Support method for high stress roadway coal-rock mass

A technology for coal rock mass and high stress, which is applied to the support field of high stress roadway coal rock mass, can solve the problems of insufficient strength of chemical slurry, unsatisfactory support effect, loss of support function, etc. The effect of eliminating high stress and improving self-supporting capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

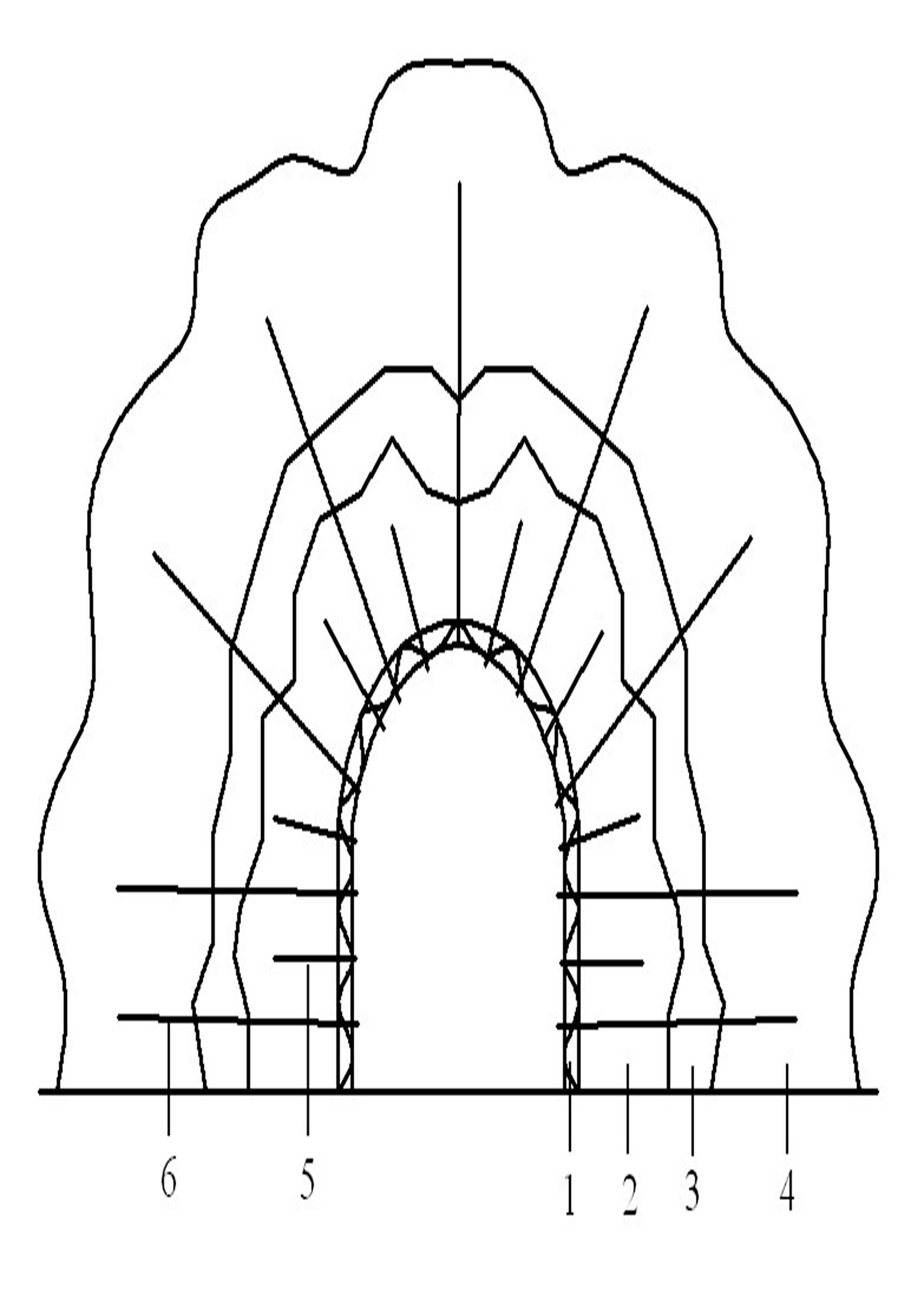

[0019] Implement the support method of a kind of high-stress roadway coal rock mass provided by the present invention, through the scientific and rational application of the anchoring and grouting support method, combined with the composition of the surrounding rock mass of the roadway, the surface surrounding rock is used to construct a strong and tough transition seal layer, The shallow surrounding rock is constructed as a rigid layer, and the deep surrounding rock is in-situ modified into a flexible layer, which changes the properties of the broken coal and rock mass under high stress conditions, strengthens the self-bearing capacity of the surrounding rock, and realizes high stress and The anchor-grouting support system for broken coal and rock mass ensures the stability of the surrounding rock of the high-stress roadway.

[0020] Because the surrounding rock of the roadway is highly stressed and easily broken, the ordinary grouting method is used for drilling. When the dri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Initial setting time | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com