Reactive-extrusion addition ethylene-propylene diene monomer rubber sulfonate and preparation method thereof

A technology of EPDM rubber and EPDM rubber, which is applied in the chemical industry, can solve the problems of low mechanical strength, unsatisfactory performance, poor processing performance, etc., and meet the diversified needs of the market and achieve excellent mechanical and mechanical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Recipe: Table 2

[0020] Formula material

Dosage (parts by weight)

EPDM

100

Initiator (DCP)

0.2~0.3

4~5

1~1.4

Antioxidant 1076

0.6

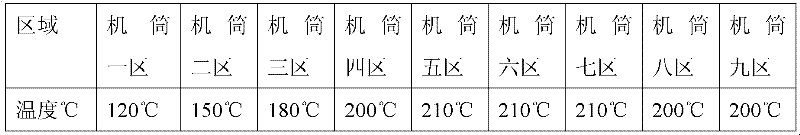

[0021] Implementation process: Stir EPDM rubber, initiator, nucleophile, processing aid and antioxidant in a high-speed mixer for 7 to 8 minutes, then add it to a twin-screw extruder with a screw speed of 100 rpm , the twin-screw extruder temperature settings are shown in Table 3:

[0022] table 3

[0023]

Embodiment 2

[0025] Recipe: Table 4

[0026] Formula material

Dosage (parts by weight)

EPDM

110

Initiator (DCP)

0.4

6

0.6

Antioxidant 1076

0.5

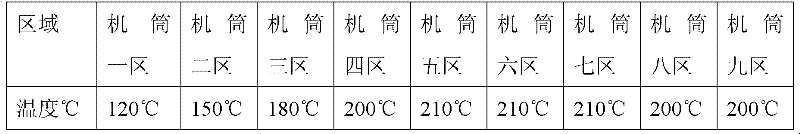

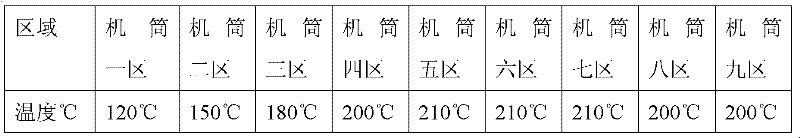

[0027] Implementation process: Stir EPDM rubber, initiator, nucleophile, processing aid and antioxidant in a high-speed mixer for 7 to 8 minutes, then add it to a twin-screw extruder with a screw speed of 100 rpm , the twin-screw extruder temperature settings are shown in Table 5:

[0028] table 5

[0029]

[0030] Table 6 is a performance comparison table of the reaction extrusion addition EPDM rubber sulfonated product of Example 1 of the present invention and ordinary EPDM rubber. From the comparative data in the table, it can be seen that the tensile strength and elongation at break of the sulfonated product of the present invention The rate and adhesion properties are significantly higher than the existing ordinary EPDM ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com