Method for improving abnormal crystalline silicon solar cell

An unusual technology for solar cells, applied in circuits, electrical components, sustainable manufacturing/processing, etc., can solve problems such as unfavorable large-scale production, low safety factor, and increased fragmentation rate, so as to improve photoelectric conversion efficiency without risk Gas, avoiding the effect of thermal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The present invention is described by taking a single crystal as an example.

[0019] The electrical performance parameters of the abnormal sheet 1 are as follows: the series resistance Rs is 21 mΩ, the fill factor FF is 69.5%, and the efficiency is 15.93%.

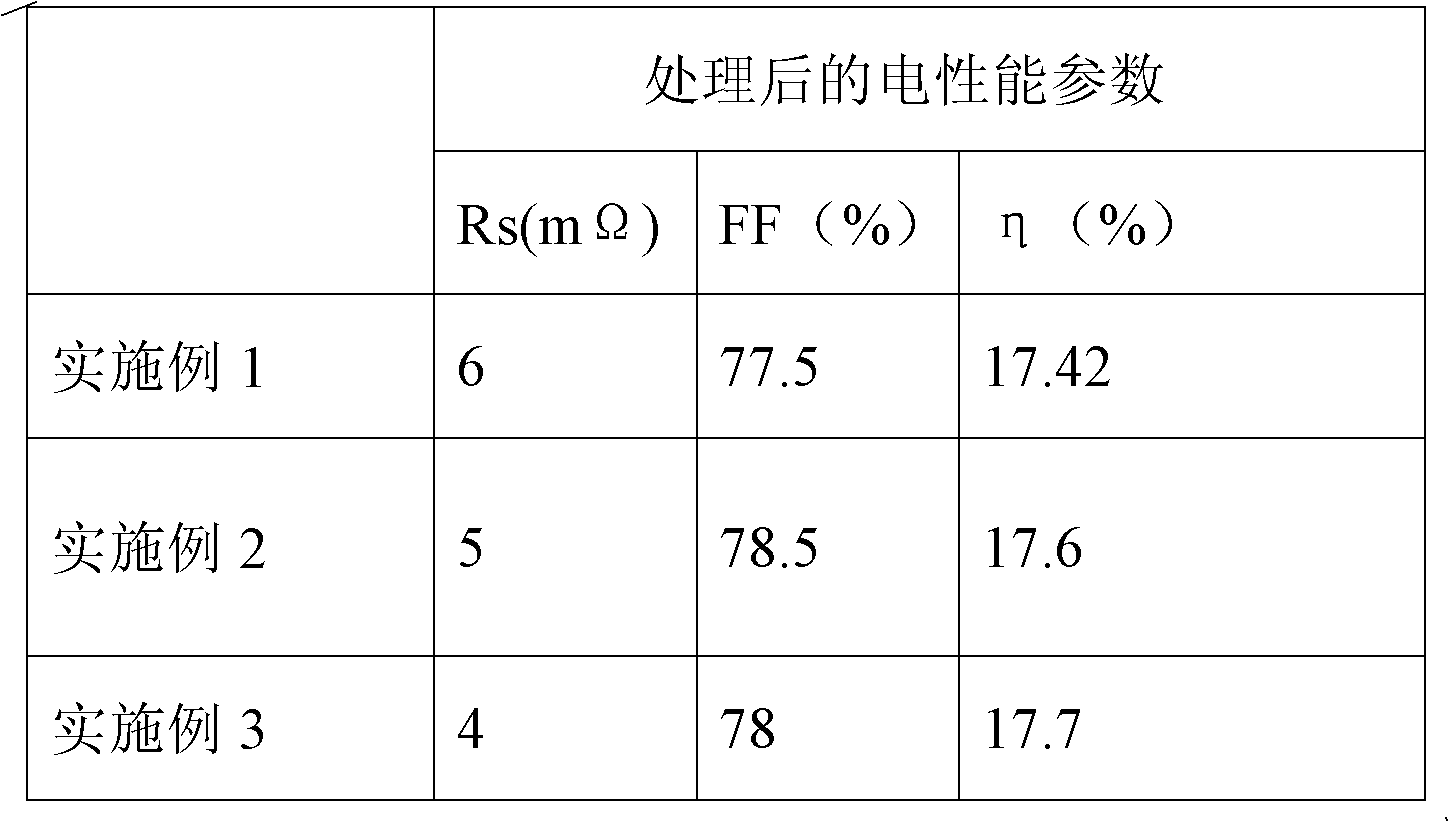

[0020] After immersing the abnormal sheet in HF acid with a mass concentration of 5% for 30 seconds, rinse it with deionized water (60 seconds), and blow it dry with nitrogen; take the processed battery sheet to the sorting tester for re-sorting Selected test, the results are shown in Table 1, the product is qualified. It can be seen that the present invention can obviously improve the abnormality of the solar cells, increase the photoelectric conversion efficiency of the cells (increase by 1.5%), and improve the qualified rate of finished products. The method is time-consuming, has high processing efficiency, and is highly operable.

Embodiment 2

[0022] The present invention is described by taking a single crystal as an example.

[0023] The electrical performance parameters of the abnormal sheet 2 are as follows: the series resistance Rs is 12 mΩ, the fill factor FF is 70.2%, and the efficiency is 16.05%.

[0024] After immersing the abnormal sheet in HF acid with a mass concentration of 3% for 60 seconds, rinse it with deionized water (55 seconds), and blow it dry with nitrogen; take the processed battery sheet to the sorting tester for re-sorting Selected test, the results are shown in Table 1, the product is qualified. It can be seen that the present invention can obviously improve the abnormality of the solar cells, increase the photoelectric conversion efficiency of the cells (increase by 1.55%), and improve the qualified rate of finished products. The method is time-consuming, has high processing efficiency, and is highly operable.

Embodiment 3

[0026] The present invention is described by taking a single crystal as an example.

[0027] The electrical performance parameters of the abnormal sheet 3 are as follows: the series resistance Rs is 10 mΩ, the fill factor FF is 71%, and the efficiency is 16.2%.

[0028] After immersing the abnormal sheet in HF acid with a mass concentration of 1.5% for 90 seconds, rinse it with deionized water (65 seconds), and blow it dry with nitrogen; take the processed battery sheet to the sorting tester for re-sorting Selected test, the results are shown in Table 1, the product is qualified. It can be seen that the present invention can obviously improve the abnormality of the solar cells, increase the photoelectric conversion efficiency of the cells (increase by 1.5%), and improve the qualified rate of finished products. The method is time-consuming, has high processing efficiency, and is highly operable.

[0029] Table 1 Use HF acid to improve the electrical performance parameters of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com