Nano-silver composite treating agent for improving anti-pollution capacity of MBR membrane and application of nano-silver composite treating agent

A composite treatment, nano-silver technology, applied in the direction of biological water/sewage treatment, water/sludge/sewage treatment, sustainable biological treatment, etc., to achieve the effect of prolonging the interval time, strong adhesion, and good physical and chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

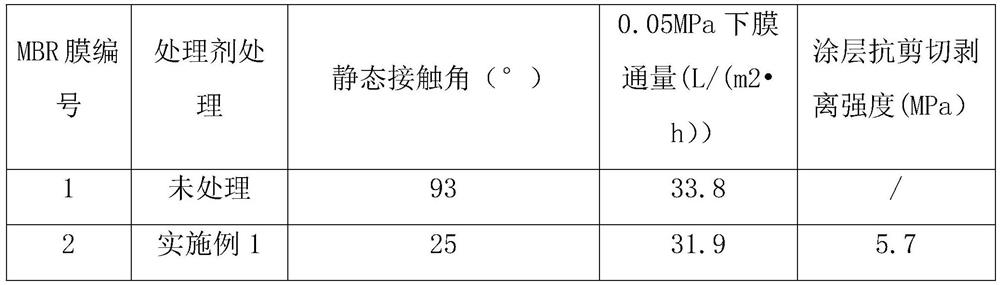

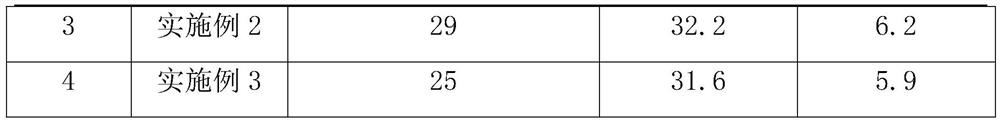

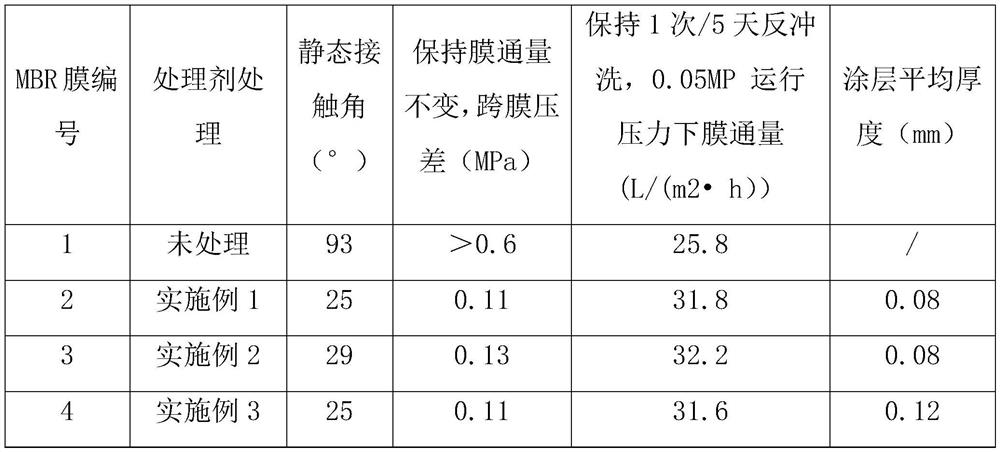

Examples

Embodiment 1

[0049] The nano-silver composite treatment agent provided by the invention includes a nano-silver material and a hydrophilic polymer. The mass ratio of the nano-silver material and the hydrophilic polymer in the treatment agent is 1:15.

[0050] The particle size of the nano-silver material in the nano-silver composite treatment agent is 10-60 nm. The raw materials for the preparation of nano-silver materials are AgNO3 (99%+), L-AA (99%+, reducing agent), PVP (polyvinylpyrrolidone, MW≈55000), ultrapure water, and absolute ethanol (analytical pure). The preparation process of nano-silver material is as follows:

[0051] 1) Add 10mL ultrapure water into a 15mL centrifuge tube, then add 0.25mL AgNO3 solution with a concentration of 10mmol / L, 0.5mL PVP solution with a concentration of 10mmol / L and 0.5mL L-AA with a concentration of 100mmol / L Reagent;

[0052] 2) Cover and tighten the cap of the centrifuge tube, and use an external vibrating mixer to mix and stir for 3 minutes, ...

Embodiment 2

[0075] As another preferred embodiment of the present invention, the difference from Example 1 is that the mass ratio of the nano-silver material and the hydrophilic polymer in the nano-silver composite treatment agent is 1:20, and all the other implementation conditions are the same as in Example 1. in the same.

Embodiment 3

[0077] As another preferred embodiment of the present invention, the difference from embodiment 1 is that the average thickness of the coating finally formed by spraying the nano-silver composite treatment agent is 0.12mm, and the rest of the implementation conditions are the same as in embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com