Fixed-frequency integral controller of brushless direct-current motor and construction method thereof

A technology of brushed DC motor and constant frequency integration, which is applied in motor generator control, electronically commutated motor control, single motor speed/torque control, etc., can solve the problem of poor dynamic response, weak robustness, and unsatisfactory Control requirements and other issues, to achieve the effect of strong anti-load disturbance ability, good robustness, and simple construction method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

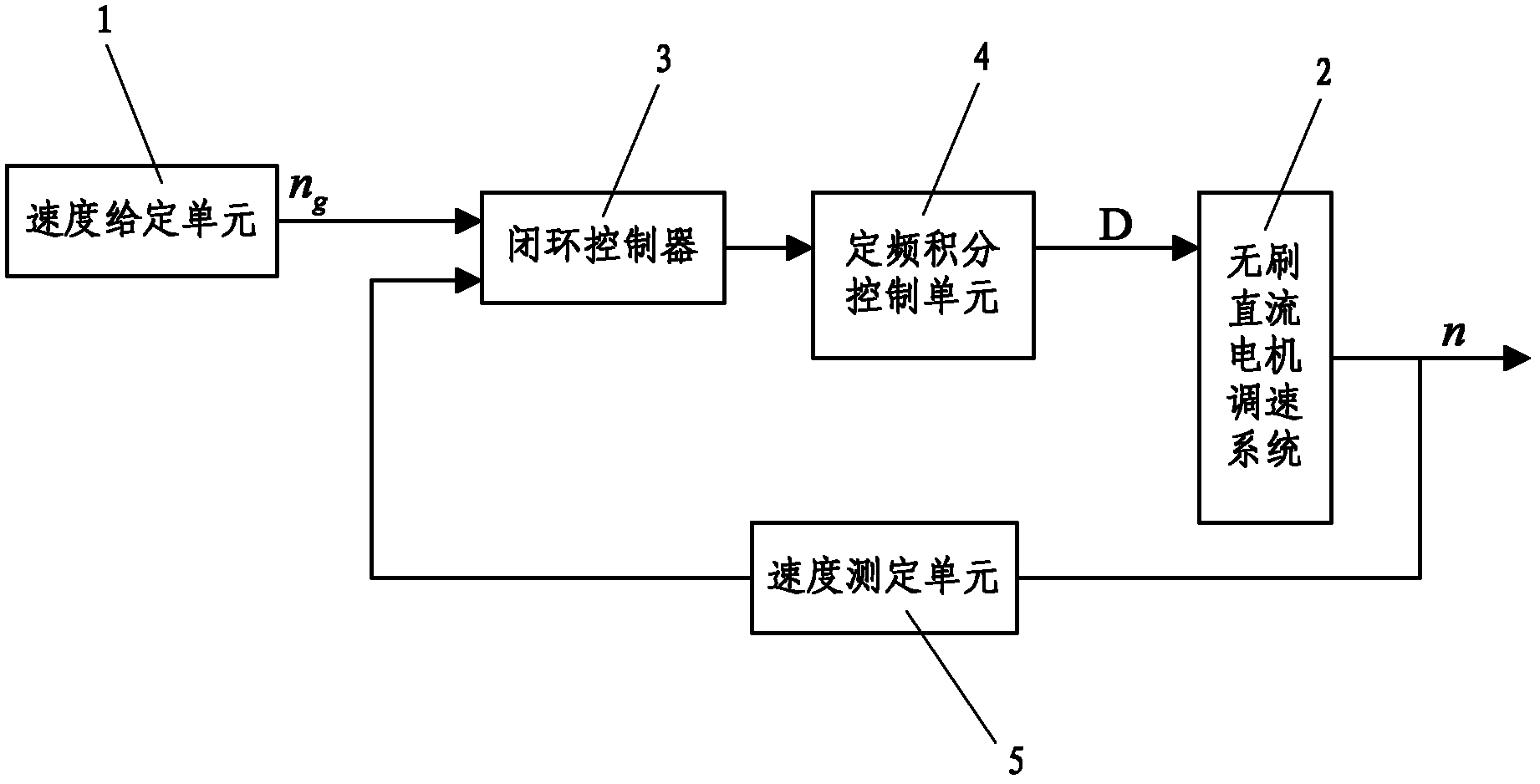

[0046] Such as figure 1 As shown, the brushless DC motor fixed-frequency integral controller of the present invention includes a speed setting unit 1, a brushless DC motor speed control system 2 and a speed measuring unit 5 that detects the actual speed of the brushless DC motor. A closed-loop controller 3 and a fixed-frequency integral control unit 4 connected in series with the closed-loop controller 3 are connected between the speed setting unit 1 and the brushless DC motor speed control system 2. The closed-loop controller 3 is connected to the speed setting list. Element 1 is connected to the speed measuring unit 5 and used to control the fixed frequency integral control unit 4 according to the given speed and the actual speed of the brushless DC motor, and the fixed frequency integral control unit 4 is connected to the brushless DC motor speed regulation system 2 It is also used for constant frequency integral control of the brushless DC motor speed control system 2.

[004...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com