Advanced treatment method for beta-naphthol wastewater

A technology for advanced treatment of waste water, applied in the field of chemical treatment, can solve the problems of low concentration of suspended solids, high operating costs, high cost of chemicals, etc., achieve strong corrosion resistance, good treatment effect, and increase the effect of surface-to-body ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

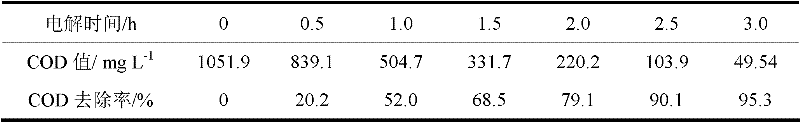

[0025] Two 2×5cm DSA electrodes are used as anodes, a stainless steel sheet of the same size is used as cathodes, and the distance between electrodes is 1cm. Electrochemical oxidation is used to treat β-naphthol wastewater with a COD of 1051.9mg L -1 , pH is 10 (original water sample pH), adding 1.0wt.% Na 2 SO 4 Supporting electrolyte with a current density of 25mA cm -2 , The reaction lasted 3h. Samples were taken from the reactor every 0.5h to analyze the UV-Vis and COD values. The experimental results are shown in Table 1. It can be seen from the results that when the reaction lasted for 2 hours, the gradient of the absorption peak in the ultraviolet spectrum decreased not obviously, and the removal rate of COD did not change much, so the reaction time was selected as 2 hours.

[0026] Table 1 Changes in COD of electrochemical advanced treatment of β-naphthol wastewater at different times

[0027]

Embodiment 2

[0029] Two 2×5cm DSA electrodes are used as anodes, a stainless steel sheet of the same size is used as cathodes, and the distance between electrodes is 1cm. Electrochemical oxidation is used to treat β-naphthol wastewater with a COD of 1051.9mg L -1 , pH is 9, adding 1.0wt.% Na 2 SO 4 supporting electrolyte with a current density of 20mA cm -2 、25mA cm -2 、30mA cm -2 、35mA cm -2 and 40mA cm -2 , The reaction lasted 2h. In the experimental results, we found that their corresponding COD values are 256.9mg L -1 , 220.2 mg L -1 , 177.3mg L -1 , 156.5mg L -1 and 139.8 mg L -1 . When the current is 30mA cm -2 , the COD removal rate has little change trend, so the current density is selected as 30mA cm -2 .

Embodiment 3

[0031] Two 2×5cm DSA electrodes are used as anodes, a stainless steel sheet of the same size is used as cathodes, and the distance between electrodes is 1cm. The electrochemical oxidation advanced treatment of β-naphthol wastewater, COD is 1124.4mg L -1 , pH were 3, 5, 7, 9 and 11 respectively, adding 1.0wt.% Na 2 SO 4 Supporting electrolyte with a current density of 30mA cm -2 , The reaction lasted 2h. In the experimental results, we found that their corresponding COD values are 230.3mg L -1 , 171.7mg L -1 , 191.5mg L -1 , 139.3 mg L -1 and 189.8mgL -1 . When pH=9, the COD removal rate is the highest under other conditions unchanged, so the optimum pH is chosen as 9.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com