Technology for treating scouring sewage and sludge

A sewage sludge and treatment process technology, applied in the direction of water/sewage multi-stage treatment, neutralized water/sewage treatment, flotation water/sewage treatment, etc., can solve the high cost of treatment, the disadvantage of using microorganisms, the increase Dealing with cost and other issues, to achieve the effect of reducing processing cost, reducing processing cost and saving cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

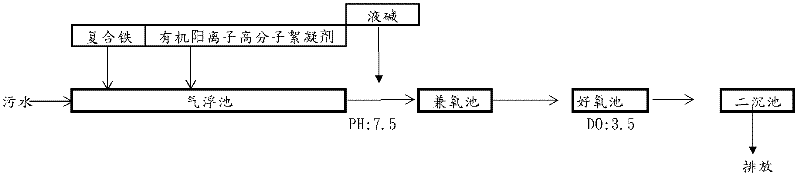

[0010] Such as figure 1 As shown, in the process for treating wool scouring sewage and sludge described in this example, the sewage is treated through air flotation tanks, facultative tanks, aerobic tanks and sedimentation tanks, wherein composite iron and organic cationic polymer flocculants are added to the air flotation tanks After the treatment is completed, lye is added to the sewage to make the pH value reach 7.5 and then enter the facultative pool, while the D0 value in the aerobic pool is controlled at 3.5. The composite iron is a mixture of ferrous sulfate, ferric hydroxide and ferric chloride, and the organic cationic polymer flocculant is cationic polyacrylamide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com