High-frequency high-voltage power supply for electrostatic precipitation, and control method of the same

A high-frequency high-voltage power supply, electrostatic precipitator technology, applied in electrical components, circuit devices, output power conversion devices, etc., can solve the problems of increased energy loss of transformers, low output power, large leakage inductance and parasitic capacitance of transformers, etc. To achieve the effect of convenient maintenance and debugging, high reliability and flexible control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below with reference to the drawings and specific embodiments.

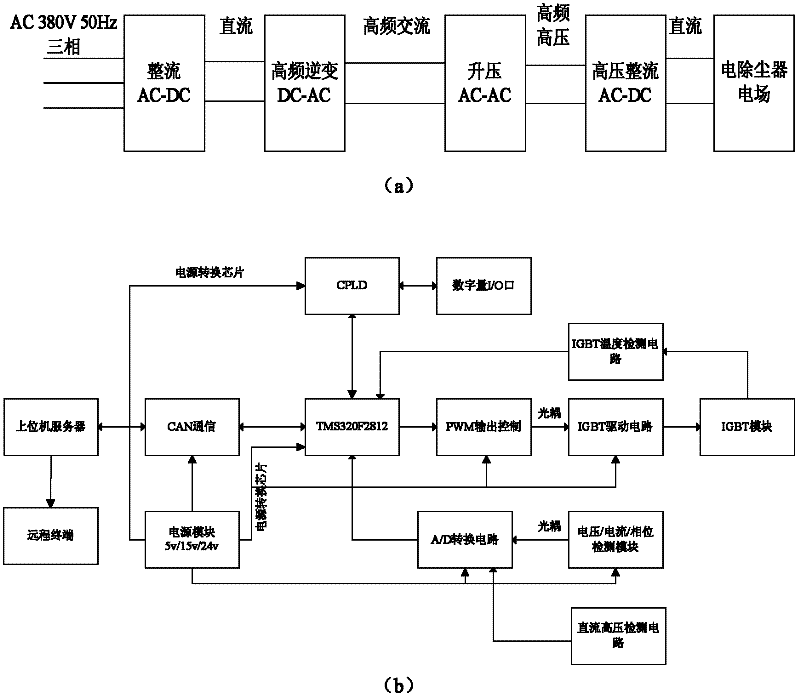

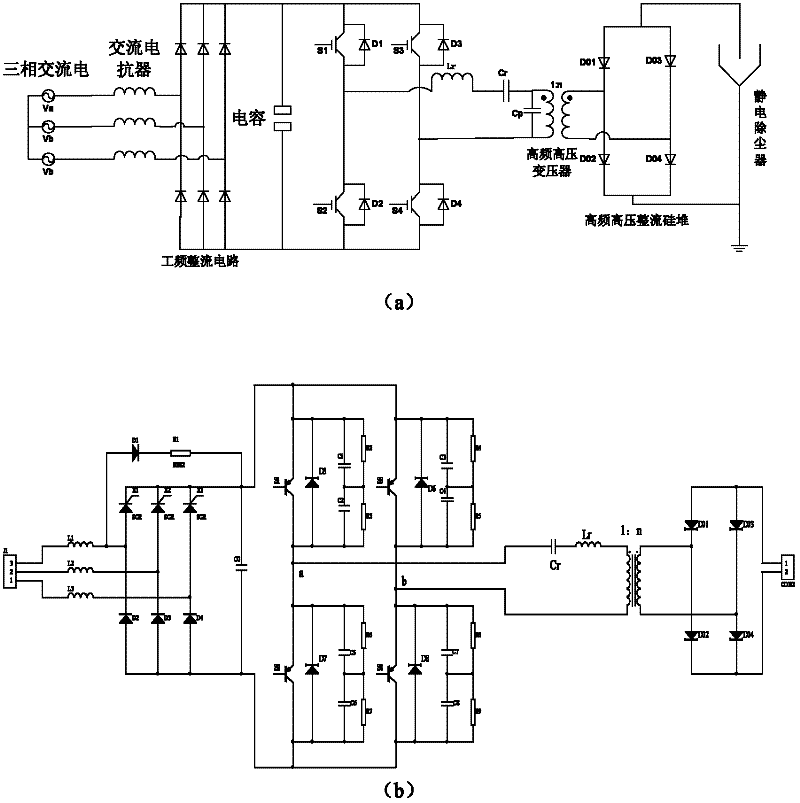

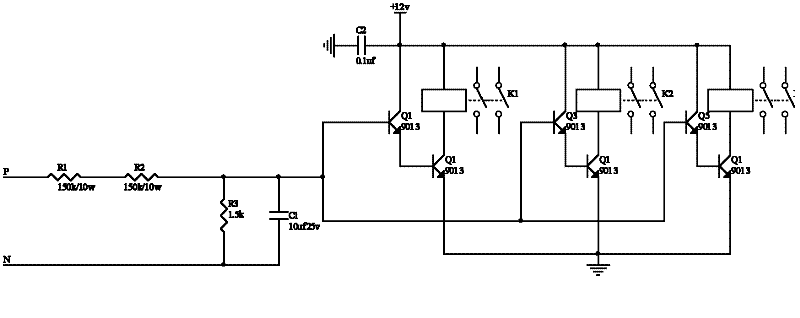

[0017] Such as figure 1 and figure 2 As shown, a high-frequency high-voltage power supply for electrostatic dust removal includes a rectifier module, a high-frequency inverter module, a transformer module and a high-voltage rectifier module, and each module collects current and voltage. For the full-bridge inverter circuit The IGBT module is equipped with a temperature detection circuit, which collects the spark frequency and relevant signals inside the electrostatic precipitator in real time, monitors the internal parameters of the power supply online and then monitors the operating status of the power supply; all collected field data are uploaded to the host computer server and stored in The database, based on the data obtained from status monitoring, combined with the history of power supply operation, performs fault diagnosis; the remote terminal perfor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com