Coupling peak absorption circuit at input end of motor

A technology of peak absorption and input terminal, applied in the field of motor control, can solve the problems of difficult to eliminate peak voltage pulses, large heat generation in the filter circuit, and increase the loss of high frequency energy of the fundamental wave. wildcard effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

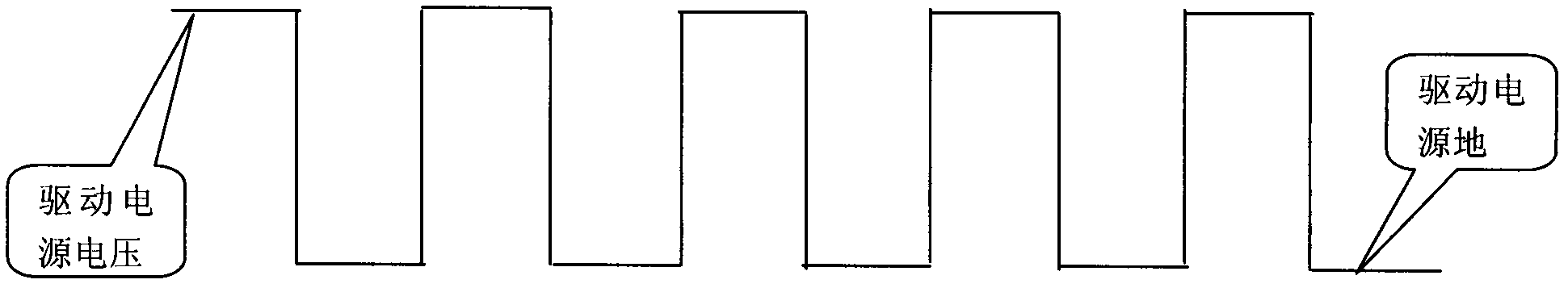

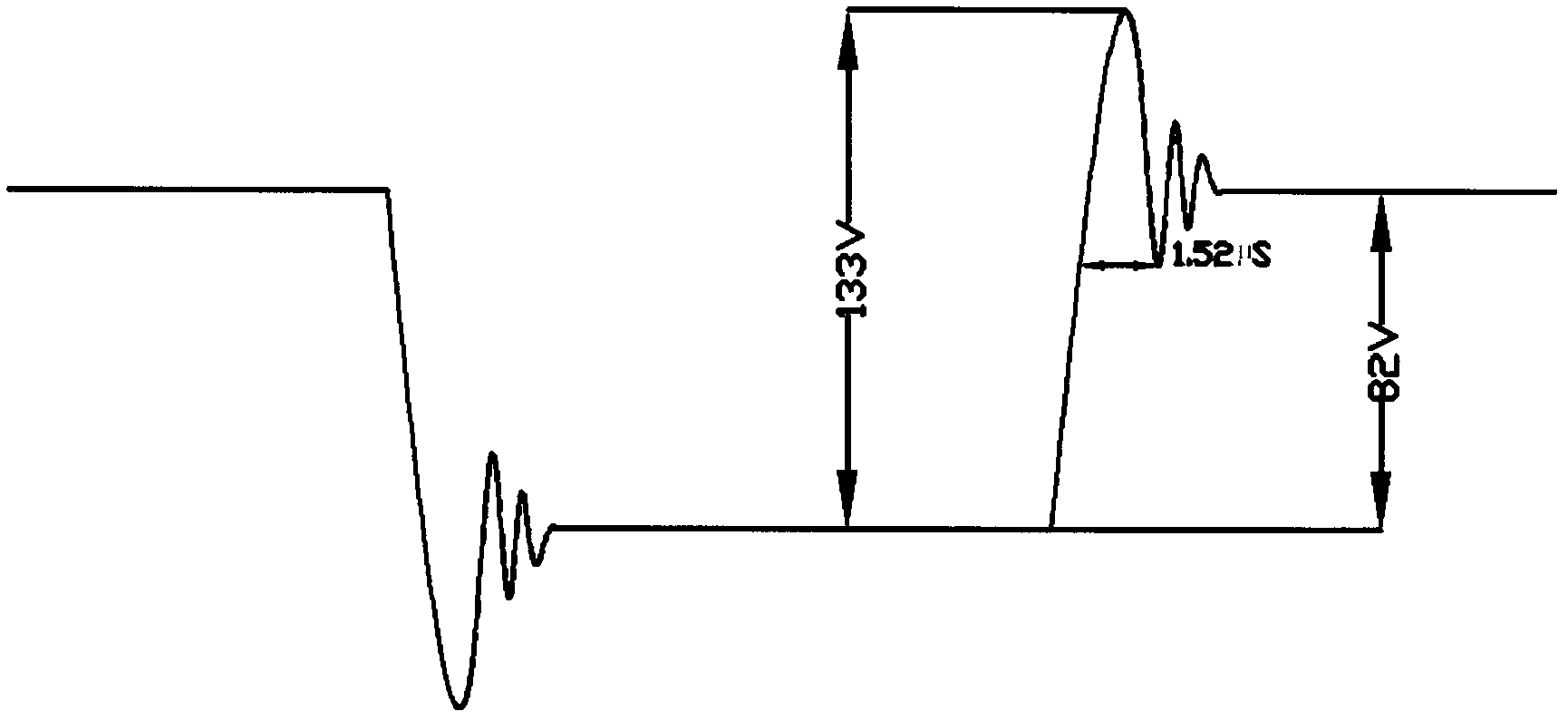

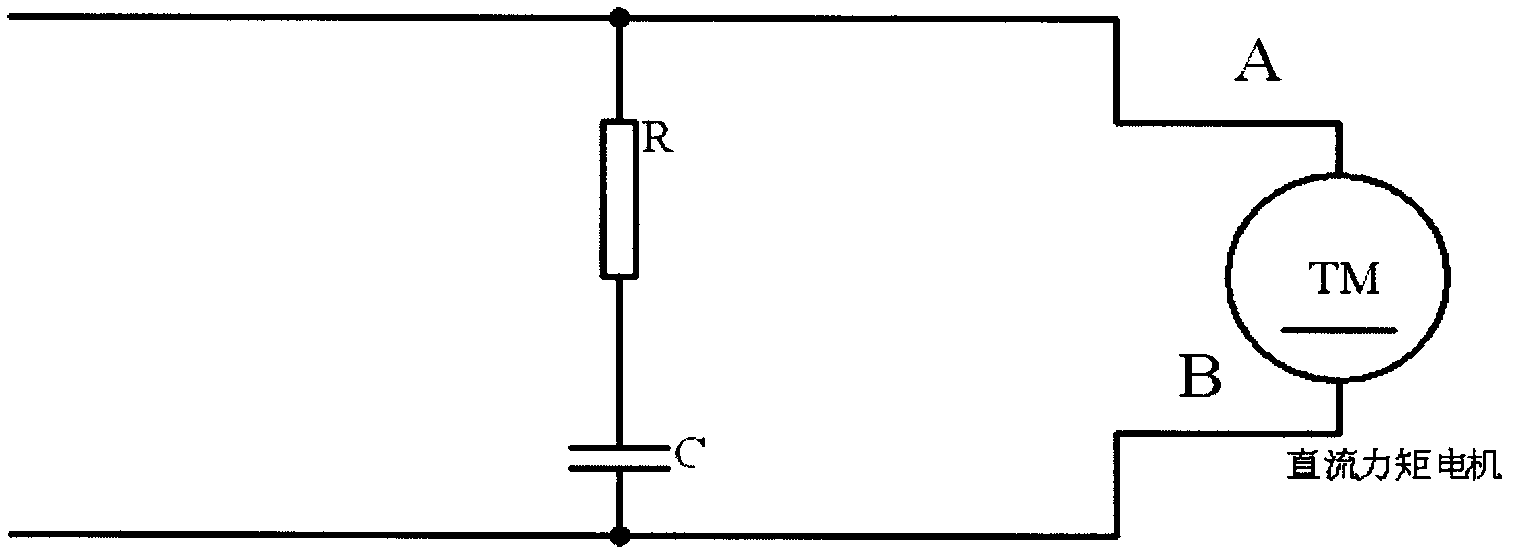

[0020] For a certain type of photoelectric turntable that uses PWM to drive the torque motor, its drive unit is about 55 meters away from the torque motor. When the photoelectric turntable has been used for one year, the insulation layer of the torque motor is broken down and the motor is damaged, and the two ends of the motor produce such figure 2 The voltage waveform shown, that is, coupled spikes are the main cause of torque motor reliability degradation. In order to solve the reliability problem of the torque motor, and avoid the side effects brought by the RC / LRC filter circuit on the photoelectric turntable. Therefore, the applicant considers adding a coupling peak absorbing circuit based on a fast recovery diode between the motor drive unit and the torque motor, and directly absorbs the coupling peak pulse at the input end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com