Process for constant temperature extracting and completely separating high purity holmium, erbium, thulium, ytterbium and lutetium

A high-purity, extraction technology, applied in the separation of thulium, holmium and lutetium concentrates, and constant temperature extraction in the field of full separation of high-purity holmium, lutetium, erbium, and ytterbium, which can solve the problem of poor heating effect, difficult automatic control, and steam energy consumption High-level problems, achieving significant economic benefits, easy connection, and simplified process conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention and its beneficial effects will be described in further detail below in conjunction with the embodiments.

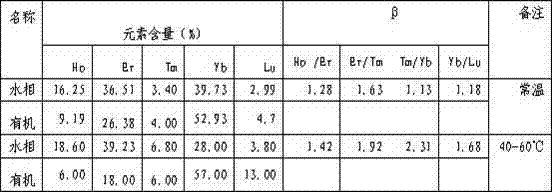

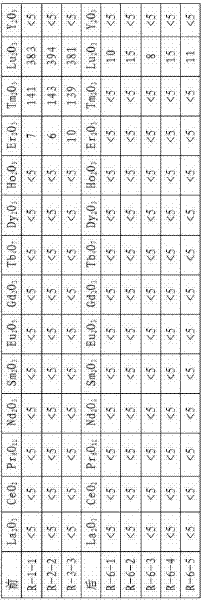

[0021] A constant-temperature extraction process for fully separating high-purity holmium, erbium, thulium, ytterbium, and lutetium. Using holmium-lutetium rare earth chloride solution as a raw material, 99.99% thulium chloride solution, 99.99% thulium chloride solution, and 99.99% % lutetium chloride solution, 99.99% ytterbium chloride solution and holmium yttrium erbium solution; the holmium yttrium erbium solution enters the P507 line after removing yttrium through the naphthenic acid line and further separates holmium erbium to obtain 99.99% holmium chloride solution and 99.99% Erbium Chloride Solution.

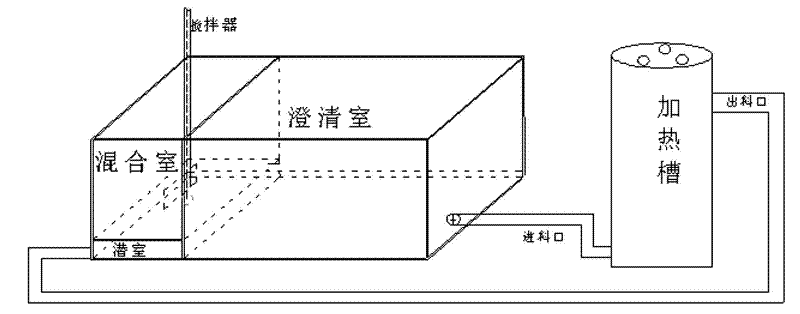

[0022] The constant temperature extraction uses constant temperature technology on the extraction separation line (such as: P507 hydrochloric acid system, naphthenic acid system and C272 hydrochloric acid system, etc.), that is, a group ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com