Automobile bi-component intermediate paint resistant to rock impact

A kind of anti-stone impact, two-component technology, applied in the field of automotive paint in the field of paint making technology, can solve the difficult to meet the requirements of impact resistance, the hardness of the coating film is difficult to meet the requirements of the coating process, and it is difficult to meet the acid and alkali resistance Grinding performance and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] 1. Weigh 850Kg of soft polyisocyanate resin and 100Kg of hard polyisocyanate resin of component A, add 50Kg of butyl acetate as a solvent into a clean and dry stainless steel tank, stir evenly at a medium speed (500-800rmp), and pass the inspection Filter, replace the air in the packaging barrel with nitrogen and then pack.

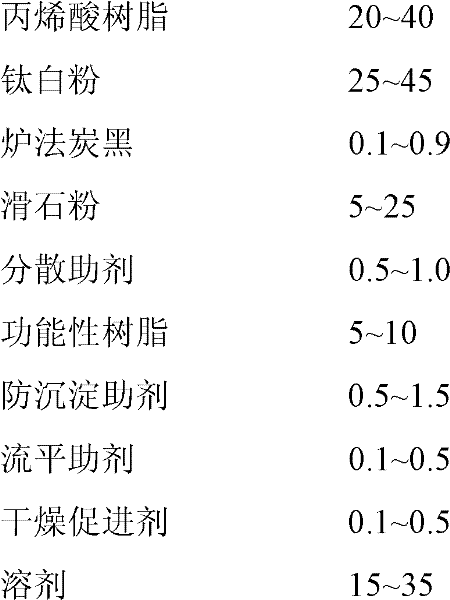

[0066]2. Take by weighing 220Kg of acrylic resin of the second component, 5Kg of hydrogenated castor oil as anti-precipitation aid (anti-precipitation effect), 350Kg of titanium dioxide as coloring pigment, 2Kg of furnace carbon black as coloring pigment, as filler Superfine talcum powder 120Kg, BYK-163 3Kg as a dispersing aid, butyl acetate as a solvent and 300Kg of DBE solvent (total weight 1000Kg) are mixed and stirred evenly, dispersed with a sand mill until the fineness is below 20μm, and transferred to the paint In the cylinder, add 50Kg of functional resin bisphenol F epoxy resin, 5Kg of dibutyltin as a drying accelerator (drying acceleratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com