Medium temperature Zn-Al solder containing Sr, Si, Ti, Ni and P and having high air tightness

A high airtight, zn-al technology, applied in the direction of welding/cutting media/materials, welding media, metal processing equipment, etc., can solve problems such as difficult brazing, high melting point, and inability to meet the mass production requirements of brazed joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

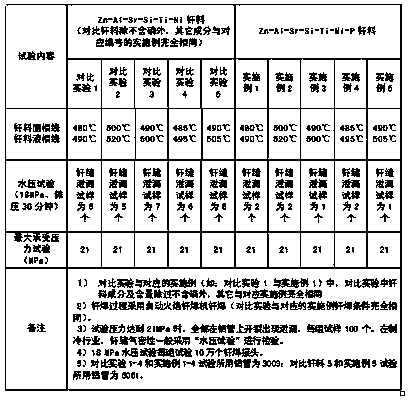

Examples

Embodiment 1

[0023] A medium temperature aluminum solder with high air tightness, its chemical composition is: 0.01% Sr, 6.5% Si, 0.001% Ti, 0.01% Ni, 0.0001% P, 65.0% Zn , the balance being Al.

[0024] The "medium temperature aluminum brazing filler metal with high airtightness" obtained by the above composition ratio, combined with commercially available CsF-AlF 3 Flux or KF-AlF 3 Brazing flux has excellent wettability and permeability on the surface of 3-series and 6-series high-strength aluminum alloys, excellent mechanical properties of brazing joints, and excellent air tightness. The brazed joints have passed the hydrostatic test (the water pressure is 18MPa and the pressure is maintained for 30 minutes), and the brazed joints have no leakage. The maximum pressure of the brazed joints in the hydrostatic test can reach 21 MPa (cracking at the aluminum tube).

Embodiment 2

[0026] A medium-temperature aluminum solder with high air tightness, its chemical composition is: 0.1% Sr, 1.5% Si, 0.01% Ti, 0.001% Ni, 0.001% P, 36.0% Zn , the balance being Al.

[0027] The "medium temperature aluminum brazing filler metal with high airtightness" obtained by the above composition ratio, combined with commercially available CsF-AlF 3 Flux or KF-AlF 3 Brazing flux has excellent wettability and permeability on the surface of 3-series and 6-series high-strength aluminum alloys, excellent mechanical properties of brazing joints, and excellent air tightness. The brazed joints have passed the hydrostatic test (the water pressure is 18MPa and the pressure is maintained for 30 minutes), and the brazed joints have no leakage. The maximum pressure of the brazed joints in the hydrostatic test can reach 21 MPa (cracking at the aluminum tube).

Embodiment 3

[0029] A medium temperature aluminum solder with high air tightness, its chemical composition is: 0.05% Sr, 4.5% Si, 0.005% Ti, 0.005% Ni, 0.0005% P, 46.0% Zn , the balance being Al.

[0030] The "medium temperature aluminum brazing filler metal with high airtightness" obtained by the above composition ratio, combined with commercially available CsF-AlF 3 Flux or KF-AlF 3 Brazing flux has excellent wettability and permeability on the surface of 3-series and 6-series high-strength aluminum alloys, excellent mechanical properties of brazing joints, and excellent air tightness. The brazed joints have passed the hydrostatic test (the water pressure is 18MPa and the pressure is maintained for 30 minutes), and the brazed joints have no leakage. The maximum pressure of the brazed joints in the hydrostatic test can reach 21 MPa (cracking at the aluminum tube).

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| solidus temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com