Method for treating and recycling coking wastewater

A technology for coking wastewater and water quality, which is applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., to achieve significant economic benefits and reduce the amount of replenishment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

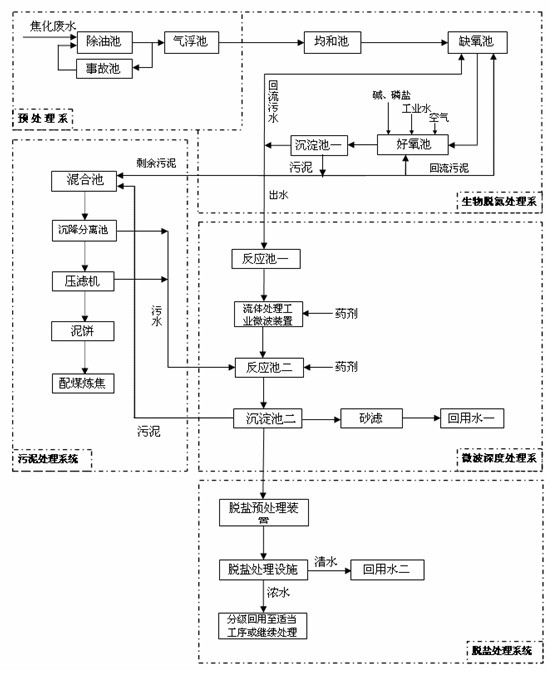

Image

Examples

Embodiment 1

[0021] A kind of coking wastewater treatment and recycling method provided by the present invention, through the following process steps:

[0022] A. Send the coking wastewater to the degreasing tank to remove heavy oil and some light oil, then send it to the air flotation tank for air flotation degreasing treatment, and then send it to the homogenization tank for water quality homogenization treatment until the water quality is as follows: pH 6, Volatile phenol is 590mg / L, cyanide is 48mg / L, petroleum is 47mg / L, COD is 3800mg / L, NH 3 -N is 590mg / L, and then sent to the anoxic tank for denitrification and denitrification treatment, so that the NO in the wastewater 3 - , NO 2 - Reduced to nitrogen and escaped into the atmosphere;

[0023] B. Send the coking wastewater treated in step A into the aerobic tank, blow in the air with a blower, replenish industrial water and return sludge from the sedimentation tank, and add industrial grade soda ash (Na 2 CO 3 ) and industrial...

Embodiment 2

[0029] A kind of coking wastewater treatment and recycling method provided by the present invention, through the following process steps:

[0030] A. Send the coking wastewater to the degreasing tank to remove heavy oil and some light oil, then send it to the air flotation tank for air flotation degreasing treatment, and then send it to the homogenization tank for water quality homogenization treatment until the water quality is as follows: pH value 12 , Volatile phenol is 570mg / L, cyanide is 47mg / L, petroleum is 46mg / L, COD is 3600mg / L, NH 3 -N is 550mg / L, and then sent to the anoxic tank for denitrification and denitrification treatment, so that the NO in the wastewater 3 - , NO 2 - Reduced to nitrogen and escaped into the atmosphere;

[0031] B. Send the coking wastewater treated in step A into the aerobic tank, blow in the air with a blower, replenish industrial water and return sludge from the sedimentation tank, and add industrial grade soda ash (Na 2 CO 3 ) and in...

Embodiment 3

[0037] A kind of coking wastewater treatment and recycling method provided by the present invention, through the following process steps:

[0038] A. Send the coking wastewater to the degreasing tank to remove heavy oil and some light oil, then send it to the air flotation tank for air flotation degreasing treatment, and then send it to the homogenization tank for water quality homogenization treatment until the water quality is as follows: pH value 10 , Volatile phenol is 600mg / L, cyanide is 50mg / L, petroleum is 50mg / L, COD is 4000mg / L, NH 3 -N is 600mg / L, and then sent to the anoxic tank for denitrification and denitrification treatment, so that the NO in the wastewater 3 - , NO 2 - Reduced to nitrogen and escaped into the atmosphere;

[0039] B. Send the coking wastewater treated in step A into the aerobic tank, blow in the air with a blower, replenish industrial water and return sludge from the sedimentation tank, and add industrial grade soda ash (Na 2 CO 3 ) and in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com