Explosion suppression filling material with composite structure

A filling material and composite structure technology, applied in container filling methods, containers, bottles, etc., can solve problems such as failure of barrier and explosion-proof function, easy deformation and collapse, and easily broken debris, achieve uniform structural strength, reduce collapse and deformation. , to avoid the effect of deformation and collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

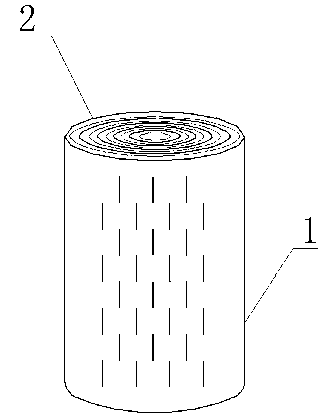

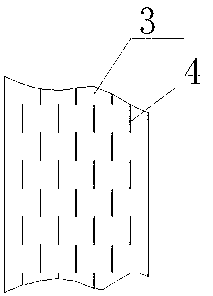

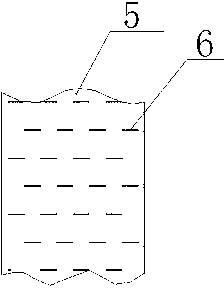

[0025] The anti-explosion filling material with composite structure to be protected by the present invention is formed by winding or stacking layers of multi-layer metal foil nets, and the shape of each unit body can be in the shape of a roll (see figure 1 ), polyhedral or spherical, etc., the meshes of the adjacent layers of metal foil mesh are different. The so-called different meshes mainly refer to different mesh structures, such as different mesh sizes, shapes, densities, and specifications. Metal foil nets with different mesh structures are alternately arranged to form the filling material, which avoids the structural defects of the filling material with a single structure and a single mesh specification commonly used in the prior art, and obtains higher and more uniform through structural improvement Consistent structural strength, effectively avoiding the short plate effect, reducing the collapse and deformation of the filling material, effectively reducing debris, red...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com