Liquid milk and preparation method thereof

A technology of liquid milk and feed liquid, which is applied in the direction of milk preparations, dairy products, applications, etc., can solve the problems that affect the stability of product organization state, product sensory perception, and reduce the qualified rate of products, so as to enrich nutrition and increase product types , mellow taste and mouthfeel effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

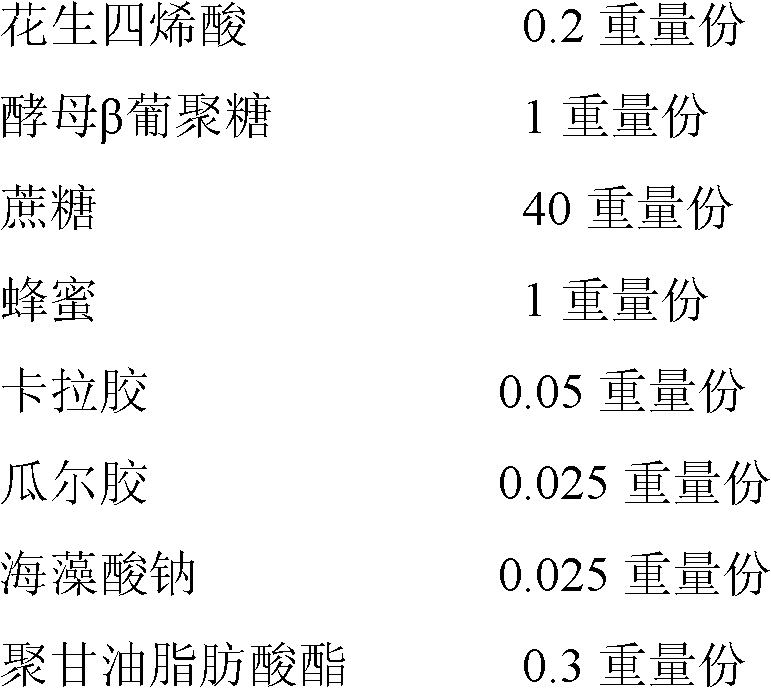

[0028] Embodiment 1 prepares liquid milk (1000 parts by weight)

[0029] The composition of every 1000 parts by weight of liquid milk (in parts by weight):

[0030]

[0031]

[0032] The preparation method comprises the following steps:

[0033] 1. Processing of pasteurized milk:

[0034] 11 Raw milk collection: mainly for sensory indicators, acidity, fat, protein, whole milk solids, adulteration, alcohol test and other indicators to detect, after the indicators are qualified, the milk is collected.

[0035] 1.2 Filtration: Raw milk passes through a double filter to remove some larger impurities. The pressure difference between front and back reaches 1 bar to clean the filter; after the milk is collected, the filter is removed for inspection and cleaning;

[0036] 1.3 Cooling: cool down the received fresh milk to 1°C-8°C after plate replacement;

[0037] 1.4 Storage: Put the cooled milk into raw milk tanks for storage at a temperature of 1°C to 8°C, and pasteurize wi...

Embodiment 2

[0055] Embodiment 2 prepares liquid milk (1000 parts by weight)

[0056] The composition of every 1000 parts of liquid milk (by weight):

[0057]

[0058] The preparation method and product characteristics are the same as in Example 1.

Embodiment 3

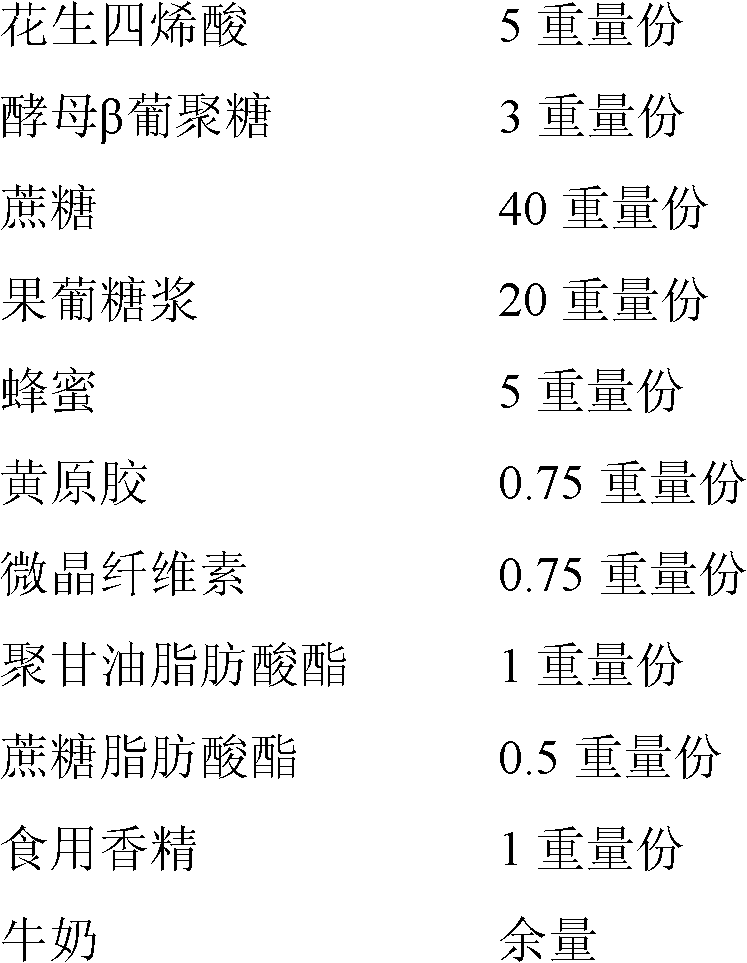

[0059] Embodiment 3 prepares liquid milk (1000 parts by weight)

[0060] The composition of every 1000 parts by weight of liquid milk (in parts by weight):

[0061]

[0062]

[0063] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com