Light-weight ceramsites of riverway sludge and production method for same

A technology of river silt and lightweight ceramsite, which is applied in the field of lightweight aggregates, can solve the problems of secondary pollution of the surrounding environment, achieve the effects of reducing moisture content and organic matter content, protecting the ecological environment, and ensuring the composition of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

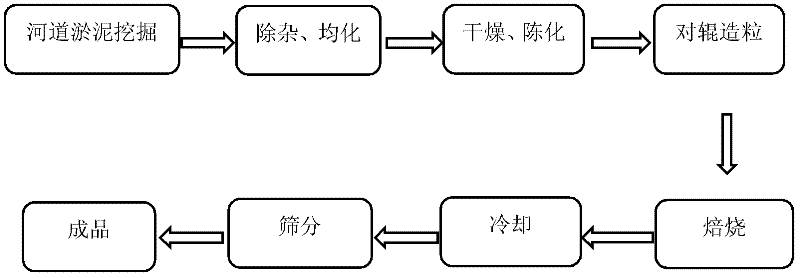

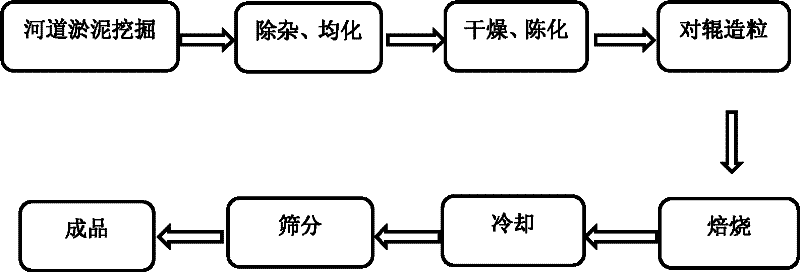

Method used

Image

Examples

Embodiment 1

[0033] Urban river dredging silt is firstly filtered to remove impurities, and then preliminarily homogenized in the silt yard. The homogenized river silt is dried in sequence and aged for at least 14 days to control the moisture content to about 15-20%. Then it is formed into balls by a double-roller granulator, and the raw meal balls made are input into a double-tube rotary kiln with a temperature of 280°C at the kiln tail. The rotating speed is 2.5-3 rpm, the rotating speed of the roasting kiln is 3-4 rpm, drying in the drying zone with a temperature of 300°C for 20 minutes, entering the preheating zone with a preheating temperature of 600°C for 15 minutes, and finally entering the After firing the firing zone at a firing temperature of 1150°C for 10 minutes, unload the hot ceramsite at a temperature of about 1000°C from the kiln head, and send it to the cooling equipment for cooling, and then the 500-grade (kg / m2) can be fired. 3 ) lightweight ceramsite.

[0034]After tes...

Embodiment 2

[0036] After removing impurities, homogenizing, drying and aging the dredged sludge of urban rivers, the moisture content is controlled to be about 20%, and then it is formed into balls by a double-roller granulator, and the raw meal balls made are input into the kiln tail at a temperature of 280°C In the double-tube rotary kiln, the inclination angle of the double-tube rotary kiln is 1.5-2 degrees, the speed of the small kiln for drying and preheating is 2.5-3 rpm, and the speed of the large kiln for roasting is 3-4 rpm. ℃ drying zone for 20 minutes, enter the preheating temperature of 600 ℃ in the preheating zone for 15 minutes, and finally enter the firing temperature of 1180 ℃ in the sintering zone for 8 minutes, and you can fire 300 grades (kg / m 3 ) lightweight ceramsite.

[0037] After testing, all the performance indexes of the lightweight ceramsite obtained in this example meet the requirements of the national standard GB2839-81 for clay ceramsite.

Embodiment 3

[0039] After removing impurities, homogenizing, drying, and aging the dredged sludge of urban rivers, the moisture content is controlled to be about 18%, and then it is formed into balls by a double-roller granulator. In the double-tube rotary kiln, the inclination angle of the double-tube rotary kiln body is 1.5-2 degrees, the speed of the small kiln for drying and preheating is 2.5-3 rpm, and the speed of the large kiln for roasting is 3-4 rpm. ℃ drying zone for 30 minutes, enter the preheating temperature of 400 ℃ in the preheating belt for 15 minutes, and finally enter the firing temperature of 1200 ℃ in the firing zone for 6 minutes, and then the 300 grade (kg / m 3 ) lightweight ceramsite.

[0040] After testing, all the performance indexes of the lightweight ceramsite obtained in this example meet the requirements of the national standard GB2839-81 for clay ceramsite.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com