Ground crosslinked acid liquid for acid fracturing and preparation method thereof

A technology of cross-linking acid and ground, applied in chemical instruments and methods, earthwork drilling, drilling composition, etc., can solve the problems of unstable cross-linking agent and precipitation, etc. High viscosity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

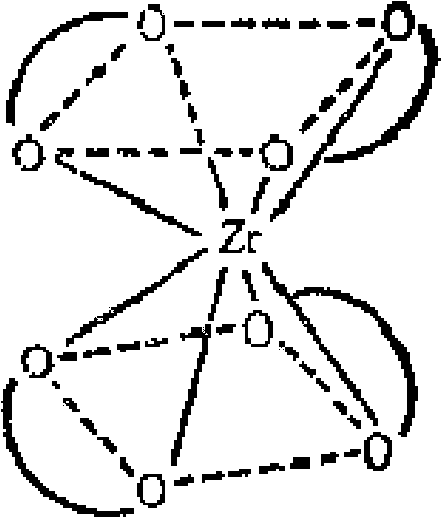

[0031] Embodiment 1: the synthesis of zirconium acetylacetonate

[0032] Dissolve 12.0g of zirconium oxychloride in 15.0g of distilled water, stir until completely dissolved, pour it into a four-necked reaction flask equipped with a reflux condensation device, raise the temperature to 50°C±1°C, then add 15.0g of acetylacetone and ethylene glycol Aldehyde 1.0g, react for 4.0h, heat up to 80°C±1°C, continue to react for 1h to obtain zirconium acetylacetonate.

Embodiment 2

[0035] Embodiment 2: ground cross-linking acid solution, by mass percentage component is as follows:

[0036] Concentrated hydrochloric acid 55.6% (equivalent to 20% of pure hydrogen chloride), thickener 1.0%, organometallic crosslinking agent 4.0%, and the rest is water.

[0037] Preparation of ground cross-linking acid solution: Add 39.4 parts of water, 55.6 parts of concentrated hydrochloric acid and 1.0 part of thickener in order by mass parts, stir evenly and add 4.0 parts of freshly prepared organometallic cross-linking agent zirconium acetylacetonate.

[0038] The cross-linking time of the ground cross-linking acid solution of the present embodiment is 4.0min (30 DEG C), after cross-linking, form a colorless transparent jelly that can be hung (see attached figure 1 ), at 140℃, 170S -1 Conditional shear 0.5h, viscosity 126mPa.s. The sedimentation velocity of quartz sand is 0.0055cm / s.

Embodiment 3

[0040] As described in Example 2, the difference is that the organometallic crosslinking agent zirconium acetylacetonate prepared in Example 1 was used after standing for 50 days. After being placed for 50 days, the zirconium acetylacetonate was clear without precipitation. The crosslinking time of the ground crosslinking acid solution was 4.1min (30°C), and a jelly that could be hung was formed after crosslinking. Performance is unchanged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com