Coal powder combustion system used in high-moisture type coal oxygen-enriched combustion

A technology of oxygen-enriched combustion and pulverized coal combustion, which is applied to burners, burners, combustion methods and other directions of burning powder fuel, can solve the problems of large drying output, high water vapor content, low oxygen concentration, etc., and achieve pulverized coal deflagration. less likely effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

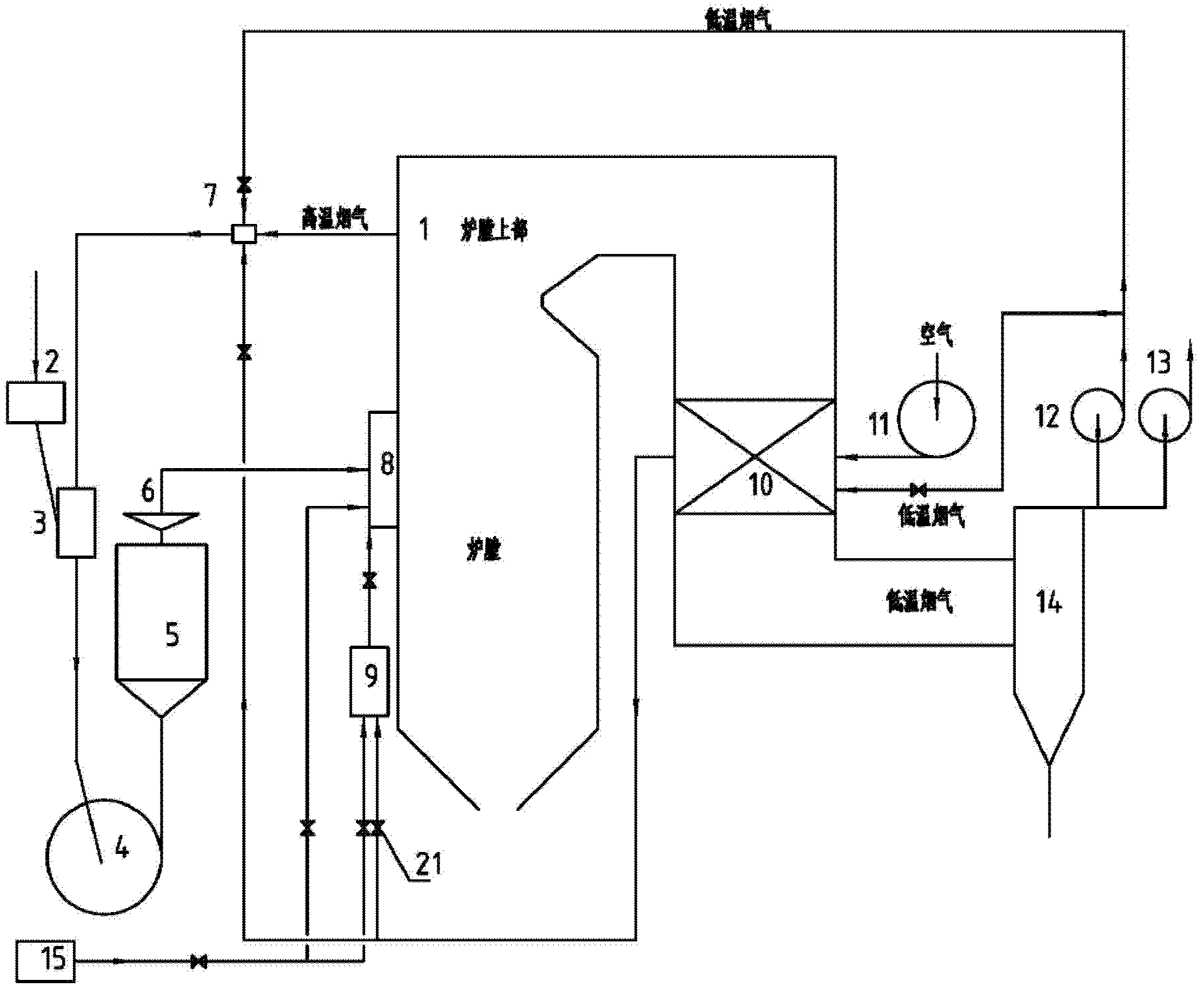

[0021] Below to figure 1 , image 3 Embodiments of the present invention will be described.

