Device for screening powder by convoluted air flow

A technology of airflow sieve and sampling sieve, which is applied in the direction of sieving, separating solids from solids with airflow, solid separation, etc. It can solve problems such as dust pollution, blockage of screens, and influence of drug sieving rate. Convenient and easy to replace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

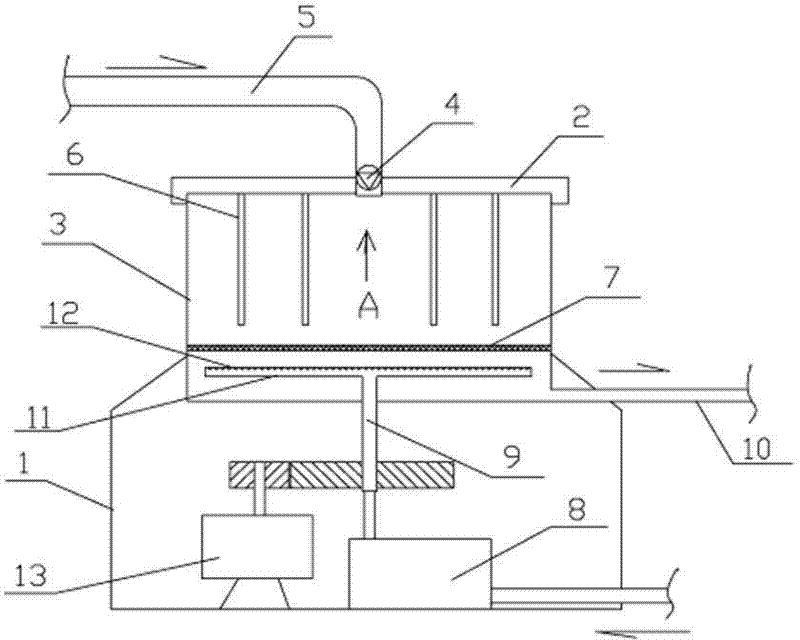

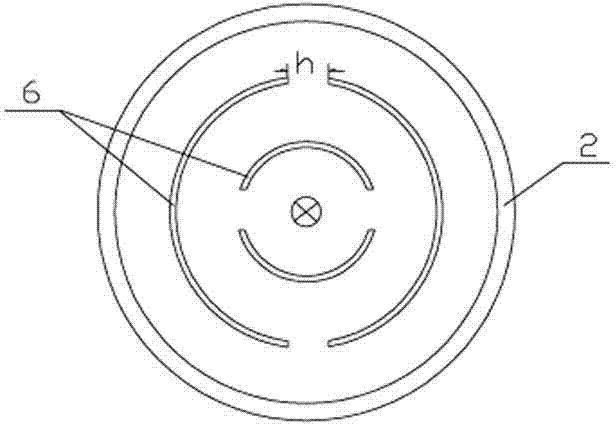

[0012] Such as figure 1 , 2 As shown, the whirling air flow sieving device of the present invention includes a base 1 and a sieving chamber 3 provided on the base 1 with a sealed upper cover 2 and a powder inlet opening on the sealed upper cover 2. The port is communicated with the external powder inlet channel 5 through the control valve 4, and the control valve 4 controls the powder intake according to the needs; two sets of double arc partitions 6 are arranged concentrically on the inner side of the upper seal cover 2, two arc partitions with the same radius The distance h between the plates 6 is 2cm; a sample sieve 7 is horizontally arranged in the powder sieve chamber 3, and the size of the sample sieve 7 can be changed as needed; an air filter 8 is arranged in the lower part of the base 1 The air inlet of the filter 8 is in communication with the atmosphere, and the air outlet pipe 9 connected to the air outlet of the air filter 8 extends from the bottom of the powder siev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com