Au nanoparticle catalyst and preparation method thereof

A gold nanoparticle and catalyst technology, applied in the field of gold nanoparticle catalysts, can solve the problems of poor catalyst stability and increased nanoparticle size, and achieve the effects of stable performance, uniform distribution and small particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

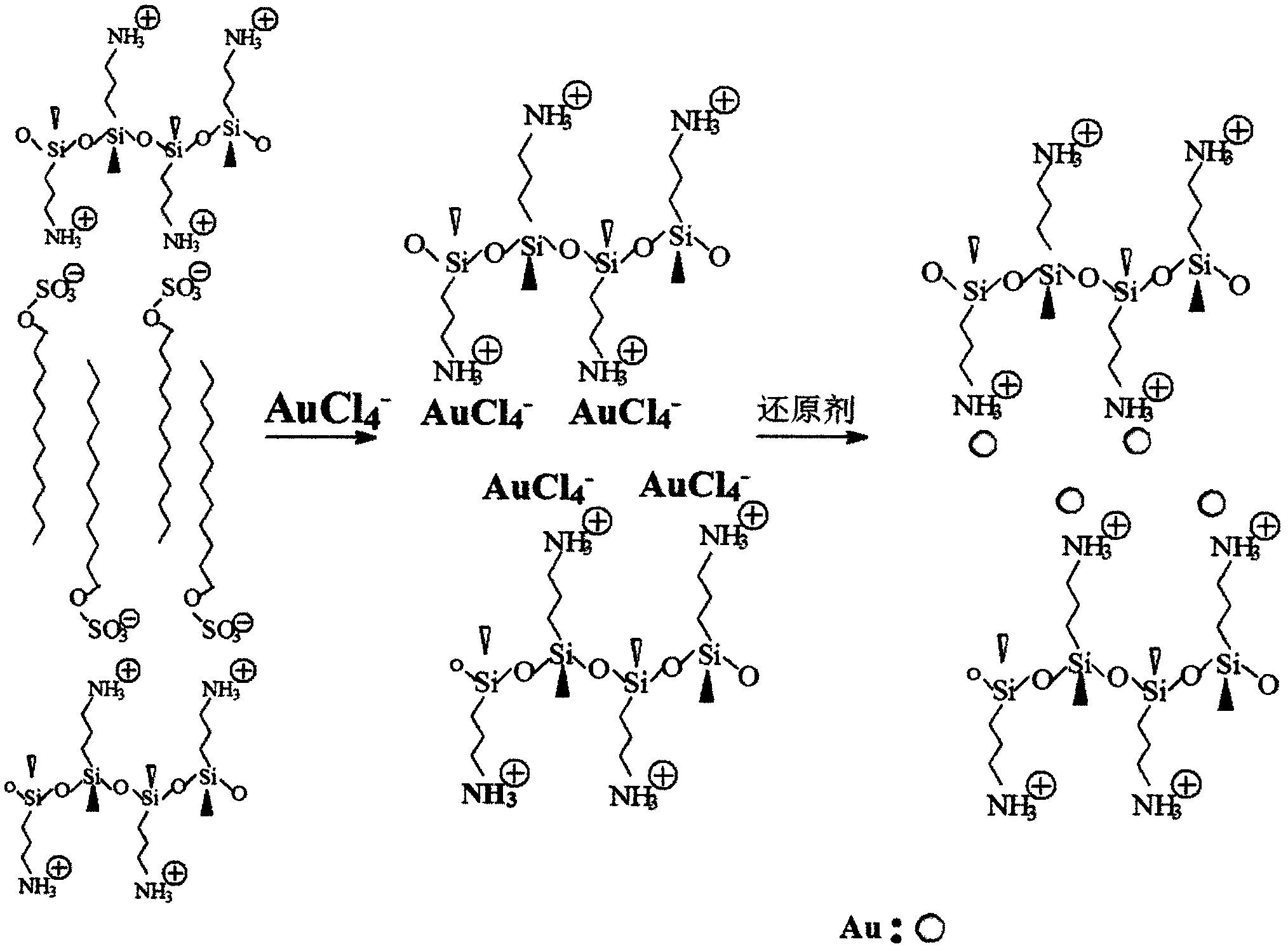

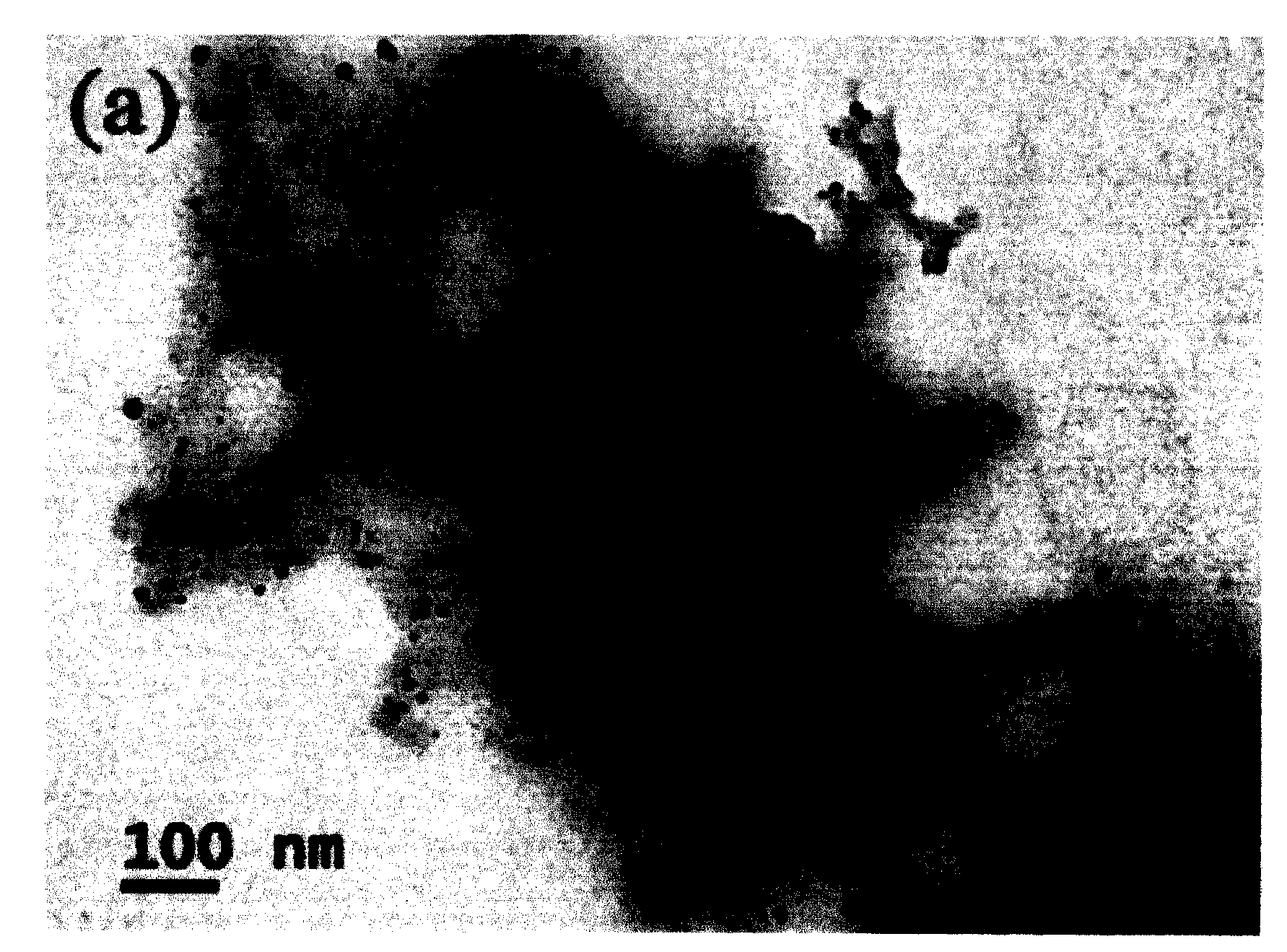

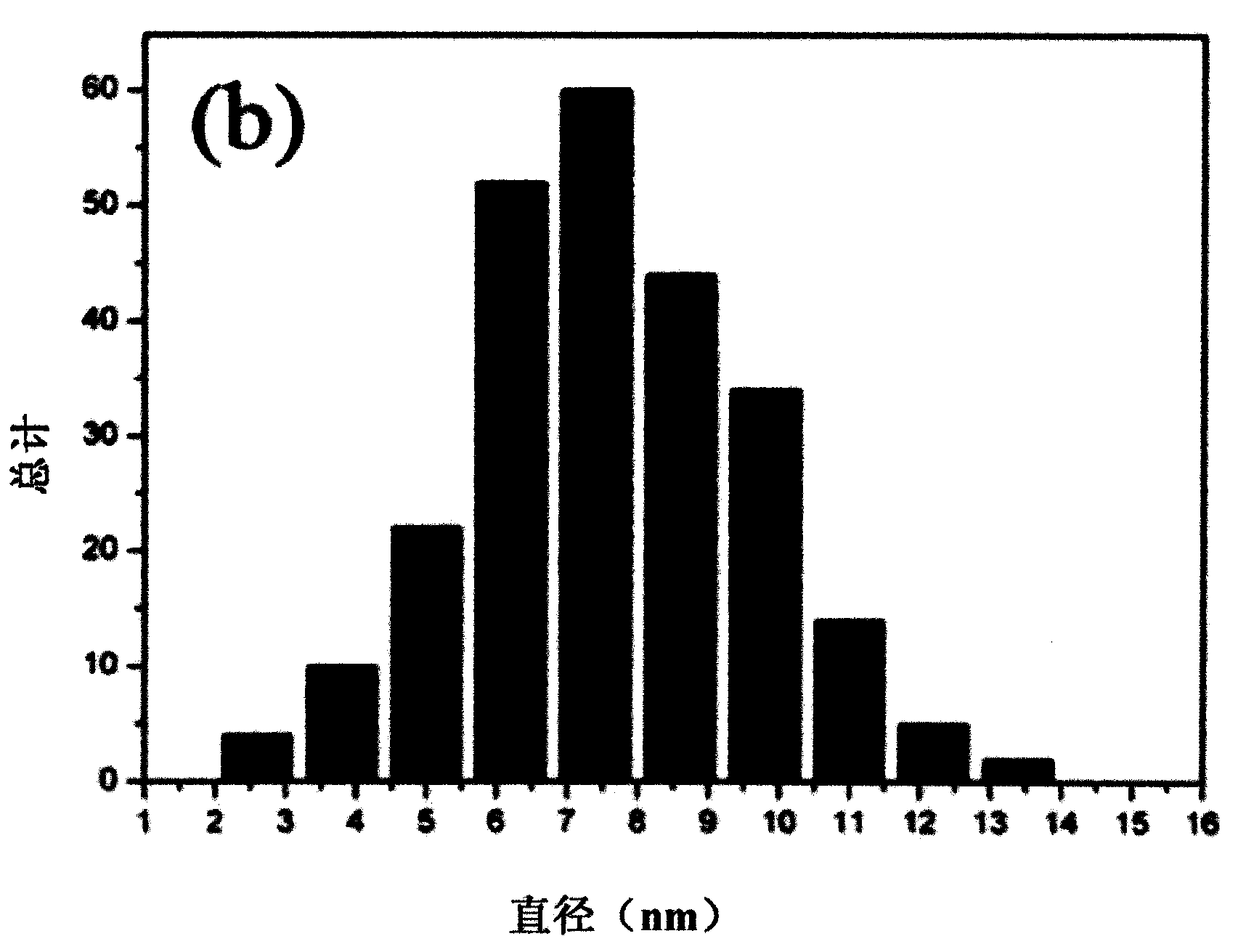

[0033] Example 1: see Figure 1 to Figure 3 , the preparation method of a gold nanoparticle catalyst of the present invention, it comprises the following steps:

[0034] (1) The silane compound with amino functional group is uniformly dispersed in the surfactant aqueous solution of 8-18wt% by mass percentage, so that the mass percentage of the silane compound with amino functional group is 5-15wt%, and then dilute acid Adjust the pH value of the mixed solution between 2 and 4, and react in a constant temperature water bath at 1 to 50°C for 18 to 72 hours, then centrifuge and filter the mixed solution, and wash it several times with deionized water and absolute ethanol , after vacuum drying for 12-48 hours, a two-dimensional silicon structure layered material with amino functional groups is obtained;

