Method and device for measuring bonding strength between reinforcing steel and concrete under action of pre-stress

A technology of bonding strength and measuring device, applied in the direction of measuring device, mechanical device, instrument, etc., can solve the problem of no specific method of bonding strength between steel bar and concrete, achieve good sealing, wide application, and ensure sealing performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further explained below in conjunction with the drawings:

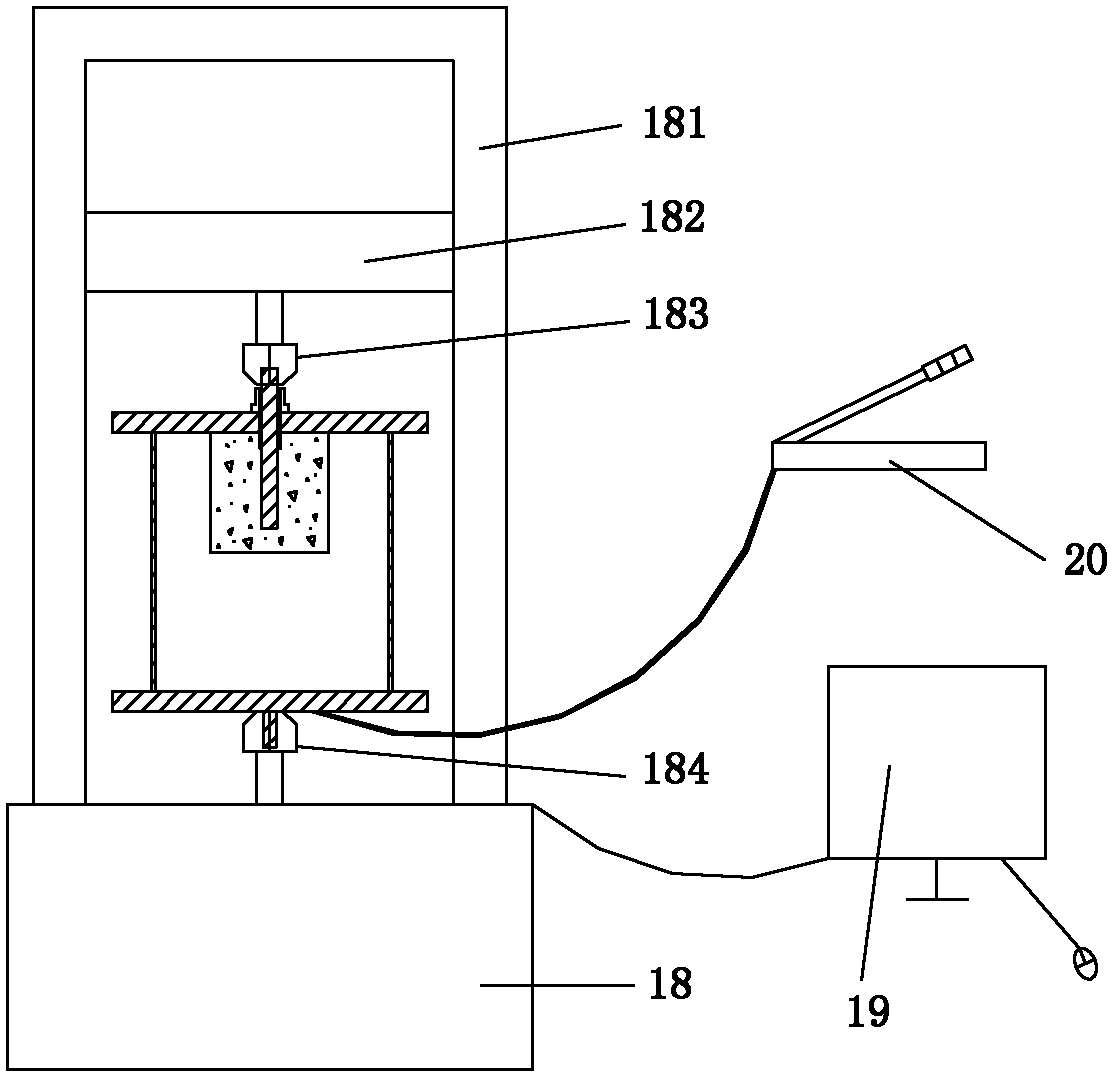

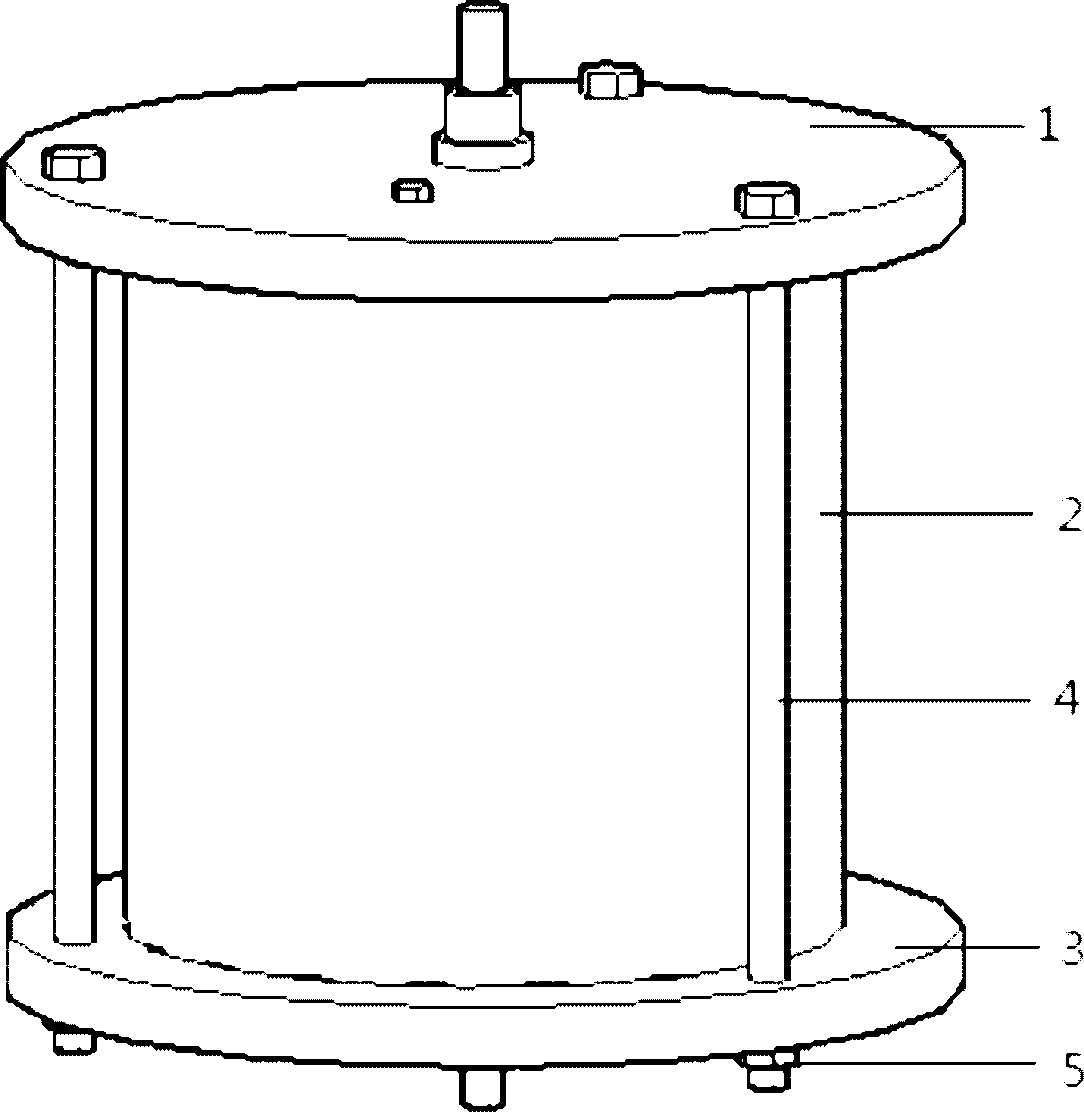

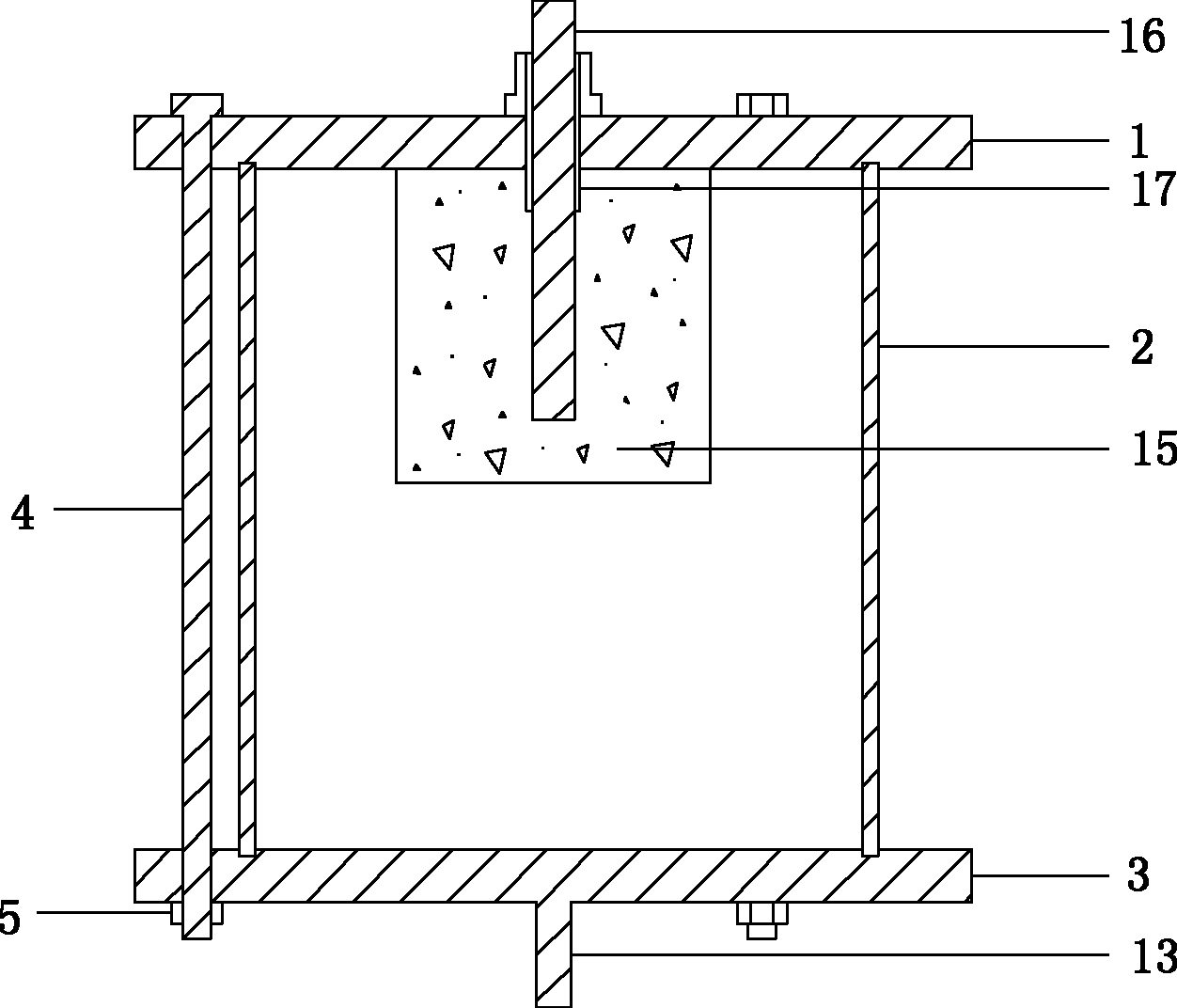

[0041] The invention first cuts the steel bar and stainless steel casing with measurement to the length required for the test (such as Picture 11 Shown) [The length of the steel bar is 230mm, and the length of the stainless steel casing is 8mm], the concrete cube specimens are poured, the specimen size is 150×150×150 (mm), and it is poured in a horizontal direction. After 24 hours of pouring, the molds were removed, and then placed in a curing room under standard conditions (room temperature 20±2°C, relative humidity above 95%), and tested after curing to age (standard curing age is 28 days). The test piece is put into the oil pressure chamber and sealed on the universal testing machine, and the oil pressure is manually increased to the required value by the SYB-2 hydraulic pump. A universal testing machine with a maximum load of 100KN is used for the measurement to ensure that the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com