Method of using magnesium-aluminum-iron ternary hydrotalcite-like to remove perchlorate in water

A perchlorate and water removal technology, applied in water/sewage treatment, chemical instruments and methods, adsorption water/sewage treatment, etc., can solve the problems of high economic cost and low perchlorate treatment efficiency, and achieve adsorption The effect of large capacity, good economic and environmental benefits, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] (1) Weigh 192.3075g magnesium nitrate hexahydrate, 75.026g aluminum nitrate nonahydrate and 20.201g ferric nitrate nonahydrate, namely [Mg 2+ ] / [Al 3+ ] / [Fe 3+ ]=3:0.8:0.2.

[0047] (2) Pour the mixed salt into a 500mL Erlenmeyer flask, mix well and then add 150mL deionized water to dissolve. If there are fine particles that cannot be dissolved, you can ultrasonicate for 3-5 minutes and stir on an electromagnetic stirrer. It will dissolve completely after half an hour The mixture is called a. Weigh 80.02g of anhydrous sodium hydroxide and 52.995g of anhydrous sodium carbonate, pour them into another 500mL conical flask, and quickly add 150mL of deionized water to dissolve them. After ~5min, electromagnetically stir evenly to obtain a completely dissolved solution b.

[0048] (3) Clean the two 150mL constant pressure funnels, dry them, and check their tightness. When ready, transfer most of the solutions a and b to the two constant pressure funnels, and reserve two p...

Embodiment 2

[0057] (1) Take by weighing 192.3075g magnesium nitrate hexahydrate, 56.2695g aluminum nitrate nonahydrate and 40.399g ferric nitrate nonahydrate, [Mg 2+ ] / [Al 3+ ] / [Fe 3+ ]=3:0.6:0.4.

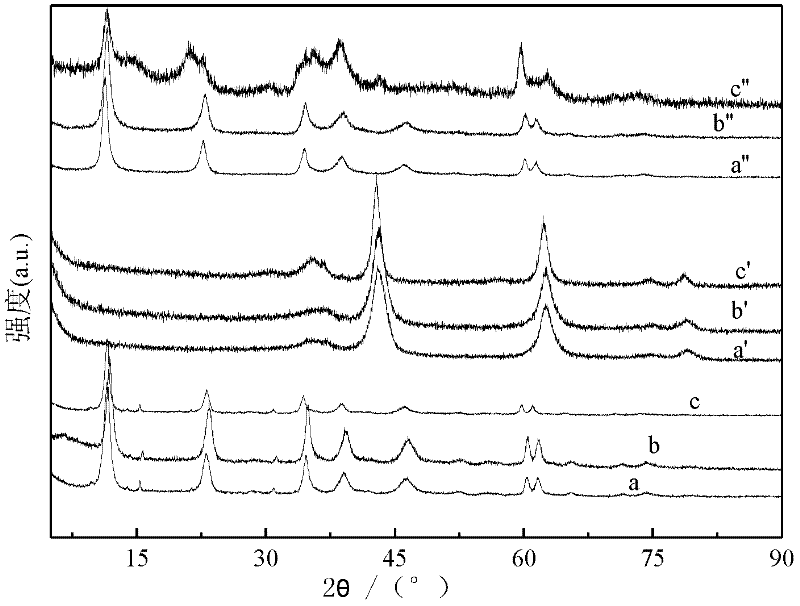

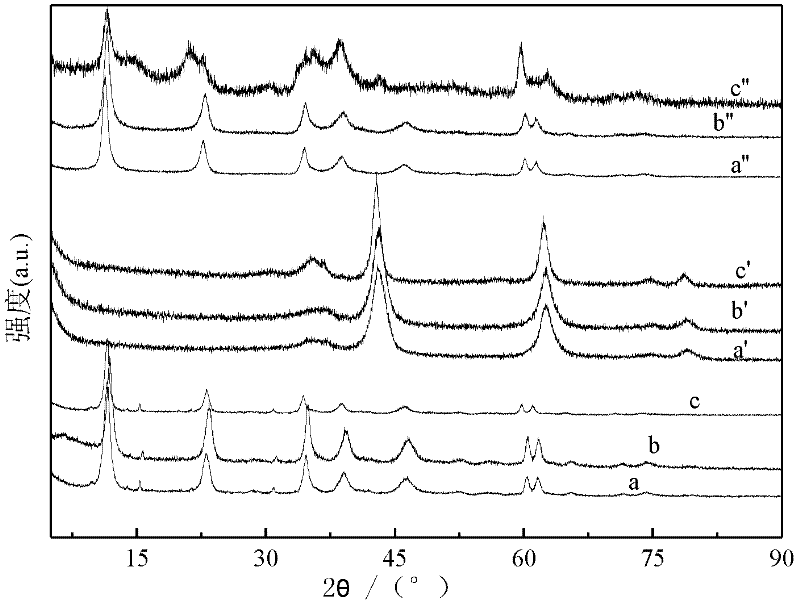

[0058] (2) Repeat steps (1) to (8) in Example 1. The magnesium-aluminum-iron ternary hydrotalcites [Mg 3 Al 0.6 Fe 0.4 (OH) 16 ]CO 3 4H 2 O (see its XRD spectrum figure 1 ) and calcined magnesium-aluminum-iron ternary hydrotalcite-like Mg 3 Al 0.6 Fe 0.4 o 9 .

[0059] (3) measured [Mg 2+ ] / [Al 3+ ] / [Fe 3+ ]=3:0.6:0.4, the removal rate of adsorbent to perchlorate was 88.92%.

Embodiment 3

[0061] (1) Repeat steps (1) to (6) in Example 1.

[0062] (2) Configuration series of perchlorate initial concentration is 2000μg / L, pH value is respectively 200mL of solution of 2, 4, 6, 8, 10, 12, and drops into 0.2g adsorbent respectively (adsorbent and solution mass ratio is 1 : 1000), put it into a shaker at 25°C at normal temperature, rotate at 200rpm, and vibrate for 12h, then get 5mL of the adsorption solution to filter through a 0.45μm filter membrane, and measure the adsorption rate of perchlorate by ion chromatography.

[0063] (3) The perchlorate removal rates of adsorbents for pH values of 2, 4, 6, 8, 10, and 12 were 28%, 90.65%, 90.89%, 88.29%, 88.75%, and 33.80%, respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com