Electric drive dump truck

A technology for electric drive and dump trucks, which is applied in the direction of inclined load-carrying vehicles, etc. It can solve the problems of unstable engine operation characteristics, complex dump mechanism structure, and lack of versatility, so as to eliminate exhaust pollution, avoid adverse effects, The effect of saving driving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

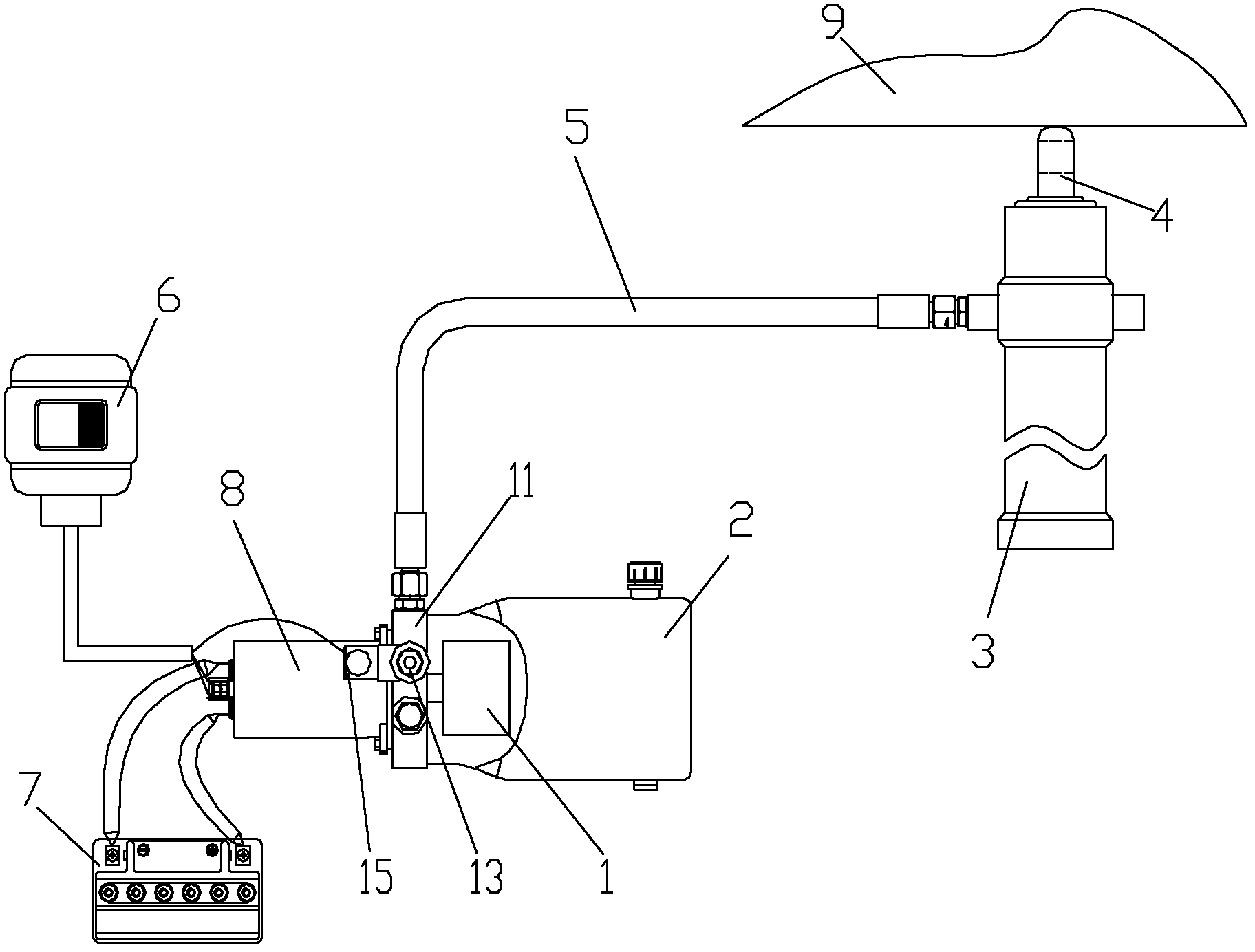

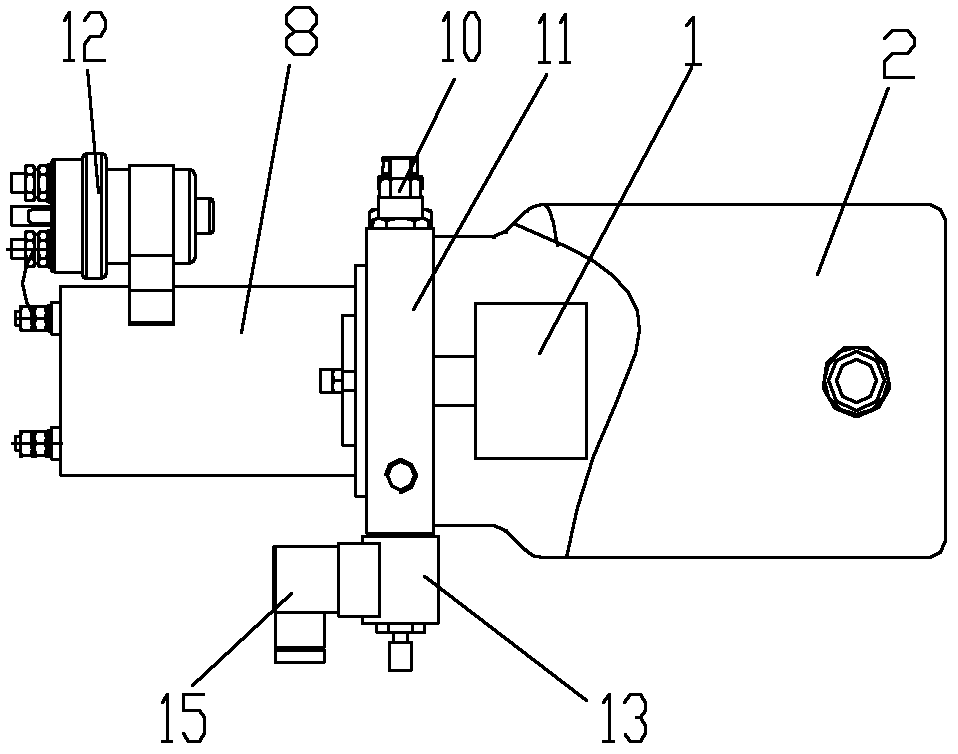

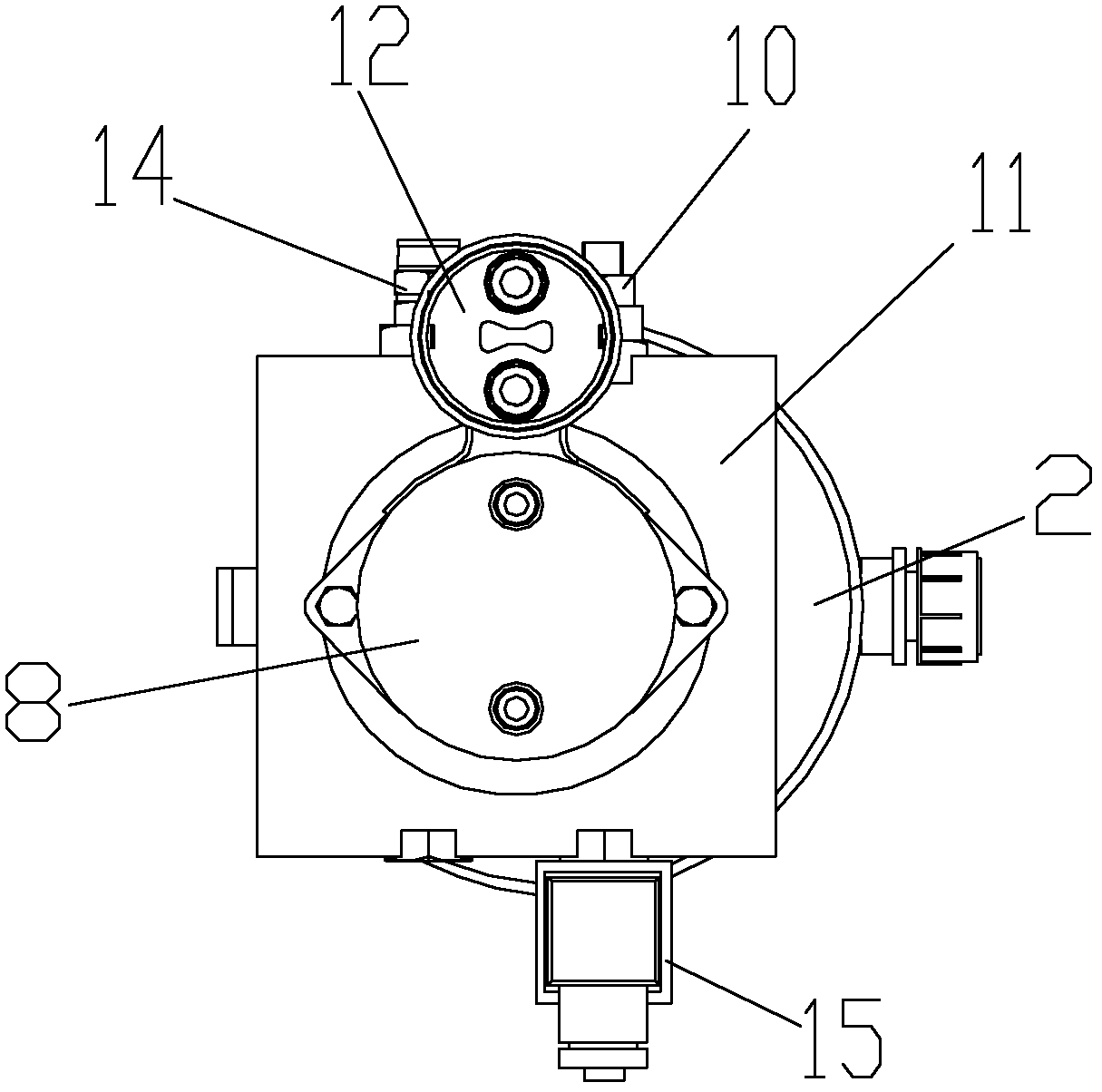

[0018] figure 1 is a schematic diagram of the structure of the present invention, figure 2 It is a schematic diagram of the structure of the driving device of the present invention, image 3 for figure 2 View along the A direction, as shown in the figure: the electric-driven dump truck of this embodiment includes a car body, a carriage 9 and a carriage drive system arranged on the car body. The hydraulic cylinder assembly that unloads the force and the driving device that provides driving energy to the hydraulic cylinder assembly, as shown in the figure, the hydraulic cylinder assembly includes the hydraulic cylinder block 3 and the piston rod used to support the dump truck compartment 4. The end of the piston rod 4 is supported on the casing 9 and used to drive its self-unloading; the outlet of the oil pump 1 is connected to the hydraulic cylinder 3 through necessary valve parts and pipelines, which belongs to the prior art and will not be repeated here; The driving devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com