Method for firing art ceramic products

A technology of artistic ceramics and products, applied in the field of ceramics, can solve the problems of large temperature difference between day and night, wind and sand, etc., achieve the effect of natural glaze flow, simple texture, and large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1, a kind of firing method of art ceramics, concrete steps are as follows:

[0029] (1) Raw material ingredients

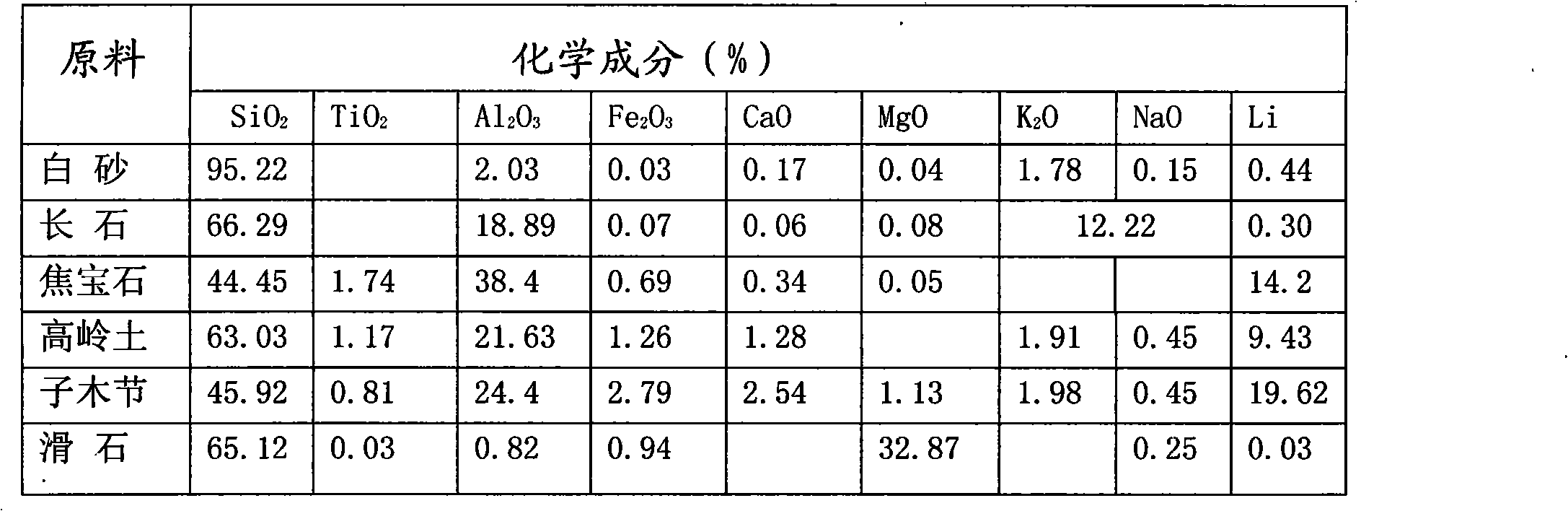

[0030] a. Material preparation: pick out the stones, iron and other impurities mixed with raw materials, according to the proportion of raw materials: white sand 15%, feldspar 5%, burnt gem 6%, kaolin 50%, sub-wood knot 20%, talc 4%, accurately weigh various required raw materials, the chemical composition of each raw material is shown in Table (1), put into the wet ball mill, ball stone: raw material: water=1.6~2.0: 1: 0.4~0.45;

[0031] b. Grinding: Determine the grinding time and slurry fineness according to the fineness required by the formula, generally 16-20 hours / grinding, the slurry fineness is 100 mesh sieve, and the slurry specific gravity is 1.6-1.7;

[0032] (2) Forming: Gypsum mold is used for grouting molding, and the grouting time is determined according to the size of the green body for 45 to 90 minutes, and the thickness of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com