[0035] (2) Add the two-dimensional silicon structure layered material into absolute ethanol, and perform ultrasound to completely disperse the two-dimensional silicon structure ...

Embodiment 2

[0055] Embodiment 2: The gold nanocatalyst and preparation method thereof of the present embodiment are basically the same as embodiment 1, and its difference is: 3-aminopropyltrimethoxysilane is uniformly dispersed to 30mL mass percent and is 12wt% dodecane In an aqueous solution of sodium sulfate, make the mass percentage 10wt%, then adjust the pH value at 2.5 with dilute hydrochloric acid, react in a constant temperature water bath at 40°C for 24 hours, centrifuge, filter, wash with deionized water and absolute ethanol several times, and vacuum dry A two-dimensional silicon structure layered material is obtained.

[0056] Disperse the two-dimensional silicon structure layered material in 80mL absolute ethanol, its mass percentage is 1.5wt%, ultrasonic 40min makes it completely dispersed; Add the chloroauric acid solution in the ethanol solution of the two-dimensional silicon structure layered material, make chlorine The mass ratio of gold acid to the two-dimensional silicon...

Embodiment 3

[0058] Embodiment 3: The gold nanocatalyst of this embodiment and its preparation method are basically the same as Embodiment 1, 2, and its difference is: the 3-aminopropyltrimethoxysilane is uniformly dispersed to 25mL mass percent and is 9wt% ten In dialkyl sodium sulfate aqueous solution, make the mass percentage 6wt%, then adjust the pH value with dilute hydrochloric acid, react in a constant temperature water bath at 3, 4°C for 70h, centrifuge, filter, wash several times with deionized water and absolute ethanol, Vacuum drying to obtain a two-dimensional silicon structure layered material.

[0059] Disperse the two-dimensional silicon structure layered material in 40mL of absolute ethanol, its mass percentage is 0.2wt%, ultrasonic 1h makes it completely dispersed; Add the chloroauric acid solution in the ethanol solution of the two-dimensional silicon structure layered material, make chlorine The mass ratio of gold acid to the two-dimensional silicon structure layered mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com