Closed loop control method for SCR (Selective Catalyst Reduction) system of all-working-condition diesel engine

A SCR system, closed-loop control technology, applied in mechanical equipment, engine components, combustion engines, etc., can solve the problems of low system control accuracy, inability to timely feedback, and inability to obtain diesel engine speed and load parameters, and achieve the effect of reducing NOx emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

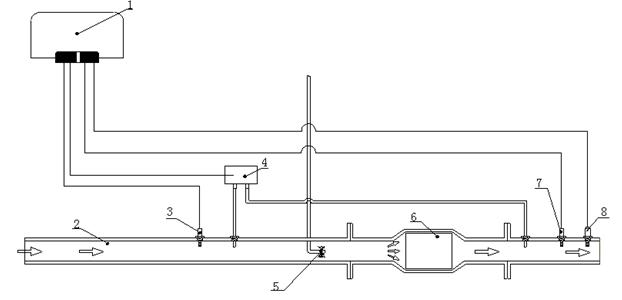

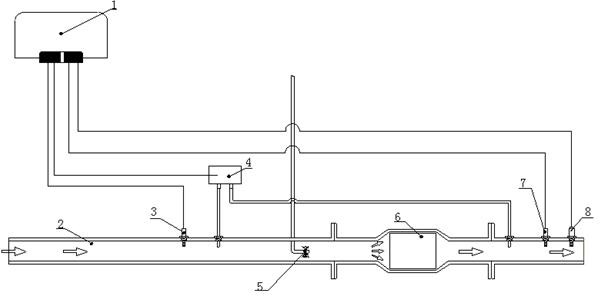

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

[0017] The closed-loop control method of the SCR system of the diesel engine under all working conditions is carried out according to the following steps: (1) establish a new three-dimensional matrix of the reductant dosage of the SCR system based on the exhaust temperature and exhaust back pressure of the diesel engine under all working conditions; (2) use Nitrogen oxide sensor and PID controller form a closed-loop accurate control mode of the SCR system of the diesel engine under all working conditions;

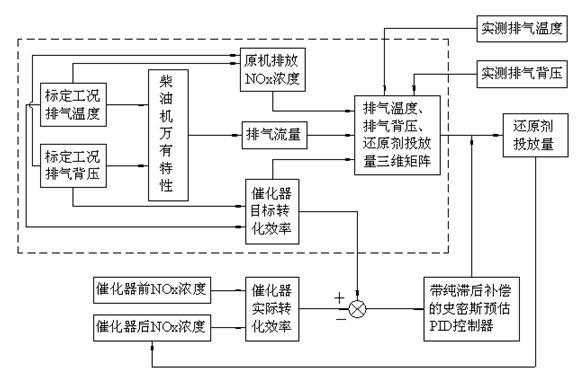

[0018] The present invention as figure 2 As shown, under the calibration condition, the exhaust gas flow rate based on the exhaust temperature and exhaust back pressure is obtained from the universal characteristics of the diesel engine; at the same time, the original engine emission NO x Concentration, catalytic converter target conversion ratio, exhaust gas temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com