Method for recycling metal ion from waste lithium-ion battery

A technology of lithium-ion batteries and metal ions, which is applied in the field of waste recycling, can solve the problems of environmental secondary pollution and achieve the effects of small damage, recycling and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

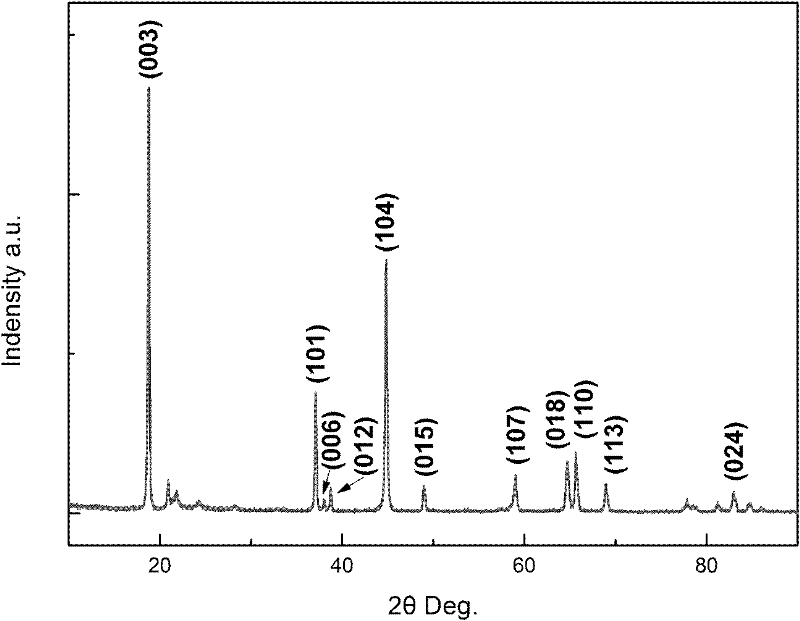

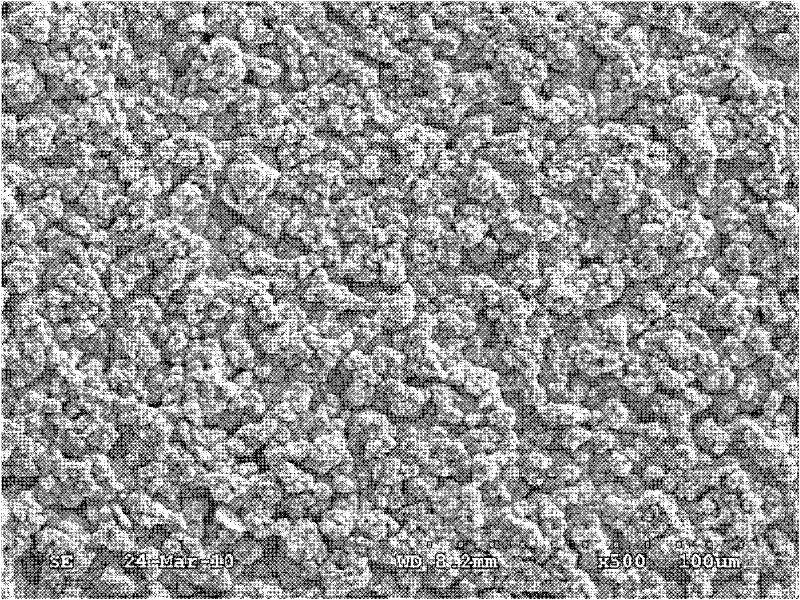

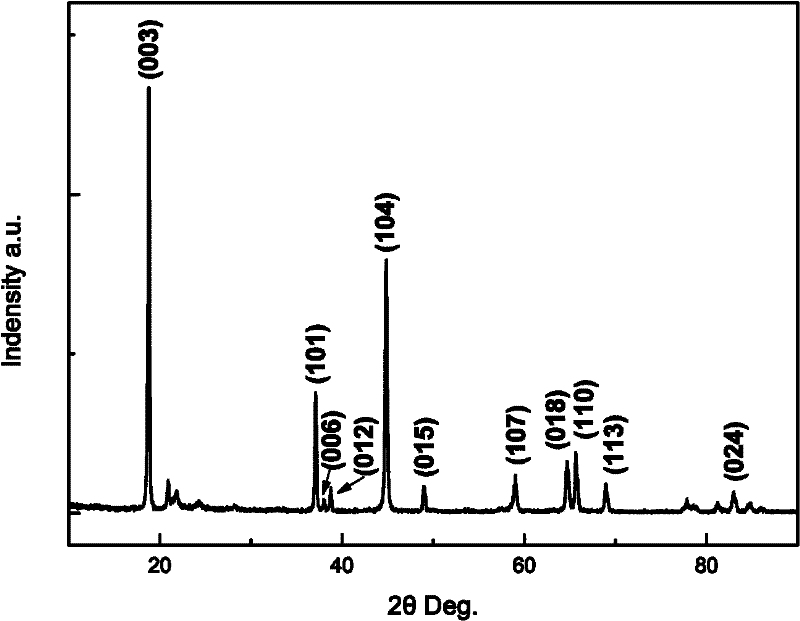

[0024] (1) Disassemble the waste lithium-ion battery manually in a fume hood after discharging, remove the iron shell and plastic skin, separate the positive and negative materials, recycle the copper foil of the negative current collector, cut the positive material into small pieces, and use NMP ultrasonic soaking treatment 1h, filter to obtain the precipitate, and recover the aluminum foil of the positive electrode collector; dry the precipitate and place it in a muffle furnace at 700°C for calcination for 5h to obtain LiCoO 2 The crude product was ball milled for 2h to obtain LiCoO 2 powder.

[0025] (2) LiCoO 2 Add the powder into 1.5M ascorbic acid solution, control the solid-liquid ratio = 25g / L, stir and react at 70°C for 20min, filter after the reaction, and obtain Li + and Co 2+ leaching solution.

[0026] Determination of Li in leaching solution by atomic absorption spectrophotometry + and Co 2+ The content of Li was calculated + and Co 2+ The leaching rates ...

Embodiment 2

[0030] (1) Disassemble the waste lithium-ion battery manually in a fume hood after discharging, remove the iron shell and plastic skin, separate the positive and negative materials, recycle the copper foil of the negative current collector, cut the positive material into small pieces, and