Compound full-power wind power converter

A wind power converter, full power technology, applied in the direction of converting AC power input to DC power output, converting AC power input to AC power output, wind power generation, etc., can solve the waste of resources, full power converter design and control Complicated, unable to adapt to new requirements and other issues, to achieve the effect of improving system reliability, facilitating system maintenance, and improving system reliability and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing.

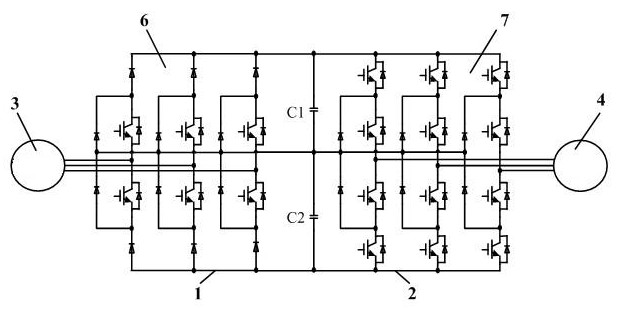

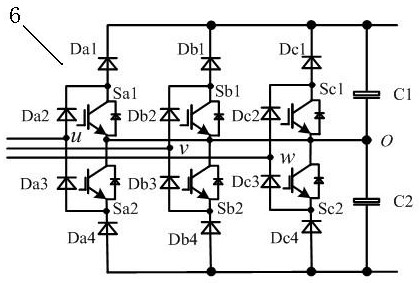

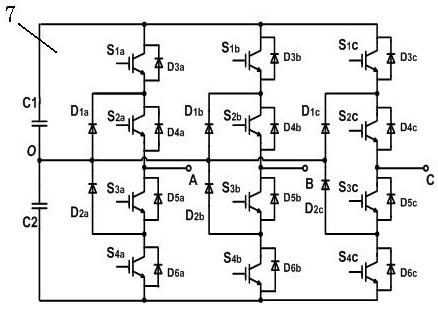

[0021] Such as figure 1 As shown, a composite full-power wind power converter includes a machine-side converter 1, a grid-side converter 2, a wind turbine 3, a power grid 4, and DC side filter capacitors C1 and C2. The machine-side converter 1 is composed of a two-quadrant three-level Vienna rectifier 6, and the grid-side converter 2 is composed of a voltage-type diode mid-point clamped three-level converter 7 using power devices with controllable switches. The AC input of the Vienna rectifier 6 The terminal is connected to the wind power generator 3, and its DC output terminal is connected to the DC bus side of the voltage-type diode mid-point clamped three-level converter 7 through the DC-side filter capacitors C1 and C2, and the voltage-type diode mid-point clamp type The AC side of the three-level converter 7 is connected to the grid 4 .

[0022] Vienna rectifier 6 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com