Galvanometer type laser direct writing photoetching machine

A laser direct writing and lithography technology, applied in microlithography exposure equipment, optics, optical components, etc., can solve the problems of slow control and response speed, the influence of writing patterns, and the limitation of the number of beams, so as to improve the running speed. , The effect of improving the writing speed and shortening the time consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

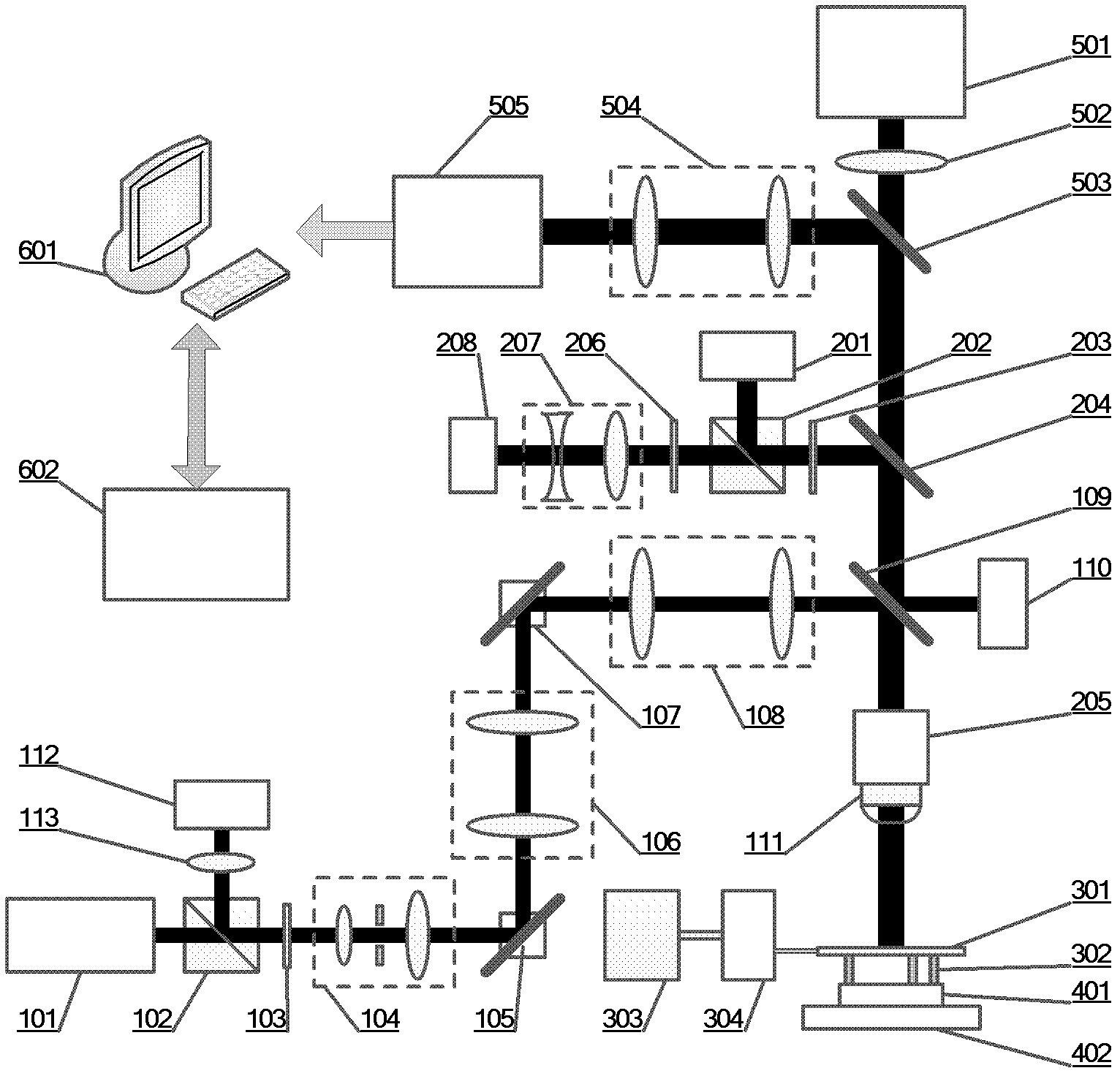

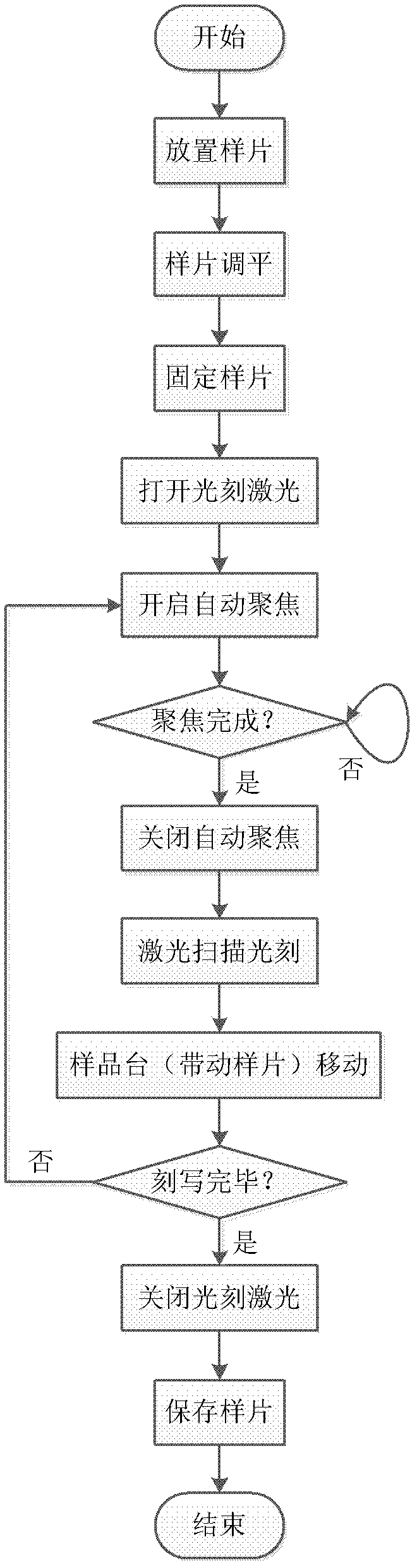

[0101] Embodiment 1 is a laser direct writing lithography machine, which can write gratings and arbitrary graphics. The writing form can be focused laser direct writing and zoom laser direct writing. The main work flow is as follows image 3 Shown.

[0102] First, place the sample on the sample stage 301, adjust the posture of the sample with the help of the sample monitoring module; when the sample is in a proper posture, run the sample stage module to level the sample even if the sample is parallel to the focal plane of the objective lens; The basis for sample leveling comes from the auto-focus module, so the sample leveling process is accompanied by the focusing of the objective lens; when the upper surface of the sample is coincident with the focal plane of the objective lens, turn on the vacuum suction device, fix the sample on the sample stage 301, and then open it Lithography laser 101; turn on the auto focus module to make the system in focus, then turn off the auto focus ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com