyanine, 0.0150g pyridine and 0.0600g Vulcan XC-72R carbon powder and put them in an agate mortar. Then add 10ml of ethanol of analytical grade and grind thoroughly until the ethanol evaporates completely. The agate mortar and the mixture contained therein were put into a vacuum oven at 40° C. for 1 h to be vacuum-dried to obtain the desired CoPc-Py / C catalyst, and the mass ratio of CoPc to Py was 5:3.

Embodiment 3

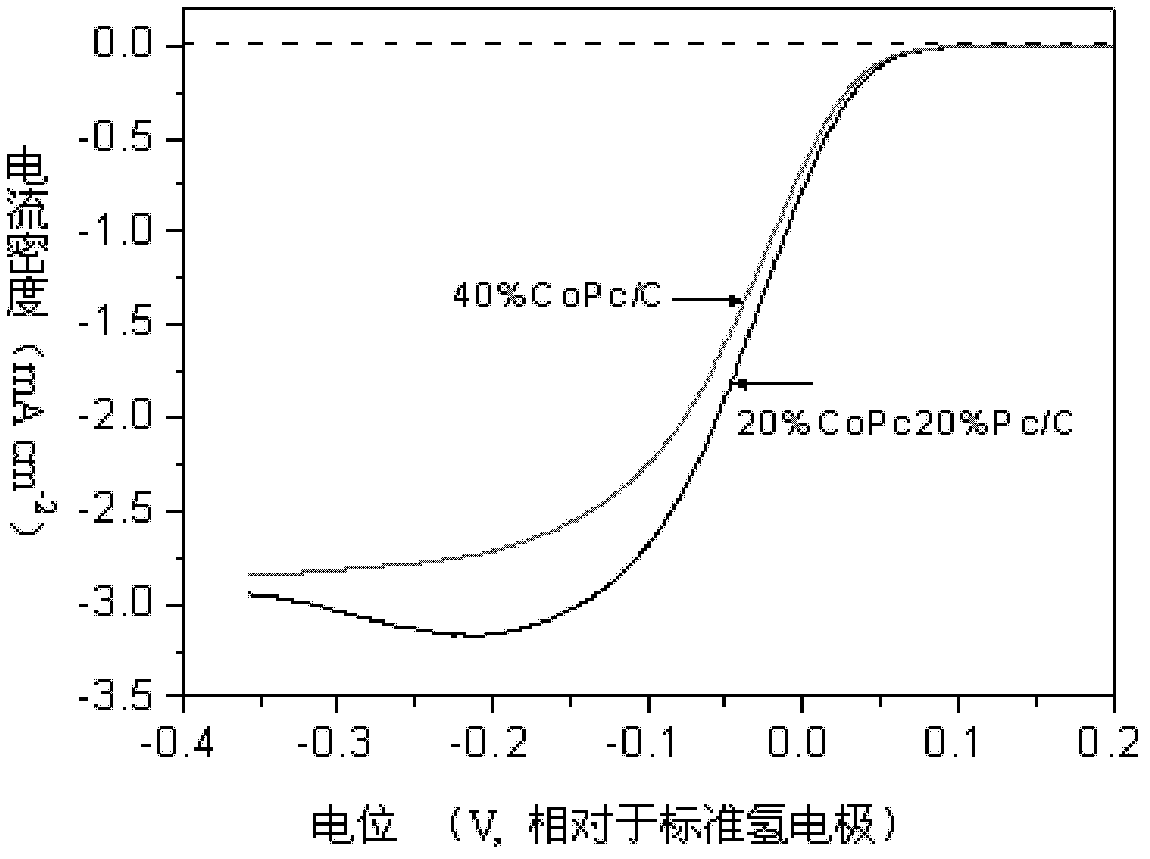

[0032] Preparation of 20%Py20%CoPc / C catalyst: 0.0200g cobalt phthalocyanine, 0.0200g pyridine and 0.0600g Vulcan XC-72R carbon powder were weighed and placed in an agate mortar. Then add 10ml of methanol of analytical grade and grind thoroughly until the methanol is completely volatilized. Put the agate mortar and the mixture inside into a vacuum oven at 40° C. for 1 h in vacuum to obtain the desired CoPc-Py / C catalyst, and the mass ratio of CoPc to Py is 1:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com