use NMP ultrasonic soaking treatment 1h, filter to obtain the precipitate, and recover the aluminum foil of the positive electrode collector; dry the precipitate and place it in a muffle furnace at 700°C for calcination for 5h to obtain LiCoO 2 The crude product was ball milled for 2h to obtain LiCoO 2 powder.

[0031] (2) LiCoO 2 Add the powder into 0.8M ascorbic acid solution, control the solid-liquid ratio = 25g / L, stir and react at 80°C for 45min, filter after the reaction, and obtain the + and Co2+ leaching solution.

[0032] Determination of Li in leaching solution by atomic absorption spectrophotometry + and Co 2+ The content of Li was calculated + and Co 2+ The leaching rates w...

Embodiment 3

[0036] (1) Disassemble the waste lithium-ion battery manually in a fume hood after discharging, remove the iron shell and plastic skin, separate the positive and negative materials, recycle the copper foil of the negative current collector, cut the positive material into small pieces, and use NMP ultrasonic soaking treatment 1h, filter to obtain the precipitate, and recover the aluminum foil of the positive electrode collector; dry the precipitate and place it in a muffle furnace at 700°C for calcination for 5h to obtain LiCoO 2 The crude product was ball milled for 2h to obtain LiCoO 2 powder.

[0037] (2) LiCoO 2 Add the powder into 2.5M tartaric acid solution, control the solid-liquid ratio = 15g / L, stir and react at 80°C for 30min, filter after the reaction, and obtain + and Co 2+ leaching solution.

[0038] Determination of Li in leaching solution by atomic absorption spectrophotometry + and Co 2+ The content of Li was calculated + and Co 2+ The leaching rates wer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com