Soil conditioning agent

A soil conditioner and soil technology, applied in the direction of soil conditioning materials, organic fertilizers, fertilizer mixtures, etc., can solve the problems of reducing arsenic absorption, arsenic absorption performance, low production cost, poor application effect, etc., to achieve strong adsorption and immobilization Ability to reduce arsenic absorption and reduce toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

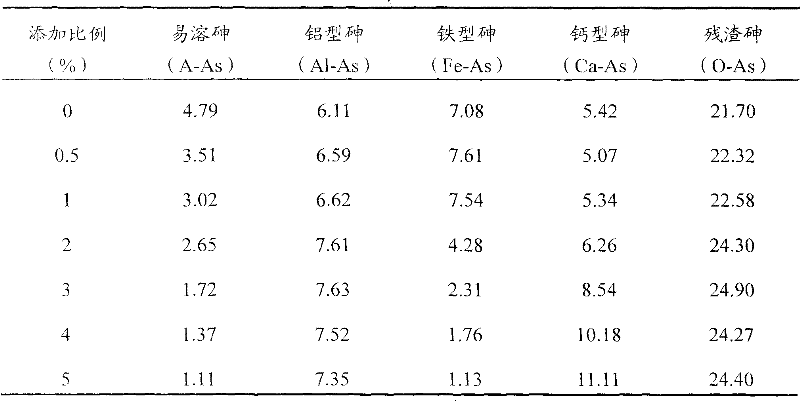

[0022] The soil conditioner provided by the invention comprises: 55% to 65% of magnesium and aluminum double metal oxides, 20% to 30% of straw biomass coke and 10% to 20% of iron phosphate.

[0023] In the above embodiments, 20%-30% of the biomass coke is produced by carbonizing 40-50% of crop straw (such as rice, millet or corn straw).

[0024] In the above embodiments, 55% to 65% of magnesium and aluminum bimetallic oxides are obtained through 55% to 65% of finely ground magnesium aluminum hydrotalcite (hereinafter referred to as hydrotalcite).

Embodiment 2

[0026] The method embodiment of preparing above-mentioned soil conditioner, comprises the steps:

[0027] According to the calculation of the soil conditioner with a total weight of 100 kg, the following materials are weighed: 55 kg of ground magnesium aluminum hydrotalcite, 45 kg of ground corn stalks, 20 kg of ground iron phosphate; the weighed materials are evenly mixed, and Wet it with water until water can come out when grasping it, forming a mixed material;

[0028] Cover the mixed material with a plastic film, and stack it indoors for 3 to 4 days, then place it in a carbonization furnace, heat the mixed material slowly to 490°C in a relatively sealed state, and keep it for 2.8 hours, then stop heating, and let the carbonization process slowly The heated mixed material is taken out after gradually cooling, ground and passed through a 0.20mm sieve to obtain the soil conditioner of the present invention.

Embodiment 3

[0030] The method embodiment of preparing above-mentioned soil conditioner, comprises the steps:

[0031] According to the calculation of the soil conditioner with a total weight of 100 kg, the following materials are weighed: 60 kg of ground magnesium aluminum hydrotalcite, 50 kg of ground corn stalks, 10 kg of ground iron phosphate; the weighed materials are evenly mixed, and Wet it with water until water can come out when grasping it, forming a mixed material;

[0032] Cover the mixed material with a plastic film, and stack it indoors for 3 to 4 days, then place it in a carbonization furnace, heat the mixed material slowly to 500°C in a relatively sealed state, and keep it for 3 hours, then stop heating, and let the carbonization process slowly The heated mixed material is taken out after gradually cooling, ground and passed through a 0.25mm sieve to obtain the soil conditioner of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com