Wastewater treatment process and system

A wastewater treatment system and wastewater treatment technology, applied in the direction of water/sewage multi-stage treatment, oxidized water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem of low energy utilization rate, achieve high energy efficiency, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

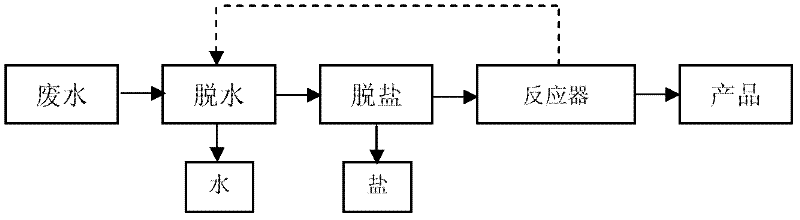

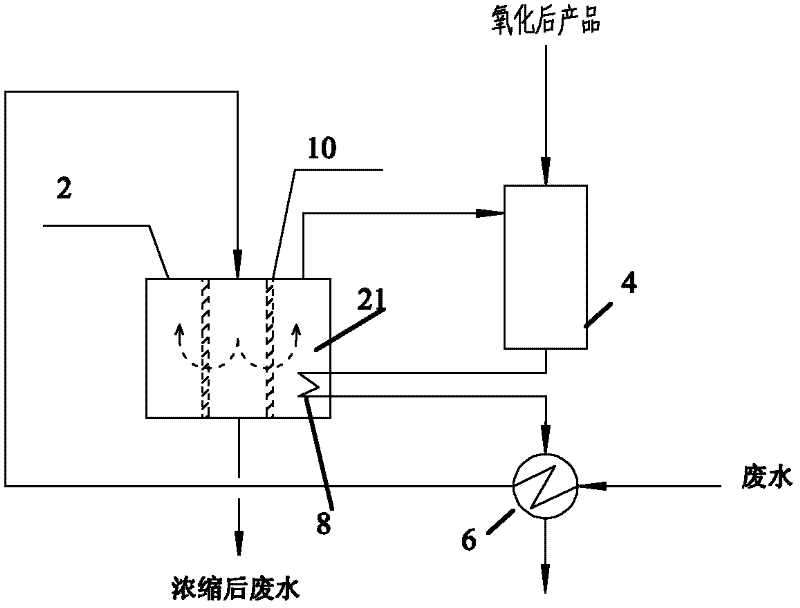

[0043] see image 3 , Dehydration treatment is carried out to waste water in membrane distillation unit 2, the temperature in membrane distillation unit 2 is controlled at 65-80 ℃, vacuum degree (the vacuum degree of the negative pressure chamber 21 of membrane distillation unit) 25-47.5Kpa, wherein. The waste water is concentrated 7 times after dehydration treatment, and the 7 times concentrated waste water is sent to the desalination device 5 by a high-pressure pump for desalination treatment. In the process of desalination treatment, the pressure of the wastewater is 22-25MPa, and the wastewater is heated to 360-380°C. At this time, more than 95% of the salt is precipitated from the water, and the salt is removed by the gravity sedimentation removal system. The desalted waste water enters the supercritical water reactor 1. In the supercritical water reactor 1, oxygen reacts with the organic matter in the waste water to form a post-reaction fluid (oxidation reactant gas) and...

Embodiment 2

[0045] The difference from Example 1 is that the oxidation product ejected from the jet vacuum pump 4 is directly introduced into the first heat exchanger 6 to heat the waste water to be supplied to the membrane distillation unit, and the oxidation product ejected from the jet vacuum pump 4 is not introduced into the membrane The negative pressure chamber 21 in the distillation device releases heat; the rest of the steps are the same as those in Example 1.

Embodiment 3

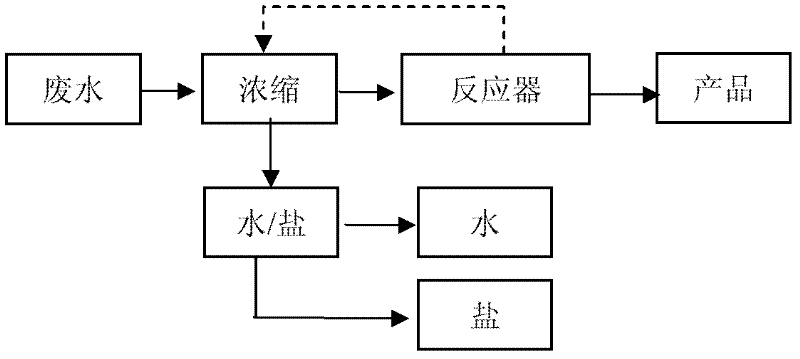

[0047] see Figure 4 , the waste water is pumped into the dehydration device for dehydration treatment. The dehydration device is a membrane distillation device 2, and the temperature in the membrane distillation device 2 is controlled at 80-95 ° C, and the vacuum degree is 47.5-84.5KPa (the vacuum degree of the negative pressure chamber of the membrane distillation device ). After dehydration treatment, the wastewater is concentrated 7 times, and the 7 times concentrated wastewater is pumped into the desalination device 5 for desalination treatment. During the desalination treatment, the pressure of the wastewater is maintained at 22-25MPa, and the wastewater is heated to 360-380°C. When most of the salt is precipitated from the water, the gravity sedimentation removes the system, and the rest of the material enters the supercritical water reactor 1. In the supercritical water reactor 1, oxygen reacts with the organic matter in the wastewater to form an oxidation reactant (re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com