Fingerprint pollution preventing transparent hardening film

A hardened film and anti-fingerprint technology, applied in the field of film materials, can solve the problems of losing dust and anti-fingerprints, and achieve the effects of preventing fingerprint pollution, reducing surface tension, and lasting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

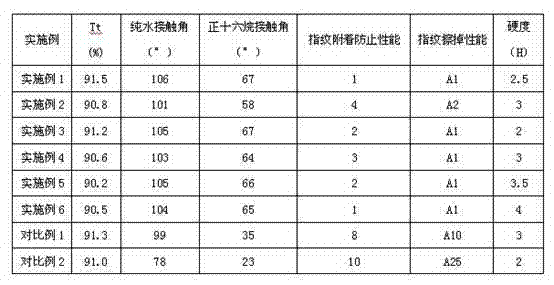

Examples

Embodiment 1

[0044] B-530 UV 55.0 parts,

[0045] DPHA 5.0 parts,

[0046] Modified perfluoropolyether DAC-HP 2.0 parts,

[0047] Photoinitiator 1173 15.0 parts,

[0048] Levaslip 432 0.05 parts,

[0049] 20.5 parts of mixed solvent,

[0050] To 55 parts by weight of polyester acrylate prepolymer B-530 UV (manufactured by Guangzhou Boxing Chemical Technology Co., Ltd., functionality 4, average molecular weight of 2500) and 5.0 parts by weight of dipentaerythritol pentaacrylate resin-DPHA (Tianjin Tianjiao Chemical Co., Ltd., functionality 5, molecular weight 524), add 2 parts by weight of modified perfluoropolyether DAC-HP (solid component concentration: 20%) (manufactured by Daikin Corporation of Japan), and add 15.0 parts by weight Photoinitiator [manufactured by Nanjing Jiean Chemical Co., Ltd.; 1173] and 0.05 parts by weight of a leveling agent with a polydimethylsiloxane skeleton structure [manufactured by Deqian (Shanghai) Chemical Co., Ltd.; trade name: Levaslip 432]. Dilute t...

Embodiment 2

[0053] 6230 15.0 copies,

[0054] PETA 35.0 parts,

[0055] Modified perfluoropolyether DS-710ZLC 0.2 part,

[0056] Photoinitiator 1173 2.0 parts,

[0057] Levaslip 433 0.3 parts,

[0058] 47.5 parts of mixed solvent,

[0059] To 15 polyester acrylate prepolymer 6230 (manufactured by Changxing Chemical Industry Co., Ltd., functionality 5, average molecular weight 1000) and 35.0 parts by weight of pentaerythritol triacrylate PETA (manufactured by Tianjin Tianjiao Chemical Co., Ltd., functionality 3, average molecular weight 298), 0.2 parts by weight of modified perfluoropolyether DS-710ZLC (solid component concentration: 20%) [manufactured by Harves Corporation of Japan] was added. Add 10 parts by weight of a photoinitiator [manufactured by Nanjing Jiean Chemical Co., Ltd.; 1173] and 0.3 parts by weight of a leveling agent with a polydimethylsiloxane skeleton structure [manufactured by Deqian (Shanghai) Chemical Co., Ltd. ; trade name: Levaslip 433]. Dilute the resulting...

Embodiment 3

[0062] HM-336A 25.0 parts,

[0063] TMPTA 20.0 parts,

[0064] SOILNON AF-01 1.0 parts,

[0065] Photoinitiator 184 3.0 parts,

[0066] BYK377 0.5 parts,

[0067] 50.5 parts of mixed solvent,

[0068] Add 25 parts by weight of polyester acrylate prepolymer HM-336A (manufactured by Jiangxi Kunlong New Material Co., Ltd., functionality 3, average molecular weight 1500) and 20.0 parts by weight of trimethylolpropane triacrylate TMPTA (manufactured by Tianjin Tianjiao Chemical Co., Ltd., functionality 3, average molecular weight 296), add 1.0 parts by weight of modified perfluoropolyether SOILNON AF-01 [manufactured by Nichika Corporation; SOILNON AF-01]. Add 3.0 parts by weight of photoinitiator [manufactured by Nanjing Jiean Chemical Co., Ltd.; 184] and 0.5 parts by weight of a leveling agent with a polydimethylsiloxane skeleton structure [manufactured by BYK Chemicals; trade name: BYK 377]. Dilute the resulting mixture with 50.5 parts by weight of a mixed solvent comprisi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com