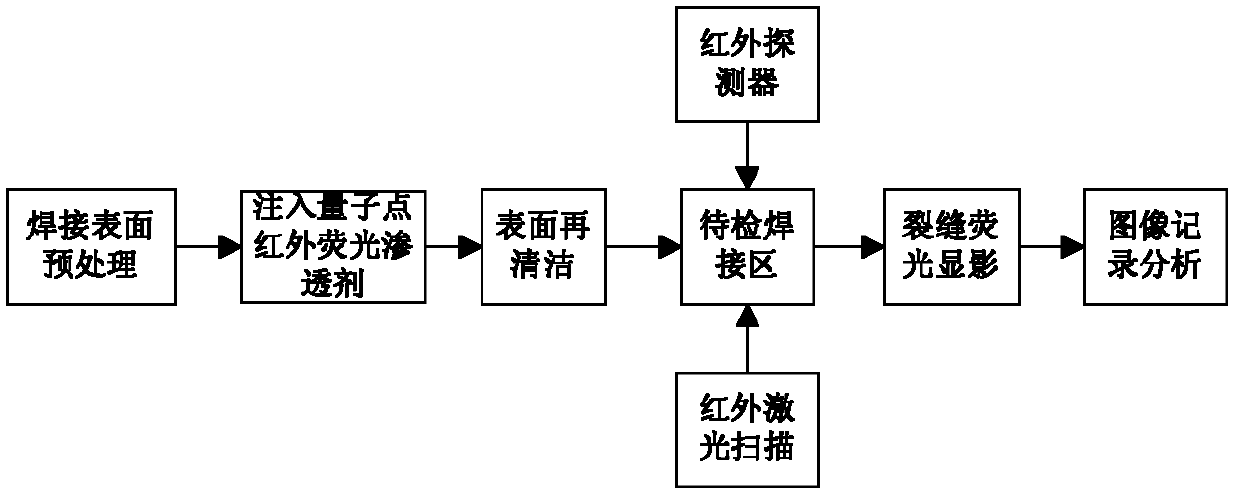

Method for detecting welding seam on basis of quantum dot infrared fluorescence display technology

A technology of infrared fluorescence and display technology, which is applied in the field of non-destructive detection of nano-scale metal welds, and can solve the problems of cumbersome detection process and low detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0040] Embodiment: Man-made scratches between 5 μm and 100 μm in the metal surface,

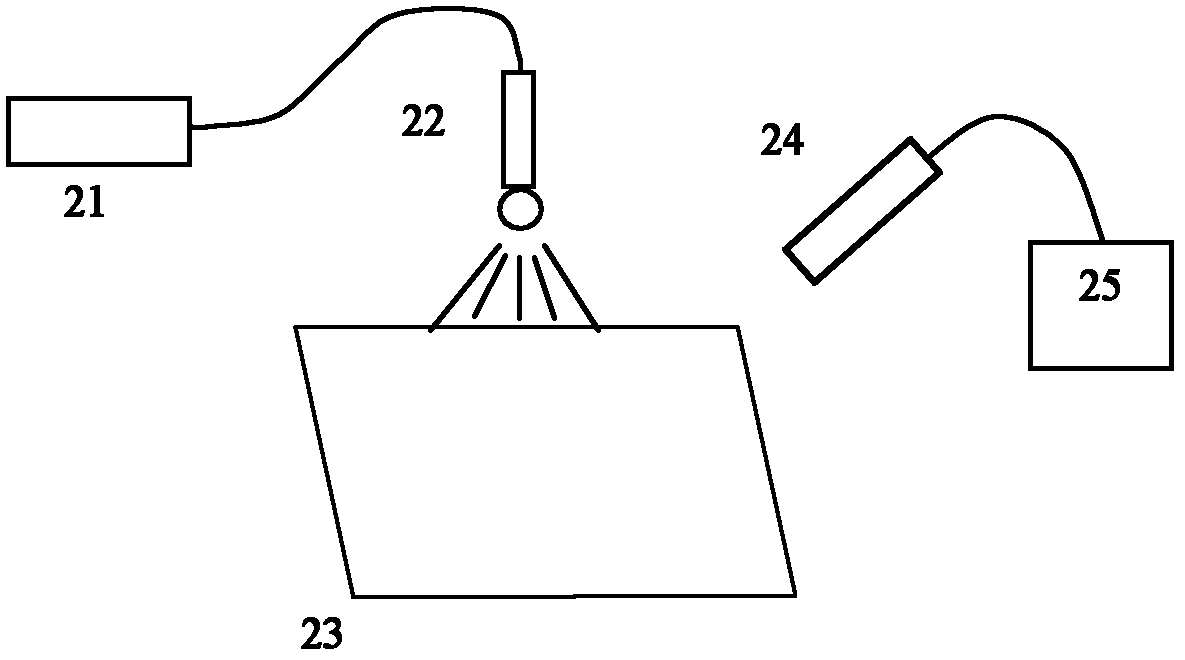

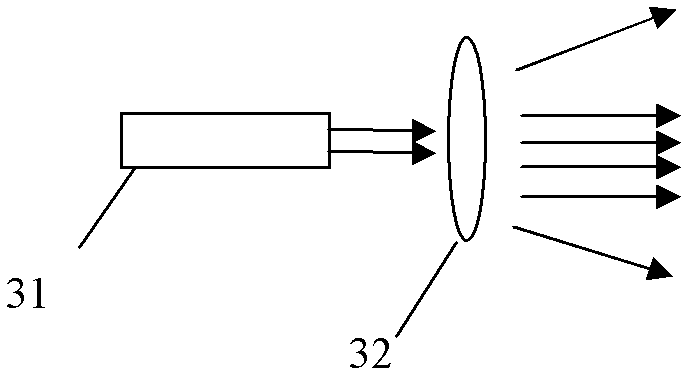

[0041] From step (1), preliminary cleaning is carried out on the metal surface. From step (2), the colloid immobilized with the quantum dot material is coated on the metal welding surface to be tested, so that the colloid penetrant can fully penetrate. Here, quantum dots with a line size of 5nm are used. From step (3), after standing for a few minutes, until the colloid is basically fixed, clean the metal surface penetrant residue containing scratches with acetone. From step (4), turn on the power of the infrared laser and let the laser pass through figure 2 The middle beam expander 22 expands the beam output by the infrared laser to a width of 6 cm. The expanded beam laser scans the metal plate along a fixed direction to realize the development of infrared fluorescence. Real-time infrared fluorescence capture is carried out through the detector, and the image of infrared fluorescence is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com