Ultraviolet resistant polyvinyl alcohol fruit bag film preparation formula and technology thereof

A polyvinyl alcohol and anti-ultraviolet technology, applied in the direction of plant protection covers, etc., can solve the problems of loss of anti-ultraviolet, small air flow, easy deformation, etc., achieve strong anti-ultraviolet, easy to deform when exposed to water, and small air flow , The effect of preventing photodegradation

Inactive Publication Date: 2012-06-20

郝喜海

View PDF1 Cites 17 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

This polyvinyl alcohol film is easily deformed when exposed to water, and has a small air permeability, which greatly limits the application range of water-soluble films in the market, especially for outdoor use or applications that require high air permeability.

[0004] In addition, when used as fruit bagging, etc., the UV absorption rate of polyvinyl alcohol film is an important indicator that affects its use value. The special publication No. 51-132259 reported adding water-soluble UV absorbers to polyvinyl alcohol films. However, this polyvinyl alcohol film with a water-soluble ultraviolet absorber has a high ultraviolet absorption rate, and the disadvantage is that when the film is stored for a long time, the ultraviolet absorber is precipitated, thereby affecting the long-term preservation of the polyvinyl alcohol film. UV absorption rate; and the Japanese open-ended No. 98-123410 communiqué has reported the method of adding an organic UV absorber to the polyvinyl alcohol film, but the shortcoming of this method is that the organic anti-UV agent will gradually decomposes, thereby losing its UV-resistant properties

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

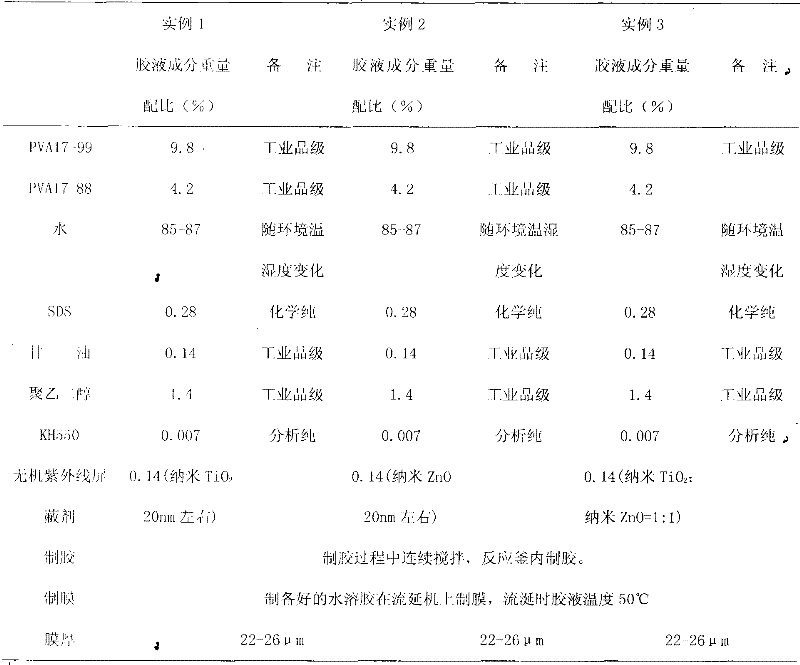

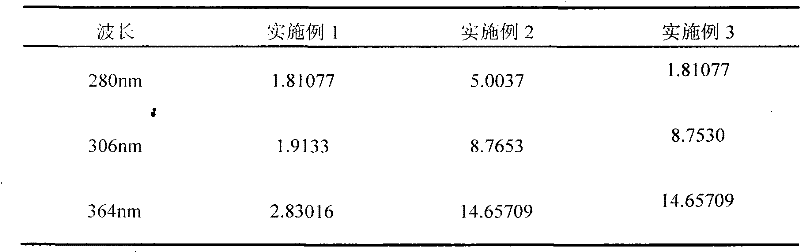

The invention provides an ultraviolet resistant polyvinyl alcohol fruit bag film preparation formula and technology thereof, and the invention uses partial alcoholysis type polyvinyl alcohol, complete alcoholysis type polyvinyl alcohol and an inorganic ultraviolet ray screener as main raw materials, and a plasticizer, a surfactant, an emulsifier, etc. are added for mixing and preparing rubber, and a solution tape casting method is used for preparing a film. The ventilating amount of the composite film is regulated by adjusting the proportion of the partial alcoholysis type polyvinyl alcohol in a film forming agent; the ultraviolet resistance performance is realized by the inorganic ultraviolet ray screener nanometer titanium dioxide or nanometer zinc oxide or a combination thereof. The intensity of ultraviolet resistance can be set freely according to the requirement of users. The ultraviolet resistant polyvinyl alcohol fruit bag film of the invention is made of the polyvinyl alcohol-containing film which has the advantages of biological degradability, ultraviolet resistance, high permeability, anti-softening with water, etc., and is especially suitable for preparing fruit plastic film bags and automobile glass, etc.

Description

technical field [0001] The invention relates to a preparation formula and process of an anti-ultraviolet polyvinyl alcohol fruit bag film. Ultraviolet strong polyvinyl alcohol composite film and its preparation process. Background technique [0002] At present, polyethylene (PE) is generally used as the main material for fruit plastic film bags on the market. This PE film cannot be completely degraded and will cause serious pollution to the environment. The country has banned its use, while PVA (polyethylene) Alcohol) film material has 100% biodegradability, is a green packaging material, and its environmental protection is recognized in Europe, America and other countries, and its application fields are allowed and widely promoted. my country is a big producer of polyvinyl alcohol, which has absolute advantages in all aspects. Therefore, using PVA film instead of PE film to produce fruit bagging can not only solve the problems of environmental protection and poor fruit qua...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08L29/04C08K13/06C08K9/06C08K3/22C08K5/053A01G13/02C08J5/18

Inventor 郝喜海李慧敏

Owner 郝喜海

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com