[0022] figure 1 It is an overall layout diagram of an embodiment of the oxyfuel combustion system. Such as figure 1 In the embodiment shown, the entire system includes a boiler body 1, a coal feeder 2, a descending drying pipe 3, a fan coal mill 4, a coarse powder separator 5, a pulverized coal distributor 6, a flue gas mixer 7, a burner 8, Secondary air box 9, air preheater 10, air blower 11, recirculation fan 12, induced draft fan 13, dust collector 14, oxygen making equipment 15, control valve 21.

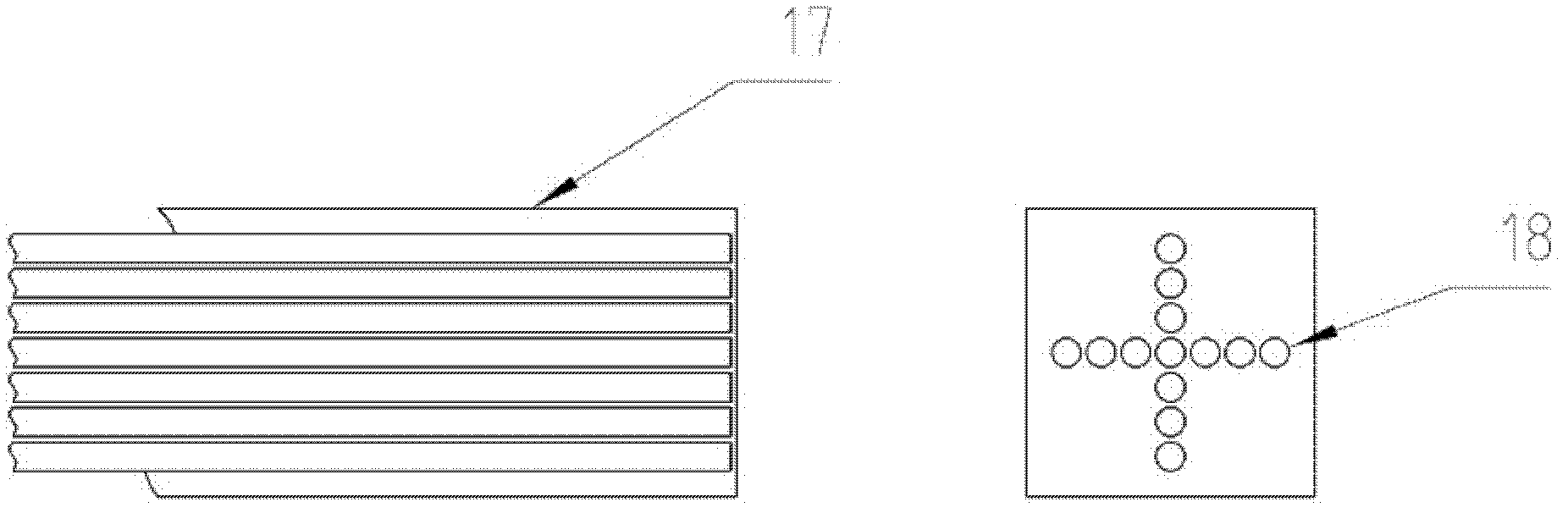

[0023] The primary air / powdered coal assembly in the burner 8 used in the combustion system is composed of two or more passages, of which the main passage passes through the pulverized coal and its conveying medium, and the other auxiliary passages pass hot air and oxygen-enriched air during air combustion. Take oxygen when burning. image 3 As an implementation form of the primar...

