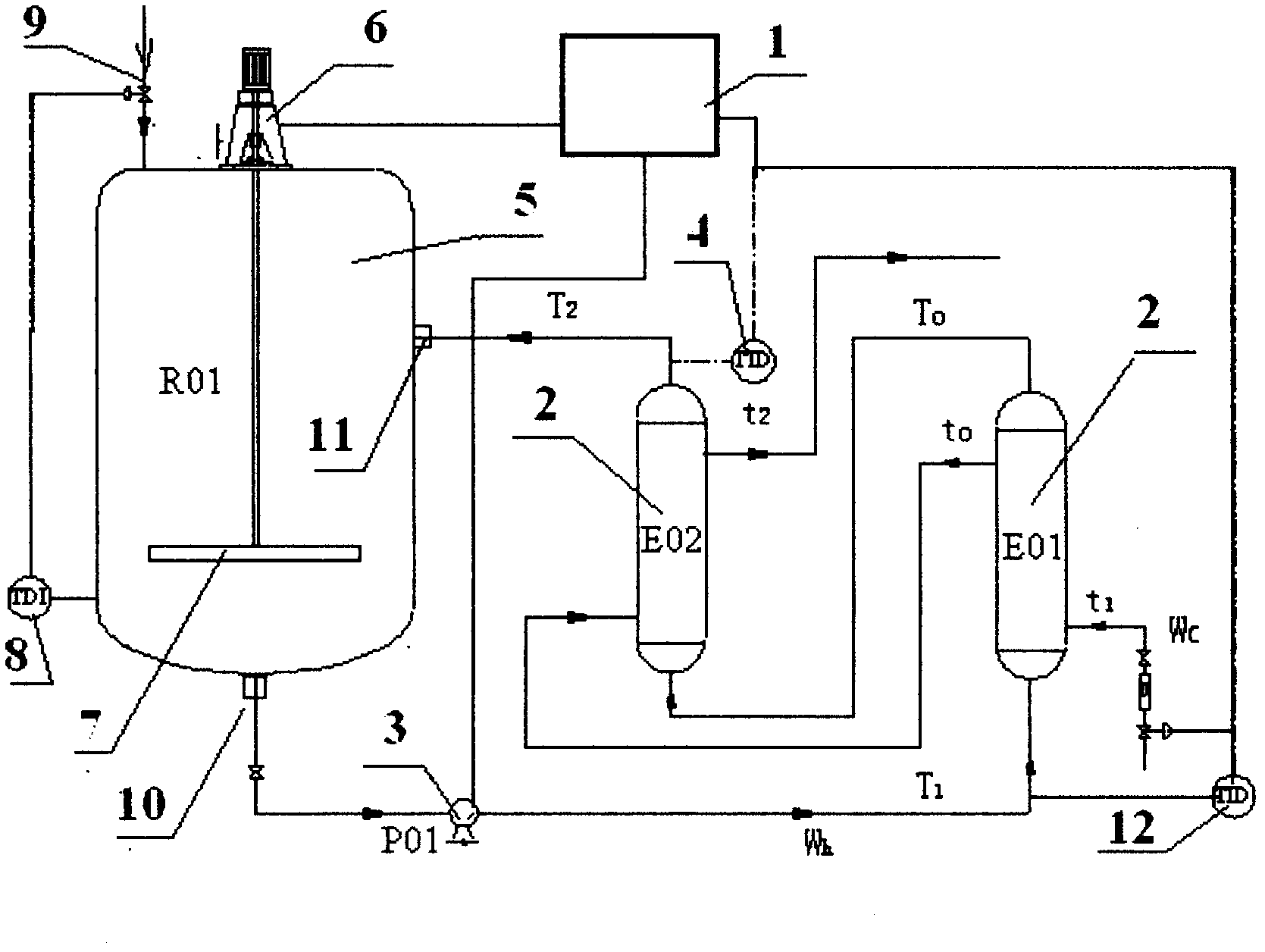

Hydrolysis outer circulation heat exchange process and device for friedel-crafts reaction liquid for synthesis of ibuprofen

A Friedel-Crafts reaction and external circulation technology, applied in the chemical industry, preparation of organic compounds, sustainable manufacturing/processing, etc. The effect of avoiding temperature fluctuation of reaction liquid, avoiding product unqualified and improving heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032]Implementation example 1: first add 1.5 tons of hydrolyzate in the hydrolysis tank, then start the circulation pump to circulate and cool the hydrolyzate through an external heat exchanger, and the flow rate of the circulated liquid is 45 tons / hour. The cooling medium of the heat exchanger is low-temperature brine, the inlet temperature of the low-temperature brine is -17°C, the outlet temperature is -12°C, and the flow rate is 20 tons / hour. After the hydrolyzate in the hydrolysis tank was cooled to 5°C, the Friedel-Crafts reaction liquid feed valve was opened for continuous feeding. By controlling the flow rate of the low-temperature brine and the feed rate of the Friedel-Crafts reaction solution, the temperature of the hydrolysis tank is stabilized at 0° C. to 10° C. during the entire hydrolysis process. The whole hydrolysis process is completed within 2 hours, and the total amount of Friedel-Crafts reaction liquid processed is 2 tons. The device operates stably witho...

Embodiment 2

[0033] Implementation example 2: first add 3 tons of hydrolyzate in the hydrolysis tank, then start the circulating pump to circulate and cool the hydrolyzate through the external heat exchanger, and the flow rate of the circulating liquid is 55 tons / hour. The cooling medium of the heat exchanger is low-temperature brine, the inlet temperature of the low-temperature brine is -12°C, the outlet temperature is -6°C, and the flow rate is 20 tons / hour. After the hydrolyzate in the hydrolysis tank was cooled to 8°C, the Friedel-Crafts reaction solution feed valve was opened for continuous feeding. By controlling the flow rate of the low-temperature brine and the feed rate of the Friedel-Crafts reaction solution, the temperature of the hydrolysis tank is stabilized at 0° C. to 10° C. during the entire hydrolysis process. The whole hydrolysis process is completed within 3 hours, and the total amount of Friedel-Crafts reaction liquid processed is 4 tons. The device operates stably wit...

Embodiment 3

[0034] Implementation example 3: first add 0.5 tons of hydrolyzate in the hydrolysis tank, then start the circulating pump to circulate the hydrolyzate through an external heat exchanger for cooling, and the flow rate of the circulating liquid is 30 tons / hour. The cooling medium of the heat exchanger is low-temperature brine, the inlet temperature of the low-temperature brine is -10°C, the outlet temperature is -5°C, and the flow rate is 12 tons / hour. After the hydrolyzate in the hydrolysis tank was cooled to 2°C, the Friedel-Crafts reaction liquid feed valve was opened for continuous feeding. By controlling the flow rate of the low-temperature brine and the feed rate of the Friedel-Crafts reaction solution, the temperature of the hydrolysis tank is stabilized at 0° C. to 10° C. during the entire hydrolysis process. The whole hydrolysis process is completed within 1 hour, and the total amount of Friedel-Crafts reaction liquid treated is 0.7 tons. The device operates stably wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com