Flower-like titanium dioxide microsphere photocatalytic material and preparation method thereof

A photocatalytic material, titanium dioxide technology, applied in the field of photocatalysis, can solve the problems of complex process, poor repeatability, harshness, etc., and achieve the effect of low reaction temperature, short preparation cycle and mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Add secondary water, hydrogen peroxide and hydrochloric acid into the polytetrafluoroethylene lining of the reaction kettle so that the concentrations of hydrogen peroxide and hydrochloric acid are 1.2mol / L and 1.6mol / L respectively. Then, add 1.2×10 -4 mol of titanium trichloride, stirred evenly, put the mixture in a high-pressure reactor, put it in an oven at 180°C, and react for 18 hours.

[0020] After the reaction kettle was cooled to room temperature, the supernatant was absorbed and discarded. The lower precipitate was centrifuged and washed 6 times with secondary water. After washing, put the precipitate into an oven at 60° C. for 12 hours in vacuum to dry to obtain flower-shaped spherical microsphere titanium dioxide photocatalyst.

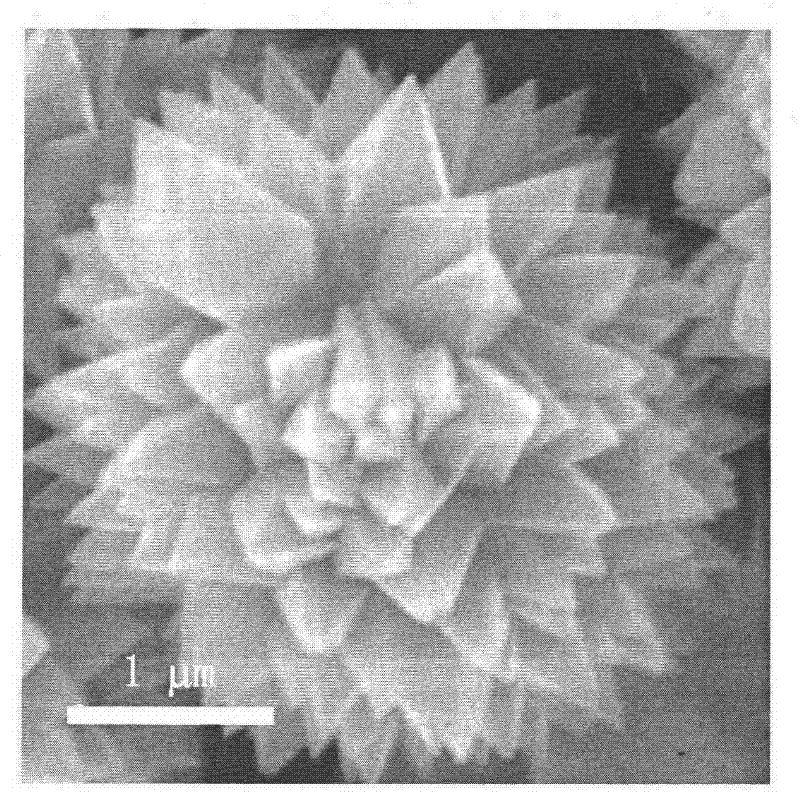

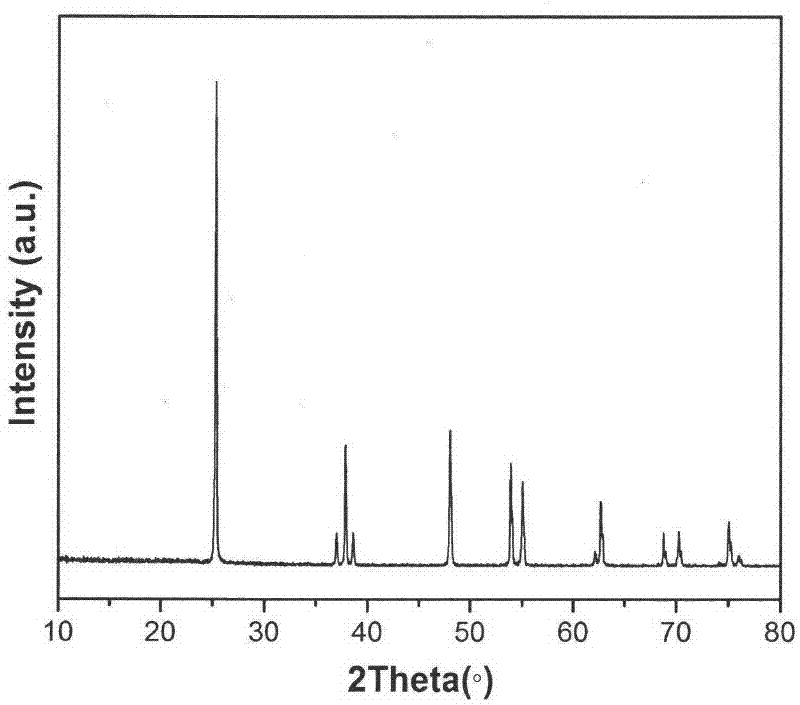

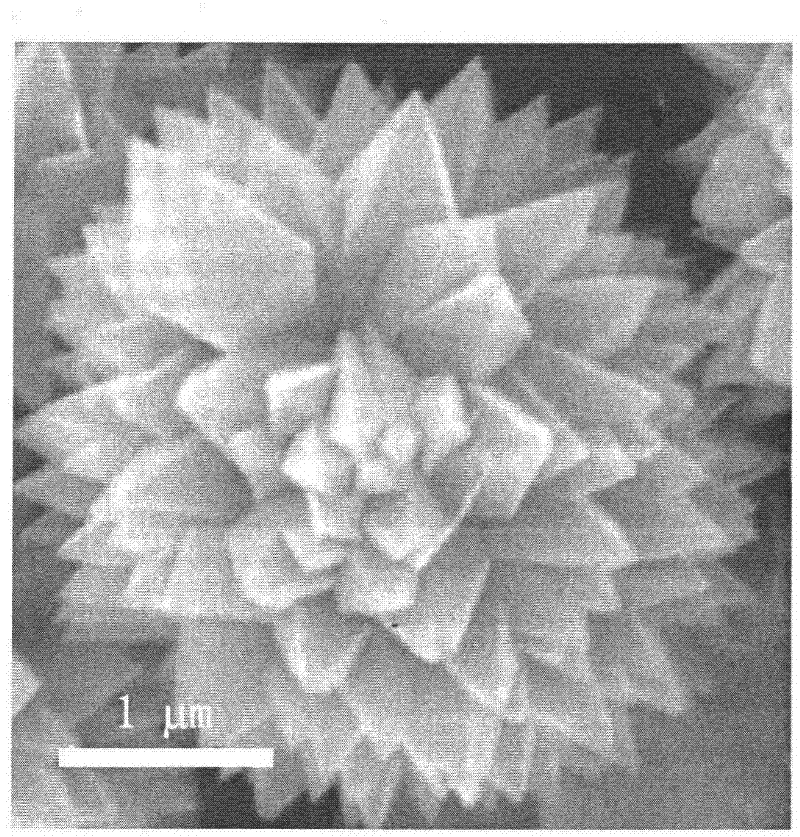

[0021] The scanning electron microscope figure of embodiment 1 gained product is as figure 1 As can be seen from the figure, the resulting product is a flower-shaped microsphere assembled from a double-pyramid-shaped titanium di...

Embodiment 2