Embodiment 2

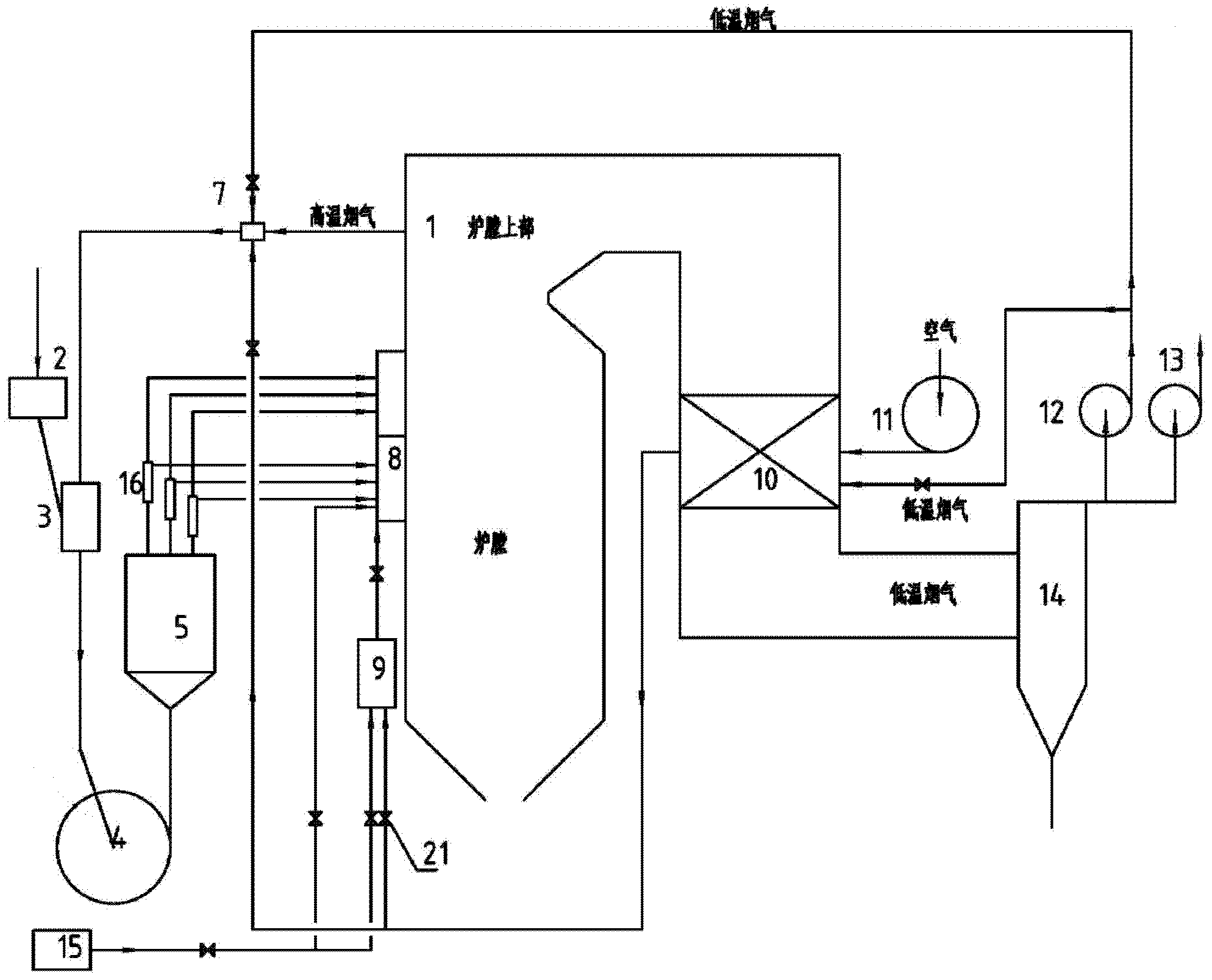

[0028] Below to figure 2 , image 3 Embodiments of the present invention will be described.

[0029] figure 2 It is an overall layout diagram of another embodiment of the oxyfuel combustion system. Such as figure 2In the embodiment shown, the entire system includes a boiler body 1, a coal feeder 2, a descending drying pipe 3, a fan coal mill 4, a coarse powder separator 5, a smoke-air mixer 7, a burner 8, a secondary air box 9, and an air Preheater 10, air blower 11, recirculation fan 12, induced draft fan 13, dust collector 14, oxygen making equipment 15, exhaust gas separator 16. In this system, the burner 8 is arranged in two layers, namely the lower main burner and the upper exhaust gas burner. The airflow at the outlet of the fan coal mill 4 can be separated by the exhaust air separator 16 . The outlet of the exhaust gas separator 16 is divided into two paths, one path means that a small part of the airflow and most of the pulverized coal can be separated and ent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com