Anti-itchy finishing method for ramie fabric

A technology for itching and weaving, which is applied in the field of anti-itching finishing of ramie fabrics, can solve the problems that the rigidity of ramie fibers cannot be directly reduced, the effect of anti-itching effect is not significant, and the strength of ramie fabrics is lost, so as to reduce the itching of fabrics and improve wearability. performance, rigidity reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

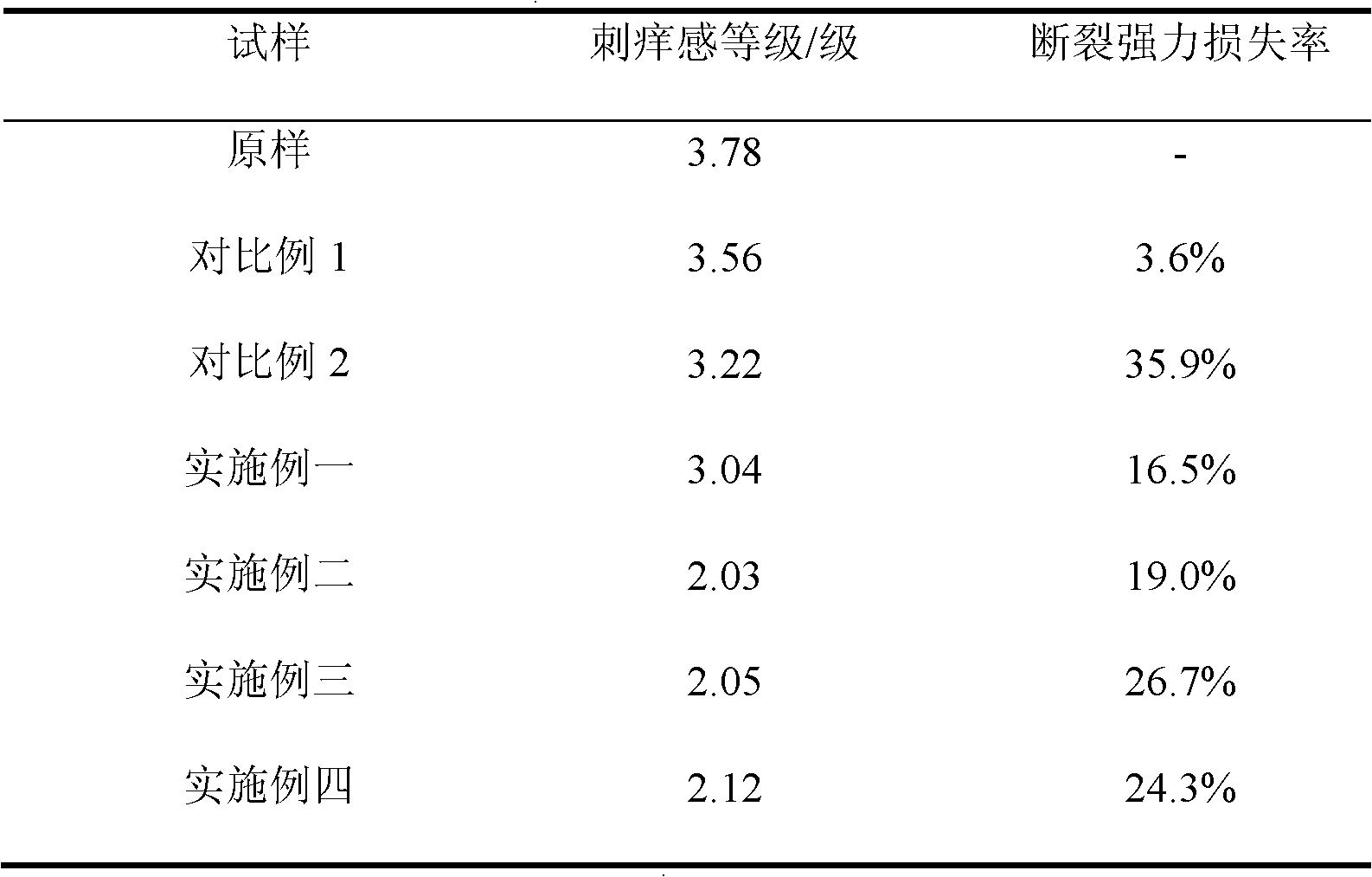

Embodiment 1

[0031] In this example, cellulase 80L and water-based polyurethane finishing agent PA-11 were used to jointly finish the ramie fabric. The specific operation steps are as follows:

[0032] (1) Cellulase finishing of ramie fabric

[0033] Finishing solution formula: 80L cellulase dosage is 1.0% (o.w.f.), bath ratio is 1:30.

[0034] Finishing process: configure a buffer solution with a pH of 4.5, bathe the fabric at room temperature, add cellulase when the temperature rises to 55°C, keep warm for 90 minutes, take the fabric out and treat it in hot water at 100°C for 10 minutes to make the fibers Sulfase is completely inactivated, take it out, wash it with water, and dry it in the air.

[0035] (2) Polyurethane finishing of ramie fabric

[0036] Finishing liquid formula: the dosage of polyurethane finishing agent PA-11 is 40g / L.

[0037] Finishing process: the fabric after the cellulase finishing in step (1) is dipped twice in the polyurethane finishing solution at room temp...

Embodiment 2

[0039] In this example, cellulase 80L and water-based polyurethane finishing agent PA-11 were used to jointly finish the ramie fabric. The specific operation steps are as follows:

[0040] (1) Cellulase finishing of ramie fabric: same example one.

[0041] (2) Polyurethane finishing of ramie fabric

[0042] Finishing solution formula: the dosage of polyurethane finishing agent PA-11 is 140g / L.

[0043] Finishing process: the fabric after cellulase finishing in step (1) is dipped twice in polyurethane finishing solution at room temperature, the liquid retention rate is 100%, pre-baked at 80°C for 3 minutes, and then heated at 150°C Bake at ambient for 6 minutes.

Embodiment 3

[0045] In this example, cellulase 80L and water-based polyurethane finishing agent PA-11 were used to jointly finish the ramie fabric. The specific operation steps are as follows:

[0046] (1) Cellulase finishing of ramie fabric: same example one.

[0047] (2) Polyurethane finishing of ramie fabric

[0048] Finishing liquid formula: the dosage of polyurethane finishing agent PA-11 is 200g / L.

[0049]Finishing process: the fabric after cellulase finishing in step (1) is dipped twice in polyurethane finishing solution at room temperature, and the liquid retention rate is 98%, pre-baked at 75°C for 4 minutes, and then heated at 180°C Bake at ambient for 5 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com