Auxiliary implantable flexible microelectrode of non-absorbable suture line and production method thereof

A micro-electrode and implantable technology, applied in the direction of electrodes, internal electrodes, etc., can solve the problems of methods or systems without the accuracy of micro-electrode implantation parts, and less research on accuracy, so as to ensure accuracy and operability strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

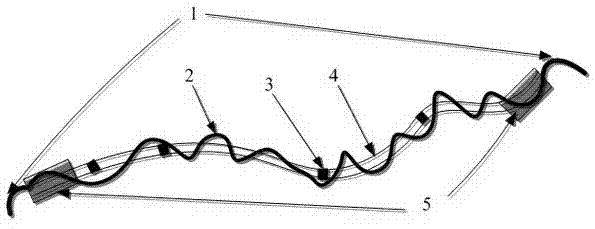

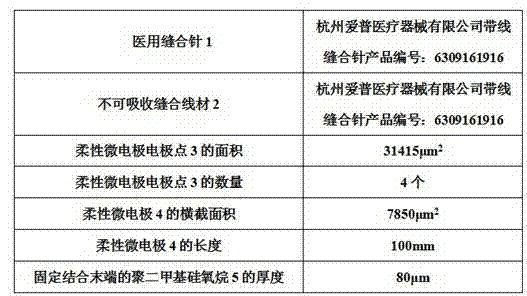

[0019] Such as figure 1 As shown, the non-absorbable suture-assisted implantable flexible microelectrode prepared in Example 1 includes: medical suture needle 1, non-absorbable suture wire 2, flexible microelectrode 4, polydimethylsiloxane 5 with fixed binding ends .

[0020] In this embodiment, the medical suture needle 1 is a variety of commercial surgical suture needles.

[0021] In this embodiment, the non-absorbable suture wire 2 is a commercially available non-absorbable suture needle with thread.

[0022] In this embodiment, the flexible microelectrode 4 can be a noble metal wire microelectrode (such as platinum wire, iridium wire, gold wire, etc.), a polymer microelectrode (such as a Parylene film microelectrode, a conductive polymer film microelectrode, etc. ) in one.

[0023] In this embodiment, the flexible microelectrode 4 is provided with electrode points 3, and there may be one or more flexible microelectrode electrode points 3.

[0024] In the p...

Embodiment 2

[0035] This embodiment provides a preparation method of the nonabsorbable suture-assisted implantable flexible microelectrode described in Embodiment 1. The specific preparation process is as follows: firstly, the flexible microelectrode 4 (here, a platinum wire electrode is used as an example) is combined with a nonabsorbable suture The suture wire 2 is helically wound together, and the wire should not be too loose, and it is advisable to see the contact between the wire and the platinum wire electrode with the naked eye. Then apply an appropriate amount of polydimethylsiloxane to the joint end of the wire and the platinum wire electrode, and finally heat-treat in an oven at 70°C for 6 hours.

[0036] In this embodiment, the polydimethylsiloxane 5 at the bonding end of the non-absorbable suture wire 2 and the flexible microelectrode 4 has a mass ratio of silicone rubber to curing agent of 10:1.

[0037] In this embodiment, when winding the microelectrode, the medical su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Area | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com