Efficient method for coating tail gas clean-up three-way catalyst

A three-way catalyst and exhaust gas purification technology, applied in physical/chemical process catalysts, chemical instruments and methods, catalyst activation/preparation, etc., can solve the problems of single exhaust gas control, high production cost, low production efficiency, etc. The effect of exhaust gas control function, improving production efficiency, and reducing the pressure of installation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

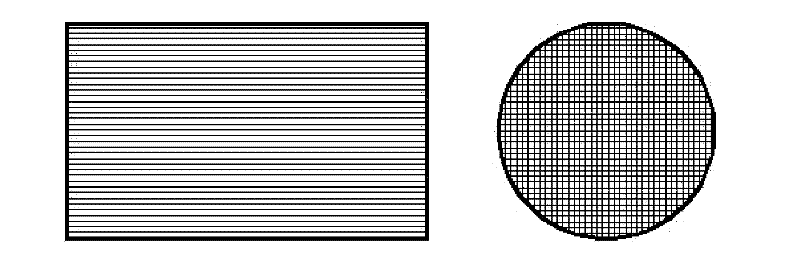

Image

Examples

Embodiment approach 1

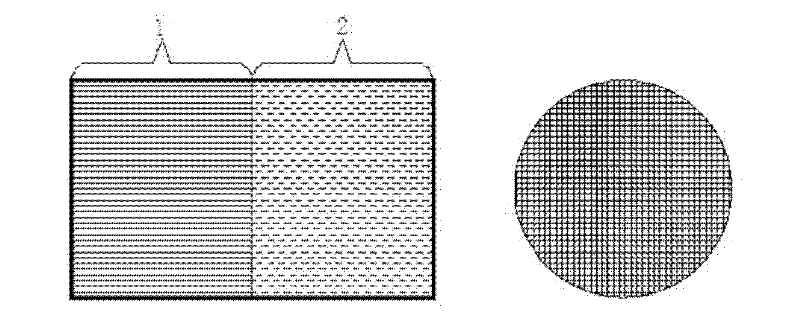

[0030] like image 3 Shown is a schematic diagram of the two-stage coating structure, the first coating 1 covers the half of the carrier at the upstream end of the exhaust gas flow, and the second coating 2 covers the half of the carrier at the downstream of the gas flow. After the first coating 1 is coated, the second coating 2 is applied, and then baked at a temperature of 500-600 degrees Celsius. In order to achieve the required coating load, the first coating 1 and the second coating are repeated. Layer 2 is applied and baked into shape. The catalyst raw materials, catalytic element concentrations and formulations used in the upstream and downstream coatings of the coating carrier are different, which need to be adjusted according to the emission characteristics of specific models. This makes it possible to obtain completely different catalytic properties in the axial direction of the support (airflow direction), greatly increasing the design scope and flexibility of mode...

Embodiment approach 2

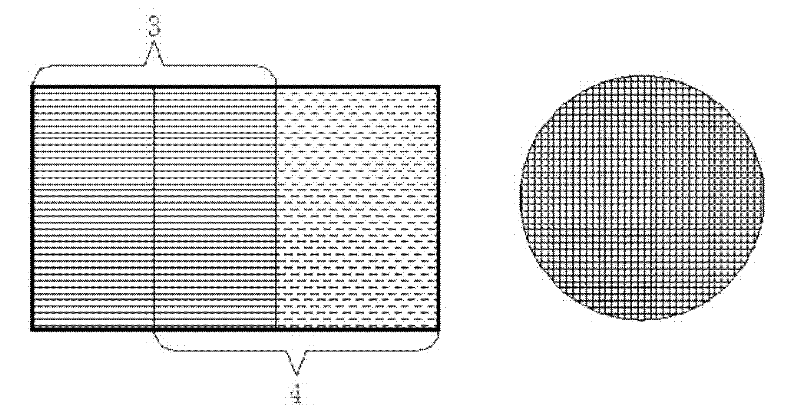

[0032] like Figure 4 Shown is a schematic diagram of the two-stage overlapping coating structure. The third coating 3 covers a large half of the carrier at the upstream end of the exhaust gas flow, and the fourth coating 4 covers a large half of the carrier downstream. Therefore, the middle section can have an overlapping coverage area. The specific coverage The length of the segment can be determined according to the exhaust gas control requirements. In this way, three different coating catalytic properties are actually formed along the axis of the carrier.

Embodiment approach 3

[0034] As shown in Figure 5, it is a schematic diagram of the three-stage three-stage coating structure. The coating method of the fifth coating 5 and the sixth coating 6 is similar to that of Embodiment 1, and the fifth coating 5 and the sixth coating 6 are coated. After firing, the seventh coating layer 7 is applied, and the seventh coating layer 7 covers most of the carrier at the upstream or downstream end. In this way, catalyst formulation coating materials with three different catalytic strategies can actually be used, and the functions of oxidation and reduction in the three-way catalyst can be optimally combined, and catalysts for special purposes (such as gasoline direct injection ignition engines) can also be used The NOxadsorber technology in GDI) is introduced into the single-support catalyst design, which brings great flexibility to the design.

[0035] The above-mentioned embodiment is just an example to help understanding of the present invention, and the presen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com