Combined device of solid-phase micro-extraction and electrochemical sensor and single chip microcomputer

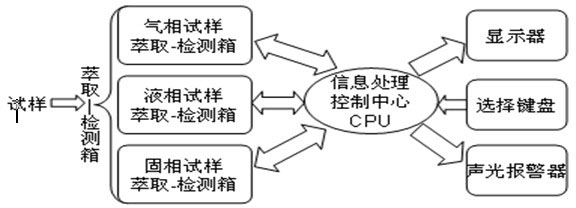

A sensor and electrochemical technology, which is applied in the field of solid-phase microextraction, electrochemical sensors and single-chip microcomputer combined devices, can solve the problems of easy interference and short working life of electrochemical sensors, and achieves low cost, high speed, and easy to overcome problems. disturbed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

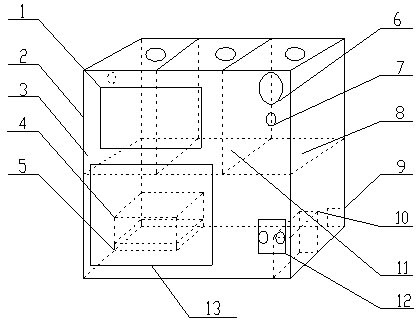

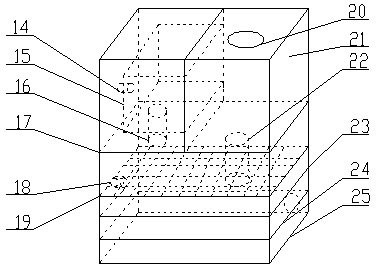

[0034] Example 1 Gas phase sample extraction-detection process

[0035] As shown in accompanying drawing 3, during gas phase sample detection, gas sample is first sucked into gas storage chamber 15 by gas pump 14, then enters solid phase microextraction chamber 17 by quantitative autosampler 16, and gas sample is passed through solid phase micro The extraction head integration plate 19, the extracted gas is discharged through the air pump 18. According to the signal sent by the gas sensor, the CPU4 makes an instruction for the desorption liquid adder 22 to work to perform the desorption work. The desorption liquid is stored in the liquid storage chamber 21 , and the liquid storage chamber 21 is connected with the desorption liquid adder 22 . After the desorption is completed, the desorbed sample enters the electrochemical sensor detection tank 24 through the desorption liquid collection tank 23 for detection. After the CPU4 processes the sensor detection signal, the result i...

Embodiment 2

[0039] Example 2 Liquid Phase Sample Extraction-Detection Process

[0040] As shown in Figure 12, when the liquid phase sample is tested, the liquid phase sample enters the liquid storage chamber 43 from the sample inlet 42, and then flows into the solid phase microextraction chamber 45 through the liquid sample conduit 44. After the extraction is completed, the liquid sample is discharged through the liquid sample outlet 50 . The desorption liquid is added into the desorption liquid storage chamber 48 from the desorption liquid addition port 47 . There is a manual switch 52 at the bottom of the waste liquid recovery tank 46 .

[0041] As shown in Figure 13, the liquid storage chamber 43 is provided with a stirrer 41, which is located at the upper left of the solid phase microextraction chamber 45 and communicates with the solid phase microextraction chamber 45 through a liquid sample conduit 44. The desorption liquid adder 49, the solid phase microextraction chamber 45,...

Embodiment 3

[0042] Example 3 Solid-phase sample extraction-detection process

[0043] As shown in accompanying drawing 14, when the volatile component in the solid-phase sample is detected, the solid-phase sample is put into the volatilization chamber 62 from the right side port 61, after closing the valve, after connecting the solid-phase sample detection switch, the volatile component Volatile when heated. The volatile components enter the solid phase microextraction chamber 58 after being condensed by the condenser tube 55 . The desorption liquid is added into the desorption liquid storage chamber 56 from the desorption liquid addition port 54 . After the extraction was completed, the CPU4 gave an instruction, and the desorption liquid adder 57 started to work. The extracted liquid is discharged through the liquid sample outlet 63 . The volatilization chamber 62 is located at the upper right of the SPME chamber 58 and has a heating resistance wire 67 at the bottom. The condensation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com