Automatic detection device of leakage rays in X-ray protective system

A protection system, X-ray technology, applied in the direction of radiation measurement, use feedback control, instruments, etc., to achieve the effects of high detection accuracy, precise positioning, and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The structure of the present invention is illustrated in conjunction with the accompanying drawings.

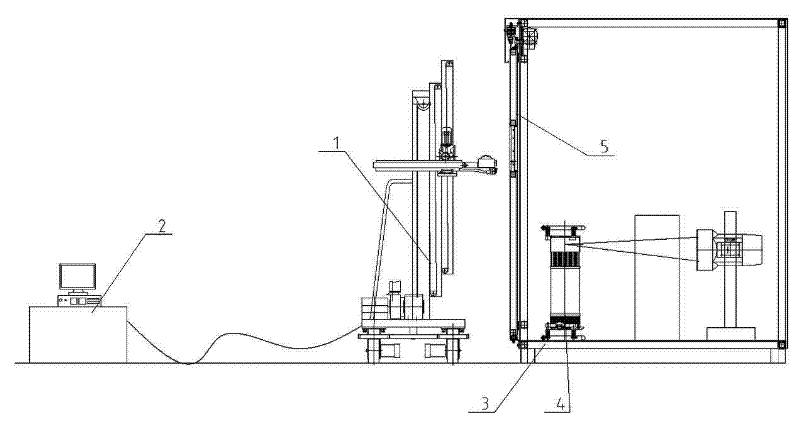

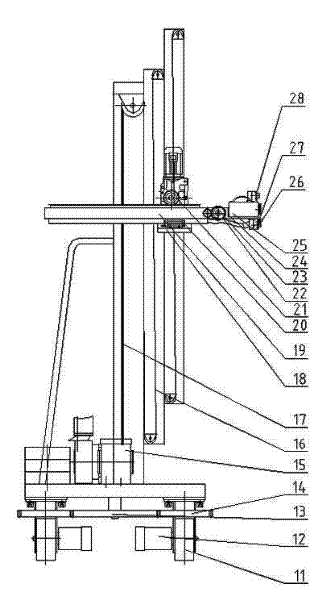

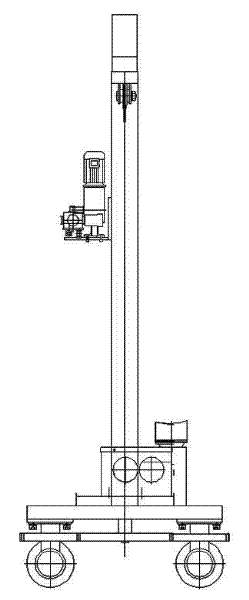

[0011] An automatic detection device for leakage rays in X-ray protection, such as figure 1 As shown, the automatic detection frame trolley 1 is placed near the shielded and protected lead chamber 3 that needs to be detected. Connect to the remote control center. Turn on the X-ray machine system 4 in the shielded and protected lead room 3 to the maximum power working state for irradiation. After the automatic control carriage reaches the standard detection position, the leak detection starts. The detection result data is stored synchronously through real-time monitoring and synchronous feedback. According to the special position and key position of the shielding protection room, such as the side seam interface of the lead door 5 of the shielding protection room, adjust the height, position and angle of the detection instrument, and perform all-round detection of lea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com