[0024] Add secondary water, hydrogen peroxide and hydrochloric acid into the polytetrafluoroethylene lining of the reaction kettle so that the concentrations of hydrogen peroxide and hydrochloric acid are 1.6mol / L and 1.6mol / L respectively. Then, add 1.2×10 -4 mol of titanium trichloride, stirred evenly, put the mixture in a high-pressure reactor, put it in an oven at 180°C, and react for 18 hours.

[0025] After the reaction kettle was cooled to room temperature, the supernatant was absorbed and discarded. The lower precipitate was centrifuged and washed 6 times with secondary water. After washing, put the precipitate into an oven at 60° C. for 12 hours in vacuum to dry to obtain flower-shaped spherical microsphere titanium dioxide photocatalyst.

Embodiment 3

[0027] Add secondary water, hydrogen peroxide and hydrochloric acid into the polytetrafluoroethylene lining of the reactor, so that the concentrations of hydrogen peroxide and hydrochloric acid are 2.4mol / L and 1.6mol / L respectively. Then, add 1.2×10 -4 mol of titanium trichloride, stirred evenly, put the mixture in a high-pressure reactor, put it in an oven at 180°C, and react for 18 hours.

[0028] After the reaction kettle was cooled to room temperature, the supernatant was absorbed and discarded. The lower precipitate was centrifuged and washed 6 times with secondary water. After washing, put the precipitate into an oven at 60° C. for 12 hours in vacuum to dry to obtain flower-shaped spherical microsphere titanium dioxide photocatalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com